Preparation method and application of trollius chinensis bunge extract

The technology of a kind of nasturtium extract and extractor, which is applied in the field of preparation of nasturtium extract, can solve problems such as the inability to fully utilize active ingredients, limited efficacy of nasturtium extract, cumbersome extraction of nasturtium, etc., so as to avoid the residue of harmful ingredients, The effect of low irritation and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

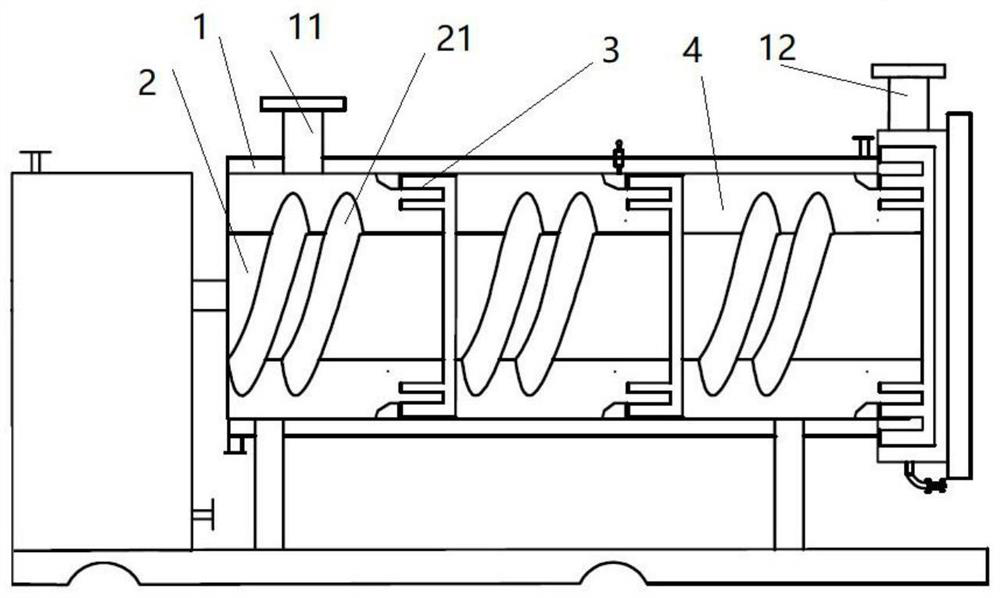

[0041] (1) Add 50kg of purified water to it after pulverizing 1kg nasturtium into a 20-purpose medicinal material powder, and stir to obtain a mixture;

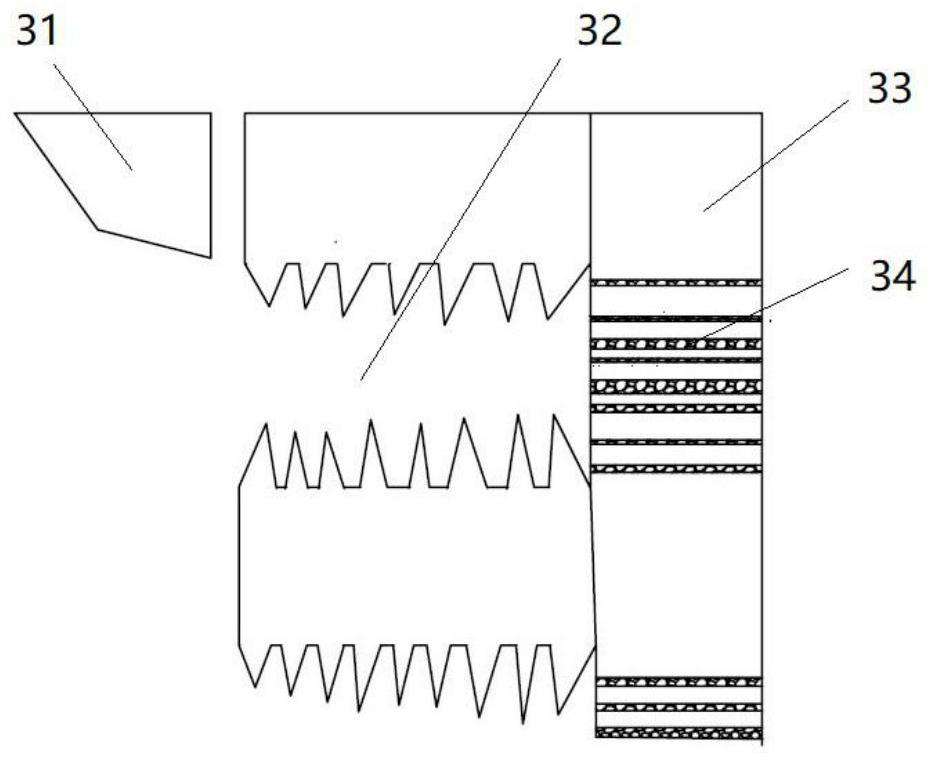

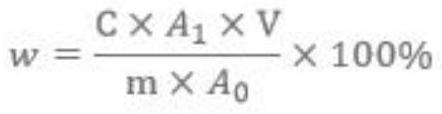

[0042] (2) The mixture is placed in a microfluidic extractor, the temperature is set at 15° C., the feed rate is 15 L / min, the rotating speed is 500 rpm, and the centrifugal stirring is carried out for 30 min, wherein the micropore diameter in the microfluidic extractor is 100 μm; (3 ) the extract is separated from the solid and liquid by a centrifuge, the rotating speed is 4000rpm, the separation liquid is collected, and the separation liquid is separated and purified by an 800nm ceramic membrane with an aperture, the filtrate is collected, and then concentrated by a reverse osmosis membrane, so that the nasturtium raw material and The mass ratio of the concentrated solution is 1:1 to obtain the product.

Embodiment 2

[0044] (1) Add purified water with a weight of 20kg to it after pulverizing 1kg nasturtium into 40 mesh medicinal powder, stir to obtain a mixture;

[0045] (2) The mixture is placed in a microfluidic extractor, the temperature is set at 10°C, the feed rate is 20L / min, the rotating speed is 800rmp, and it is centrifuged for 40min, wherein the micropore diameter in the microfluidic extractor is 500 μm; (3 ) the extract is separated from the solid and liquid by a centrifuge, the rotating speed is 2500rpm, the separation liquid is collected, and the separation liquid is separated and purified by a 500nm ceramic membrane with an aperture, the filtrate is collected, and then concentrated by a reverse osmosis membrane to make the nasturtium raw material and The mass ratio of the concentrated solution is 1:2 to obtain the product.

Embodiment 3

[0047](1) Add 250kg of purified water to it after pulverizing 10kg nasturtium into a 40-purpose medicinal material powder, stir to obtain a mixture;

[0048] (2) The mixture is placed in a microfluidic extractor, the temperature is set at 10°C, the feed rate is 20L / min, the rotating speed is 800rmp, and it is centrifuged for 40min, wherein the micropore diameter in the microfluidic extractor is 800 μm; (3 ) the extract is separated from the solid and liquid by a centrifuge, the rotating speed is 6000rpm, the separation liquid is collected, and the separation liquid is separated and purified by an 800nm ceramic membrane with an aperture, the filtrate is collected, and then concentrated by a reverse osmosis membrane, so that the nasturtium raw material and The mass ratio of the concentrated solution is 1:3 to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com