Laminated composite fireproof protection plate

A protection board and laminated technology, applied in covering/lining, construction, building structure, etc., can solve the problems of poor durability and fire resistance, poor collision and wear ability, difficult maintenance and management, etc., and achieve long fire-resistant time, The effect of improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

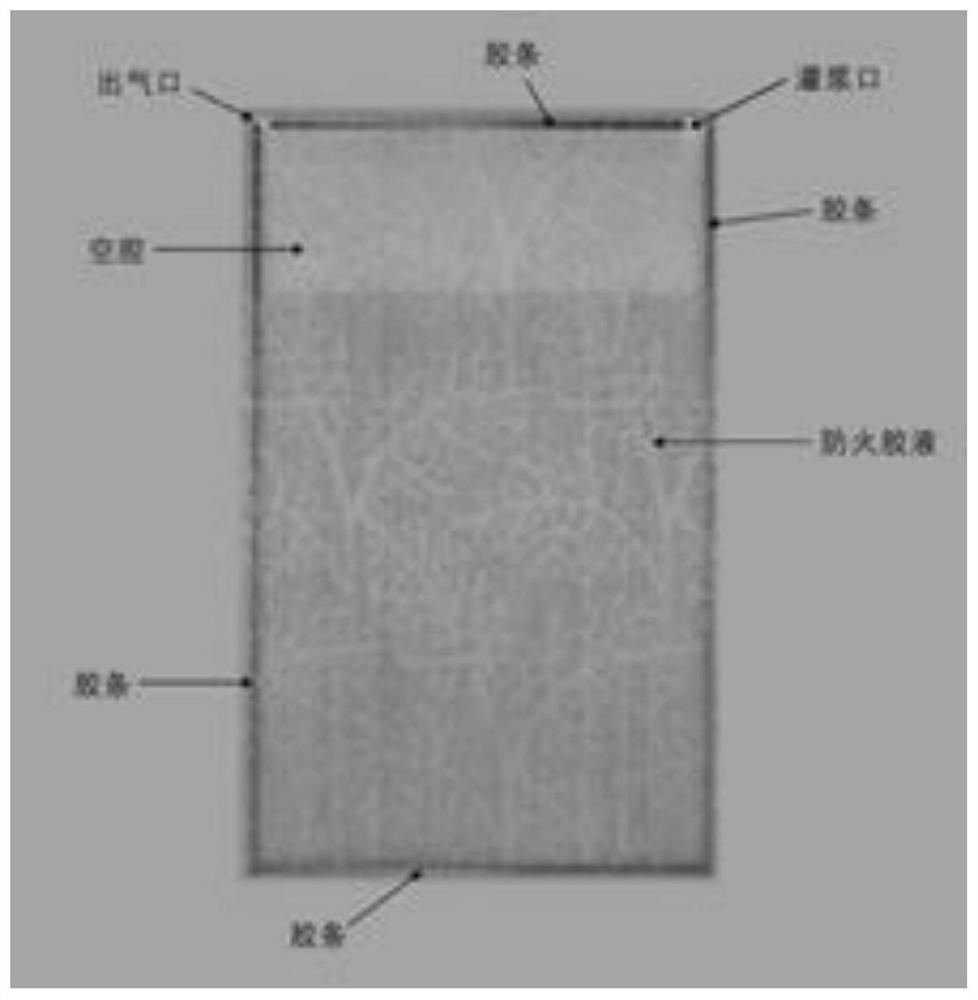

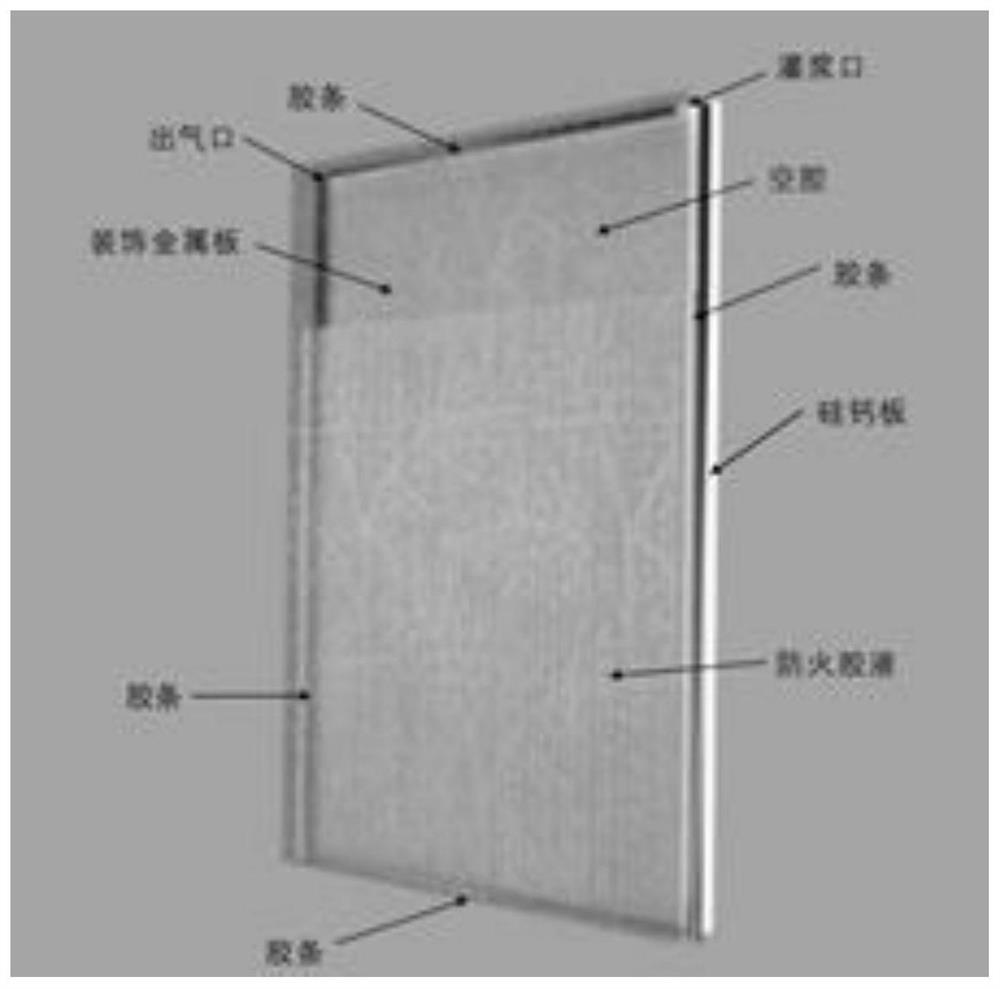

[0030] In the preparation process of the above laminated composite fireproof protection board, the substrate, the flame retardant sealing strip and the decorative board are first assembled into a cavity, and then the fireproof glue is filled in the cavity. After curing, the fireproof glue is combined with the substrate and the decorative board Bonded into one body to form a laminated composite fire protection board. The curing temperature is 20-100° C., and the time is 1-24 hours. More specifically, the curing temperature is 30-80° C., and the time is 2-18 hours.

[0031] This application provides a laminated composite fireproof protection board, which uses fireproof glue, a substrate with fireproof function, a decorative board and a flame-retardant sealing strip to construct a laminated composite fireproof board, which is not only a further improvement on the basis of traditional fireproof boards The fire-resistant and heat-resistant performance is improved, and the quality p...

Embodiment 1

[0036] First, assemble the hard calcium silicate board, the flame retardant sealing strip and the decorative metal aluminum board into a cavity;

