A kind of method for removing impurity ions in liquid ammonia

A technology for impurity ions and liquid ammonia, which is used in the preparation/separation of ammonia, chemical instruments and methods, ammonia compounds, etc., and can solve problems such as the difficulty of removing boron and calcium elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for removing impurity ions in liquid ammonia, the scheme of which is:

[0029] Step 1: Adsorption and complexation, add 0.5kg of modified MCM-41 molecular sieve to 50kg of liquid ammonia, stir and mix evenly, add 0.1kg of polyhydric alcohol, and mix and adsorb for 2h. The method for preparing the modified MCM-41 molecular sieve for:

[0030] After taking 100-120 parts of MCM-41 molecular sieves and refluxing 300-400 parts of nitric acid at 80-90 ° C for 4-6 hours, filtered, washed with water, and dried to obtain activated MCM-41 molecular sieves;

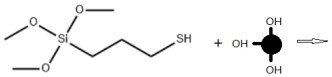

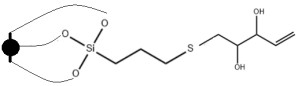

[0031] Place 100-120 parts of activated MCM-41 molecular sieves in 500-1000 parts of ethanol aqueous solution, add 2-5 parts of γ-mercaptopropyltrimethoxysilane (KH590), stir mechanically at room temperature for 2-4 hours, filter , washed with water, and dried to obtain MCM-41 molecular sieve chemically modified by thiol groups;

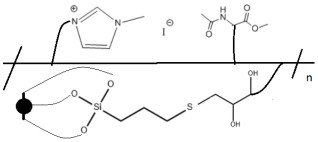

[0032] 100-120 parts of sulfhydryl chemically modified MCM-41 molecular sieves were p...

Embodiment 2

[0037] A method for removing impurity ions in liquid ammonia, the scheme of which is:

[0038] Step 1: Adsorption and complexation: Add 2.5kg of modified MCM-41 molecular sieve to 65kg of liquid ammonia, stir and mix evenly, add 0.3kg of polyhydric alcohol, and mix and absorb for 3.5h. The modified MCM-41 molecular sieve is prepared The method is:

[0039] After taking 100-120kg MCM-41 molecular sieve and refluxing 300-400kg nitric acid at 80-90°C for 4-6 hours, filter, wash with water and dry to obtain MCM-41 molecular sieve after active treatment;

[0040] Place 100-120kg of activated MCM-41 molecular sieves in 500-1000kg of ethanol aqueous solution, add 2-5kg of γ-mercaptopropyltrimethoxysilane (KH590), stir mechanically at room temperature for 2-4h, filter, wash with water, and dry , to obtain MCM-41 molecular sieve chemically modified by thiol groups;

[0041] 100-120kg of sulfhydryl chemically modified MCM-41 molecular sieves were placed in 20-30kg of methyl 2-acetamid...

Embodiment 3

[0047] A method for removing impurity ions in liquid ammonia, the scheme of which is:

[0048] Step 1, adsorption and complexation, add 5kg of modified MCM-41 molecular sieve to 80kg of liquid ammonia, stir and mix evenly, add 0.5kg of polyhydric alcohol, and mix and adsorb for 5h. The preparation method of the modified MCM-41 molecular sieve is as follows: :

[0049] After taking 100-120kg MCM-41 molecular sieve and refluxing 300-400kg nitric acid at 80-90°C for 4-6 hours, filter, wash with water and dry to obtain MCM-41 molecular sieve after active treatment;

[0050] Place 100-120kg of activated MCM-41 molecular sieves in 500-1000kg of ethanol aqueous solution, add 2-5kg of γ-mercaptopropyltrimethoxysilane (KH590), stir mechanically at room temperature for 2-4h, filter, wash with water, and dry , to obtain MCM-41 molecular sieve chemically modified by thiol groups;

[0051] 100-120kg of sulfhydryl chemically modified MCM-41 molecular sieves were placed in 20-30kg of methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com