Original austenite grain boundary corrosion method of martensitic stainless steel for steam turbine bolt

A martensitic stainless steel and austenite grain boundary technology, which is applied in the field of prior austenite grain boundary corrosion of martensitic stainless steel used for steam turbine bolts, can solve the problem of not being able to show the prior austenite grain boundary, corrosive agent and corrosion resistance of the material. The lack of corrosion methods, inapplicability and other problems, to achieve the effect of promoting corrosion and tissue exposure, saving operation time, and reducing corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

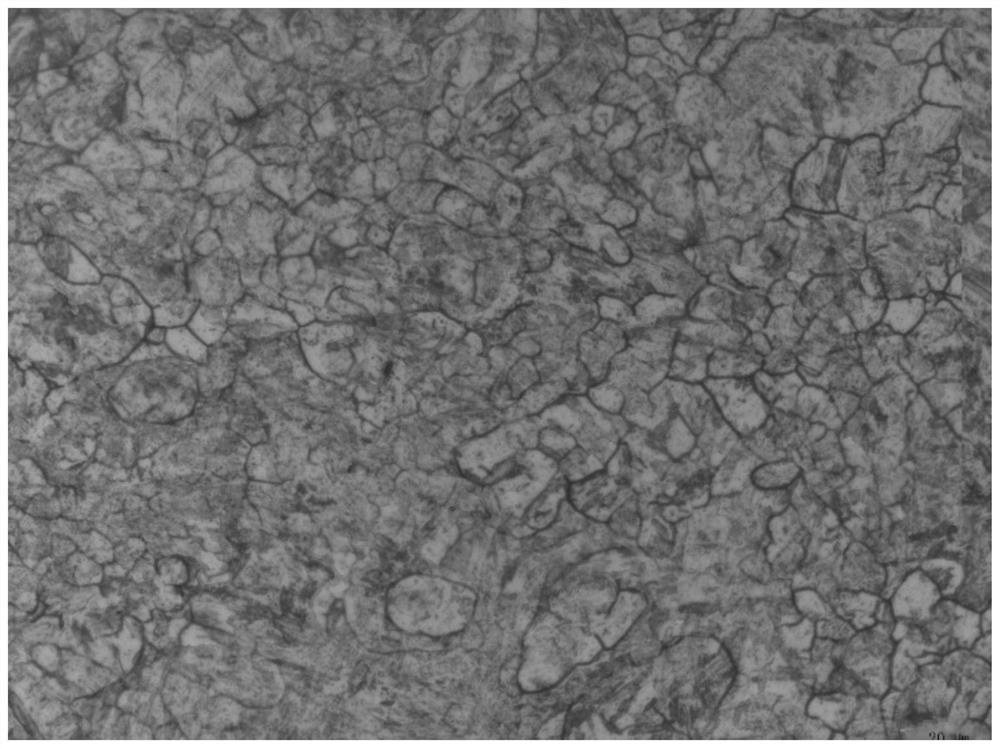

[0036] A method for corrosion of prior austenite grain boundaries of martensitic stainless steel for steam turbine bolts, comprising the following steps:

[0037] (1) Preparation of metallographic samples: martensitic stainless steel for 2Cr11Mo1NiWVNbN steam turbine bolts was oil-quenched at 970°C for 30 minutes, and then oil-quenched. Grind from coarse to fine on 400#, 600#, 800#, 1000#, 1200# sandpaper. After grinding, use W3.5, W1.5, W0.5 diamond polishing paste to polish the sample. Then put it into an ultrasonic cleaning machine for cleaning and dry it with a hair dryer to obtain a metallographic sample with a bright and scratch-free testing surface;

[0038] (2) Preparation of metallographic etchant: first add distilled water to the beaker, then weigh potassium permanganate at a ratio of 1.8-2g per 100mL of distilled water, add it to the beaker and stir until the potassium permanganate is fully dissolved, then add Distilled water is added to the ratio of 6-8mL concentr...

