A kind of comprehensive utilization method of vinyl silane high boiler

A technology of vinyl silane and high boiling substances, which is applied in the field of comprehensive utilization of organosilicon by-products, can solve the problems of unknown, solid matter and trace platinum group metal treatment instructions, and achieve small reagent consumption, significant economic benefits and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

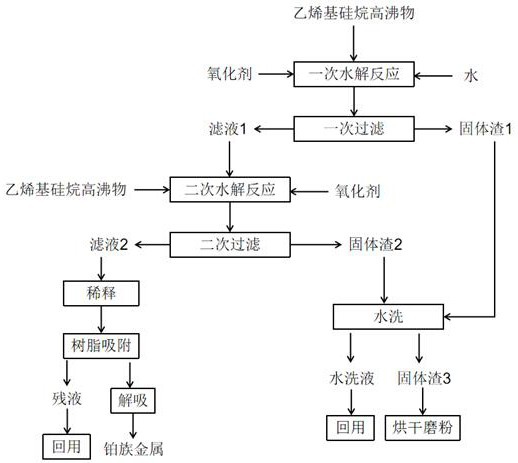

Method used

Image

Examples

Embodiment 1

[0027] Step (1): One hydrolysis reaction, mix 1L vinylsilane high boiler with 6L water, 20gNaClO 3 Mix and stir for 120min at a speed of 300r / min to fully react;

[0028] Step (2): Once filtered, the fully reacted solution was filtered for solid-liquid separation: the obtained solid residue was 2296g, after being washed twice to neutrality, the main component was analyzed and detected to be SiO 2 , the metal platinum content has been reduced to 0.69mg / t. Dry the washed solid slag at 100°C for 4 hours, and then grind it with a ball mill to a particle size below 200 mesh. It can be used as metallurgical auxiliary materials or sold to glass and cement manufacturers. . Filter gained filtrate 4330ml, and its acidity is 3.7mol / L, contains platinum 19.1mg / L in the analysis detection filtrate.

[0029] Step (3): secondary hydrolysis reaction, after mixing the water of filtrate 4330ml and 1670ml described in the step (2) to obtain a new solvent, with new 1kg vinylsilane high boiler a...

Embodiment 2

[0034] In the primary hydrolysis reaction of step (1), 1L vinylsilane high boiler is mixed with 5.4L water, 18g H 2 o 2 Mix and fully stir to make the reaction complete; for the secondary hydrolysis reaction of step (3), the filtrate obtained in step (2) is added with water to obtain 5.4L new solvent, and with new 1kg vinylsilane high boiler and 18g H 2 o 2 Mix and fully stir to make the reaction complete; the resin in step (5) is adsorbed, and the filtrate obtained in step (4) is diluted 8 times, and the metal platinum therein is adsorbed by an anion exchange resin; the solid slag obtained in step (5) is 3 Dry it at 100°C for 6 hours, and then grind it with a ball mill to a particle size below 200 mesh. It is used for the production of glass or as a metallurgical auxiliary material. All the other operations are the same as in Example 1.

Embodiment 3

[0036] In the primary hydrolysis reaction of step (1), with 1L vinylsilane high boiler and 7L water, 16g HNO 3 Mix and fully stir to make the reaction complete; for the secondary hydrolysis reaction of step (3), the filtrate obtained in step (2) is added with water to obtain 7L new solvent, and with new 1kg vinylsilane high boiler and 16g H 2 o 2Mix and fully stir to make the reaction complete; the resin in step (5) is adsorbed, and the filtrate obtained in step (4) is diluted 12 times, and the metal platinum therein is adsorbed by an anion exchange resin; the solid slag obtained in step (5) is 3 Dry it at 100°C for 8 hours, and then grind it with a ball mill to a particle size below 200 mesh. It is used for the production of glass or as a metallurgical auxiliary material. All the other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com