Supercritical fluid drilling and blasting integrated double-arm drill jumbo and control method thereof

A technology of supercritical fluid and rock drilling rigs, which is applied to drilling equipment and methods, blasting, earthwork drilling and mining, etc., which can solve problems such as insufficient construction efficiency and construction quality, low degree of mechanization, and poor safety, and improve construction efficiency. Efficiency and construction quality, high level of mechanization, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

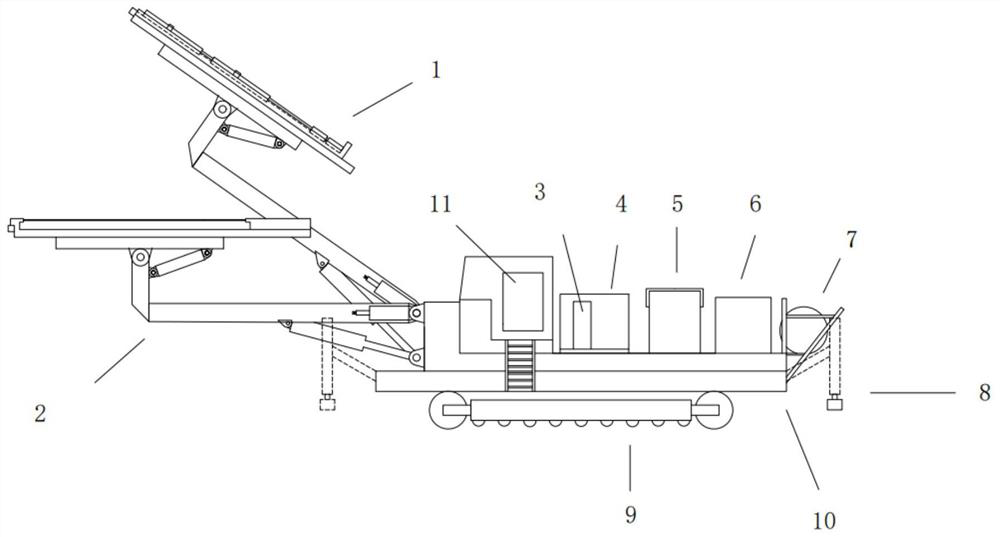

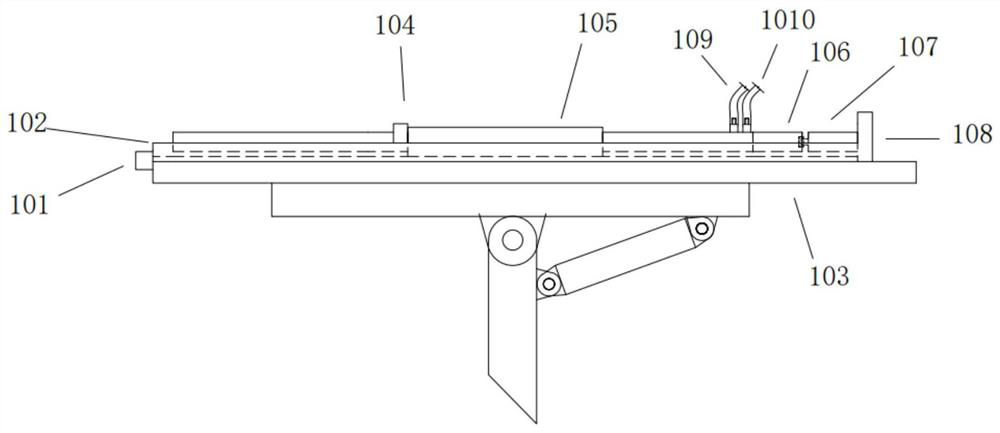

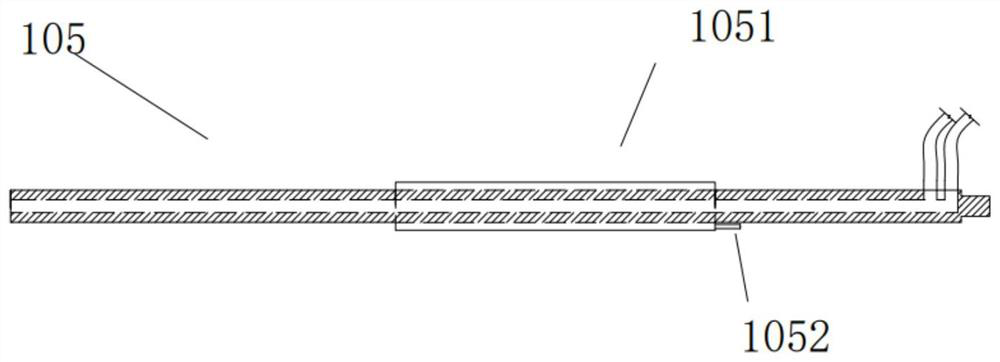

[0038] Such as figure 1 As shown, a supercritical fluid (hydrothermal) drilling and blasting integrated dual-arm rock drilling jumbo of the present invention includes a pre-split arm 1, a drill arm 2, a storage tank 4, a motor 5, an oil pump 6, an oil tank 7, Outrigger 8, crawler chassis 9, bearing platform 10 and operating room 11. Wherein, the pre-split arm 1 and the drill arm 2 are respectively used for fracturing and drilling, and the pre-split arm 1 and the drill arm 2 are respectively connected to both sides of the front end of the operating room 11. The operating room 11 is provided with personnel seats, an operating platform and a computer. A storage tank 4 , a motor 5 , an oil pump 6 and an oil tank 7 are arranged in sequence at the rear end of the operating room 11 , and are all arranged above the platform 10 . Liquid gas is stored in storage tank 4, and motor 5 provides power for the positioning and drilling of drilling arm 2 and pre-split arm 1, and oil tank 7 st...

Embodiment 2

[0050] In this embodiment, the mixed-phase fluid used is liquid nitrogen, and what is stored in the storage tank 4 is liquid nitrogen. Other structures, connection methods and manipulation methods are the same as those in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com