A high-temperature high-emissivity infrared radiation coating and its preparation method and application method

An infrared radiation coating and high-emissivity technology, which is applied in the field of high-temperature high-emissivity infrared radiation coating and its preparation, can solve the problems of short effective working time of infrared radiation coating, easy growth of nano-powder, and rapid decay of emissivity, etc. Problems, to achieve the effect of low cost, long service life, convenient spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

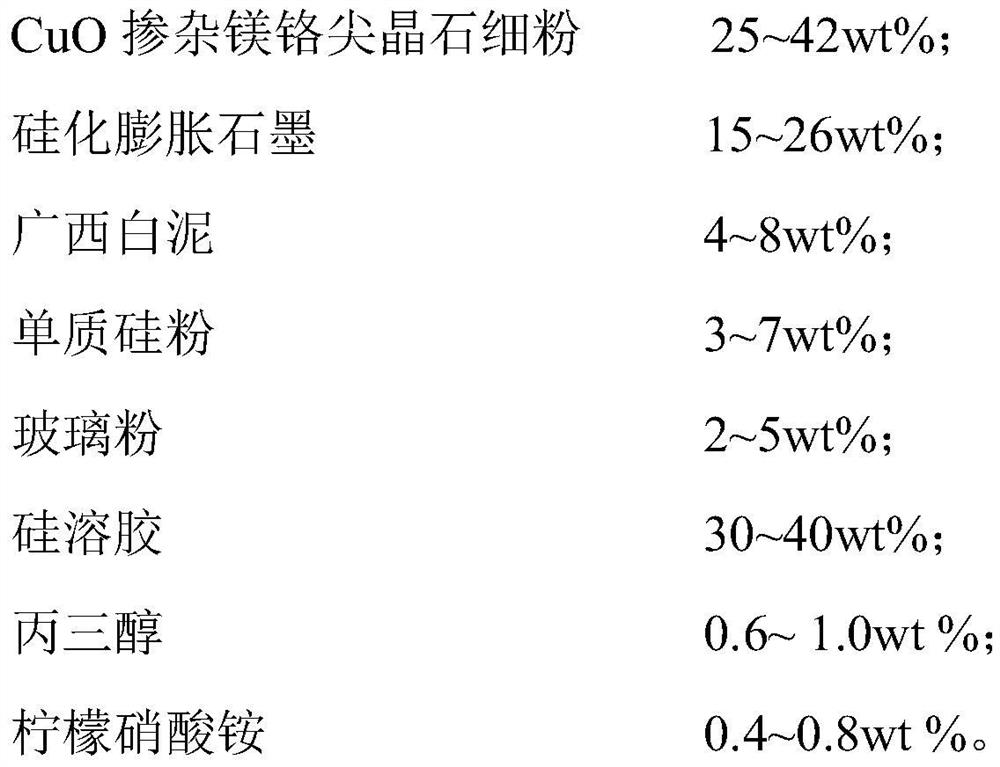

[0037] A high-temperature and high-emissivity infrared radiation coating and its preparation method and application method. The preparation method described in this embodiment and the method of use are:

[0038]

[0039]

[0040] According to the raw materials and content of the high-temperature high-emissivity infrared radiation coating, mixing with a planetary ball mill, the ball-to-material ratio is 2-3:1, and mixing for 0.5-1 hour to obtain the high-temperature high-emissivity infrared radiation coating.

[0041] The preparation method of described CuO doped magnesium chromium spinel fine powder is:

[0042] Magnesium oxide, copper oxide and chromium oxide are used as raw materials, the raw materials are placed in a planetary ball mill, absolute ethanol is used as a ball milling medium, ball milled for 8-9 hours, dried, and pressed into a green body under the condition of 10-20 MPa. Insulate at 1150-1250°C for 3-4 hours, cool naturally with the furnace, crush, and s...

