Toughening type waterborne epoxy curing agent as well as preparation method and application thereof

A water-based epoxy and toughening technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve problems such as no good, achieve good stability and construction performance, easy operation, and strong industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Pour 100g of dimer acid into the kettle, then inject 135g of epoxy resin E51, stir evenly, add the catalyst triphenylphosphine, react at a constant temperature of 100°C for 3 hours, and discharge to obtain toughened epoxy resin A1. Wherein, the molar ratio n1 of the total amount of epoxy groups in the epoxy resin to the total amount of carboxyl groups in the dimer acid is 2:1.

Embodiment 2-4

[0060] Prepare toughening type epoxy resin respectively according to the method in preparation example 1, be denoted as A2 and A3, A4, and its reaction condition is as shown in table 2:

[0061] Different reaction conditions in table 2, preparation embodiment 1-4

[0062]

[0063] [Example 1] (i.e. S1)

[0064] Follow the steps below to prepare a waterborne epoxy curing agent:

[0065] Step A: Add 80g of epoxy resin E51 and 20g of toughened epoxy resin A1 into a beaker, stir evenly, add 300g of isophoronediamine into the reaction bottle, and preheat the temperature to 80°C; The resin component was gradually dropped into the reaction bottle to carry out the ring-opening reaction. The dropping time was 2 hours, and the temperature was continued for 1 hour after the dropping; Phoronediamine removal.

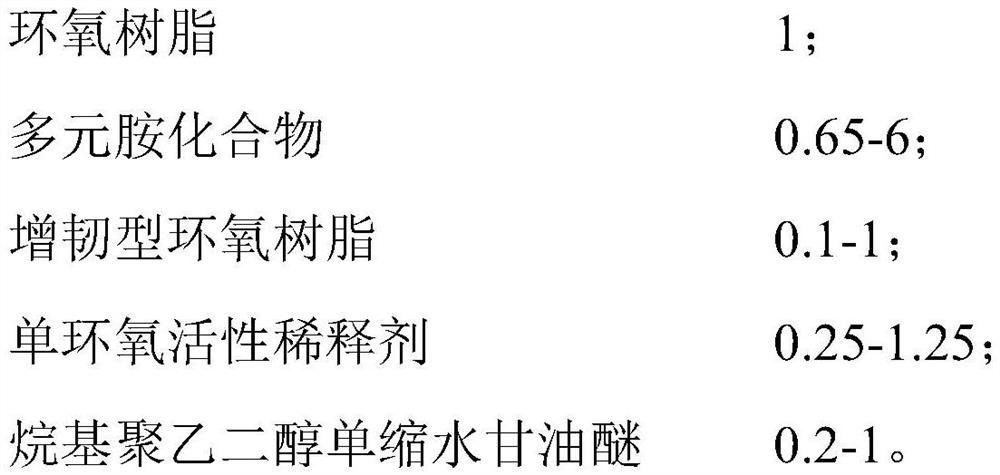

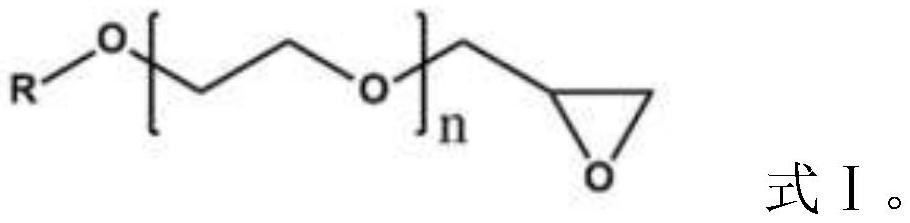

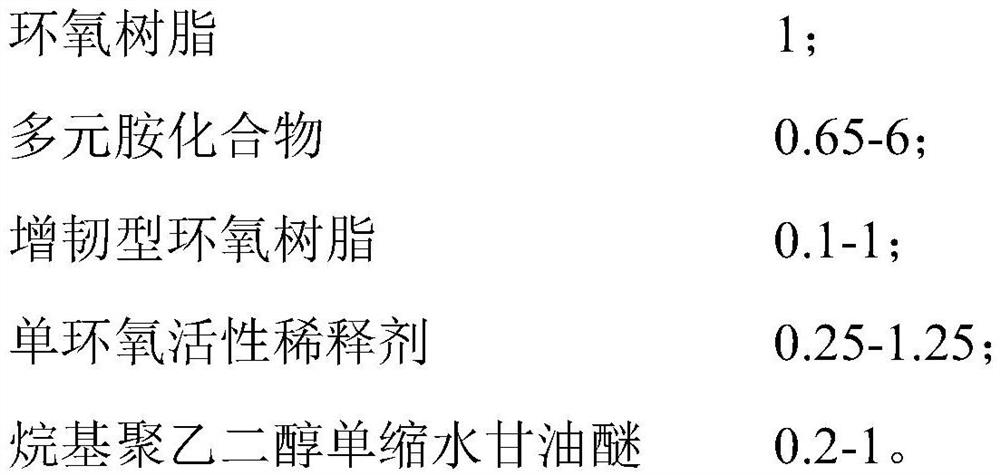

[0066] Step B, then add 35g propylene glycol methyl ether into the system, and then use a peristaltic pump to gradually drop 52g butyl glycidyl ether and 80g methoxypolyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com