Embodiment 2

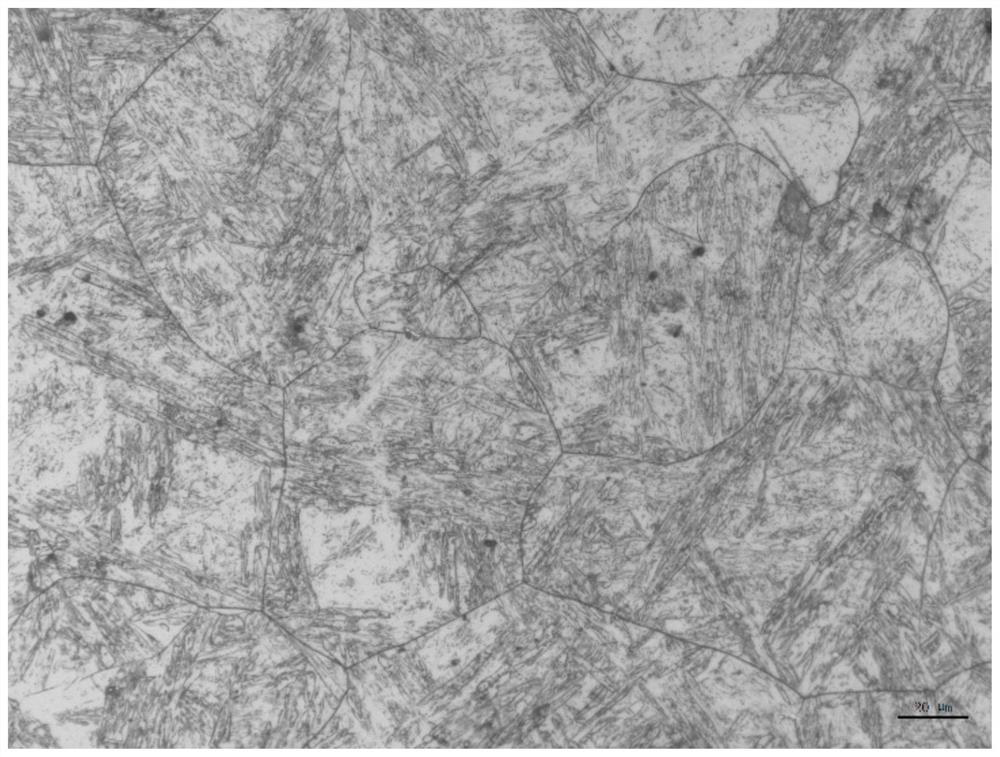

[0044] A method for corrosion of prior austenite grain boundaries of martensitic stainless steel for steam turbine bolts, comprising the following steps:

[0045] (1) Preparation of metallographic samples: martensitic stainless steel for 2Cr11Mo1NiWVNbN steam turbine bolts is oil-quenched at 1070°C for 30 minutes and then oil-quenched. The detection surface of the oil-quenched 2Cr11Mo1NiWVNbN metallographic samples is sequentially placed on 180#, 200#, Grind from coarse to fine on 400#, 600#, 800#, 1000#, 1200# sandpaper. After grinding, use W3.5, W1.5, W0.5 diamond polishing paste to polish the sample. Then put it into an ultrasonic cleaning machine for cleaning and dry it with a hair dryer to obtain a metallographic sample with a bright and scratch-free testing surface;

[0046] (2) Preparation of metallographic etchant: first add distilled water to the beaker, then weigh potassium permanganate at a ratio of 1.8-2g per 100mL of distilled water, add it to the beaker and stir ...

Embodiment 3

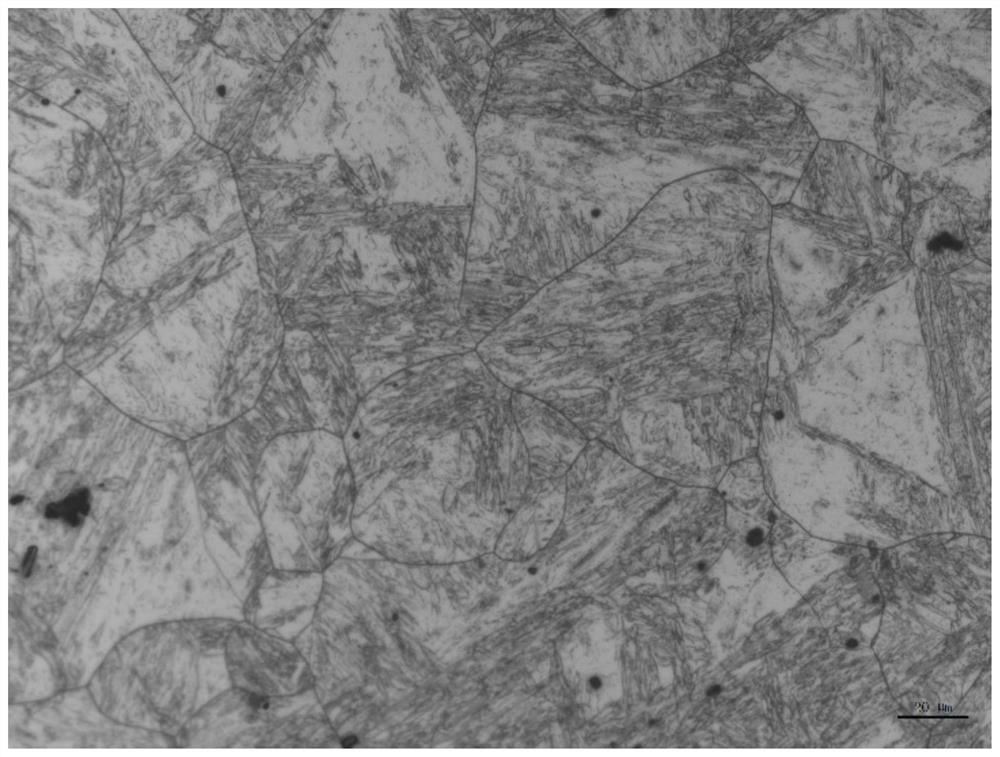

[0052] A method for corrosion of prior austenite grain boundaries of martensitic stainless steel for steam turbine bolts, comprising the following steps:

[0053] (1) Preparation of metallographic samples: martensitic stainless steel for 2Cr11Mo1NiWVNbN steam turbine bolts was oil-quenched at 1120°C for 30 minutes, and then oil-quenched. Grind from coarse to fine on 400#, 600#, 800#, 1000#, 1200# sandpaper. After grinding, use W3.5, W1.5, W0.5 diamond polishing paste to polish the sample. Then put it into an ultrasonic cleaning machine for cleaning and dry it with a hair dryer to obtain a metallographic sample with a bright and scratch-free testing surface;

[0054] (2) Preparation of metallographic etchant: first add distilled water to the beaker, then weigh potassium permanganate at a ratio of 1.8-2g per 100mL of distilled water, add it to the beaker and stir until the potassium permanganate is fully dissolved, then add Distilled water is added to the ratio of 6-8mL concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com