Embodiment 2

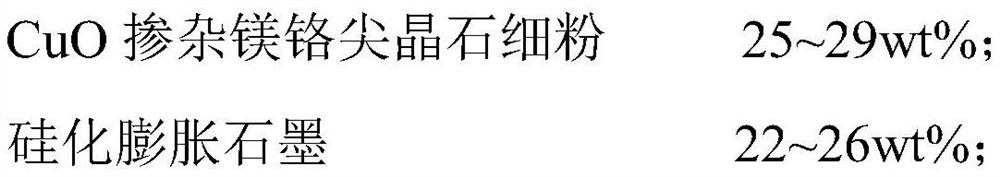

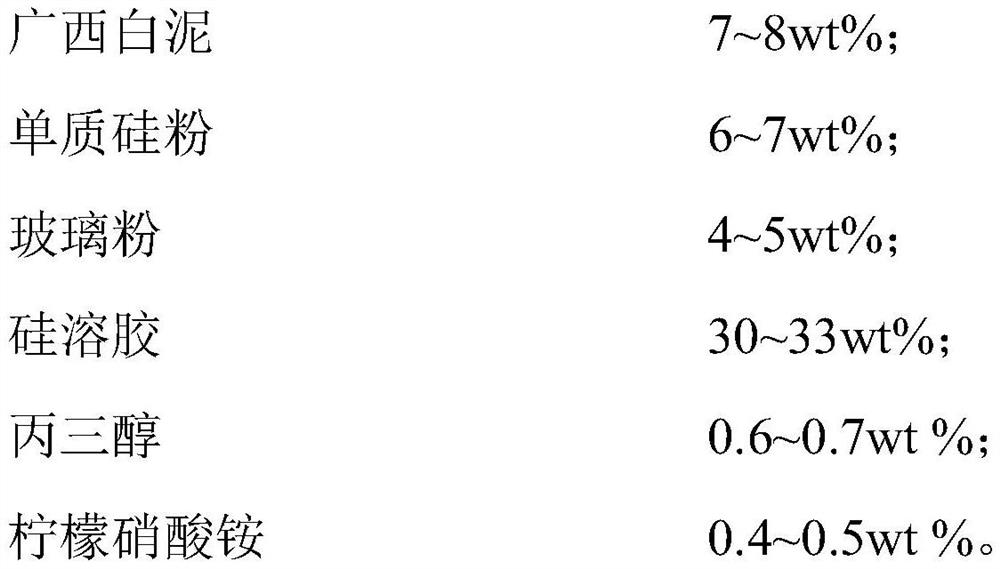

[0048] A high-temperature and high-emissivity infrared radiation coating and its preparation method and application method. The preparation method described in this embodiment and the method of use are:

[0049]

[0050] According to the raw materials and content of the high-temperature high-emissivity infrared radiation coating, mixing with a planetary ball mill, the ball-to-material ratio is 2-3:1, and mixing for 1-1.5 hours to obtain the high-temperature high-emissivity infrared radiation coating.

[0051] The preparation method of described CuO doped magnesium chromium spinel fine powder is:

[0052] Using magnesium oxide, copper oxide and chromium oxide as raw materials, putting the raw materials in a planetary ball mill, using absolute ethanol as a ball milling medium, ball milling for 9-10 hours, drying, and pressing under the condition of 20-30MPa to form a green body. Insulate at 1250-1350°C for 4-5 hours, cool naturally with the furnace, crush, and sieve to a par...

Embodiment 3

[0058] A high-temperature and high-emissivity infrared radiation coating and its preparation method and application method. The preparation method described in this embodiment and the method of use are:

[0059]

[0060] According to the raw materials and content of the high-temperature high-emissivity infrared radiation coating, mixing with a planetary ball mill, the ball-to-material ratio is 3-4:1, and mixing for 1-1.5 hours to obtain the high-temperature high-emissivity infrared radiation coating.

[0061] The preparation method of described CuO doped magnesium chromium spinel fine powder is:

[0062] Using magnesium oxide, copper oxide and chromium oxide as raw materials, placing the raw materials in a planetary ball mill, using absolute ethanol as a ball milling medium, ball milling for 10-11 hours, drying, and pressing under the condition of 25-35 MPa to form a green body. Insulate at 1300-1400°C for 4-5 hours, cool naturally with the furnace, crush, and sieve to a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com