[0037]Add glycerin and polyethylene glycol to the silica sol containing aluminum and magnesium salts with a water content of 30%, with a mass ratio of 15:2:2, stir at a temperature of 40°C at a speed of 10r / s for 20min; then add epoxy Propane (the mass ratio of propylene oxide to glycerin is 1:1), stirred at 40°C for 50 minutes; then the above mixed solution was lowered to room temperature, and the obtained liquid was fireproof glue;

[0038] Fill the fireproof glue into the cavity assembled by hard calcium silicate board, flame retardant sealing strip and metal aluminum plate with decorative effect; the thickness of the selected hard calcium silicate board is 8mm, the thickness of fireproof glue is 5mm, and the flame retardant sealing strip The rubber material is dense rubber, the cross section of the flame retardant sealing strip ...

Embodiment 2

[0042] First, assemble the hard calcium silicate fireproof board, flame-retardant sealing strip and metal aluminum plate with decorative effect into a cavity;

[0043] The fireproof glue prepared in Example 1 is poured into the cavity assembled by hard calcium silicate fireproof board, flame retardant sealing strip and metal aluminum plate with decorative effect; wherein the thickness of hard calcium silicate board is 10mm, and the thickness of the flame retardant sealing strip is The rubber material is dense rubber, the section of the flame-retardant sealing rubber strip is sheet-shaped, the thickness of the fire-resistant rubber is 6mm, and the thickness of the galvanized plate is 1mm.

[0044] For the multi-layer fire protection board prepared in Example 2 of the present invention, after the fire resistance test, the fire resistance time of the product is 4h; the surface density is about 16.9Kg / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com