A kind of composite antibacterial finishing non-woven fabric and preparation method thereof

A non-woven fabric and composite antibacterial technology, applied in botany equipment and methods, textiles and papermaking, fiber treatment, etc., can solve the problems of poor durability of multifunctional fabrics, adhesive pollution, single performance, etc., and achieve strong antibacterial power , high-efficiency filtration, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

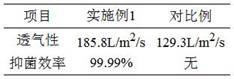

Embodiment 1

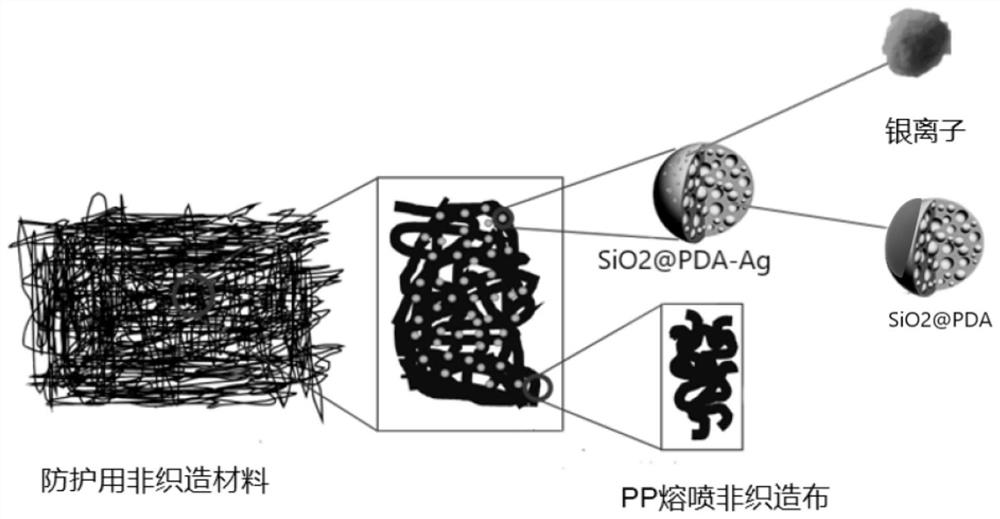

[0033] A SiO-based 2 @PDA-Ag composite antibacterial finishing non-woven fabric, the preparation method of the non-woven fabric comprises the following steps:

[0034] (1) Preparation of porous nano-silica by sol-gel method;

[0035] Mix 15mL of ammonia water, 50mL of deionized water and 150mL of absolute ethanol evenly, add 45mL of tetraethyl silicate TEOS while stirring, stir and react at room temperature for 24 h, and obtain nano-SiO with light blue opalescence. 2 ethanol dispersion;

[0036] After filtering, the precipitate was centrifuged and washed three times with ethanol and deionized water, vacuum-dried at 30° C., and calcined at 550° C. for 3 hours in a muffle furnace to obtain the porous nano-silica.

[0037] (2) Preparation of modified materials with polydopamine film attached to the surface, that is, SiO 2 @PDA;

[0038] At 45°C, put the porous silica prepared in step (1) directly into a dopamine solution with a concentration of 2g / L and a pH of 8.5 and soak f...

Embodiment 2

[0044] A SiO-based 2 @PDA-Ag composite antibacterial finishing non-woven fabric, the preparation method of the non-woven fabric comprises the following steps:

[0045] (1) Preparation of porous nano-silica by sol-gel method;

[0046] Mix 15mL of ammonia water, 50mL of deionized water and 200mL of absolute ethanol evenly, add 45mL of tetraethyl silicate TEOS while stirring, stir and react at room temperature for 24 h, and obtain nano-SiO with light blue opalescence. 2 ethanol dispersion;

[0047] After filtering, the precipitate was centrifuged and washed three times with ethanol and deionized water, vacuum-dried at 45° C., and calcined at 400° C. for 3 hours in a muffle furnace to obtain the porous nano-silica.

[0048] (2) Preparation of modified materials with polydopamine film attached to the surface, that is, SiO 2 @PDA;

[0049] At 55°C, put the porous silica prepared in step (1) directly into a dopamine solution with a concentration of 2g / L and a pH of 8.5 and soak f...

Embodiment 3

[0055] A SiO-based 2 @PDA-Ag composite antibacterial finishing non-woven fabric, the preparation method of the non-woven fabric comprises the following steps:

[0056] (1) Preparation of porous nano-silica by sol-gel method;

[0057] Mix 15mL of ammonia water, 50mL of deionized water and 200mL of absolute ethanol evenly, add 45mL of tetraethyl silicate TEOS while stirring, stir and react at room temperature for 24 h, and obtain nano-SiO with light blue opalescence. 2 ethanol dispersion;

[0058] After filtering, the precipitate was centrifuged and washed three times with ethanol and deionized water, vacuum-dried at 40° C., and calcined at 500° C. for 3 hours in a muffle furnace to obtain the porous nano-silica.

[0059] (2) Preparation of modified materials with polydopamine film attached to the surface, that is, SiO 2 @PDA;

[0060] At 60°C, put the porous silica prepared in step (1) directly into a dopamine solution with a concentration of 2g / L and a pH of 8.5 and soak f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com