Film laminate metal sheet, substrate for flexible devices, and substrate for organic el devices

A metal plate and film layer technology, applied in lamination, lamination devices, semiconductor devices, etc., can solve the problems of insufficient performance and high cost, and achieve the effect of excellent productivity and low environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] As a raw material resin of the resin film, pellets of PET as a polyester resin were prepared, and were sufficiently dried under high temperature in vacuum so as not to contain moisture. This was put into a single-screw extruder, and it melt-kneaded at 280 degreeC. Next, foreign substances were removed through a sintered filter with a 25 μm cut, and then discharged from a T-die, cooled and solidified on a casting drum whose surface temperature was controlled to 25° C., and an unstretched film was obtained. Next, using the heated ceramic roll, it preheated so that the resin film temperature might become 100 degreeC, and stretched 3.8 times in the longitudinal direction of the resin film. Then, the ends were clamped by chucks, introduced into a tenter stretching machine, and stretched 4.5 times in the transverse direction at 120°C. In this state, 1.0% relaxation was given in the lateral direction while heat-fixing at 165°C. Then, it cooled gradually to room temperature, ...

Embodiment 2

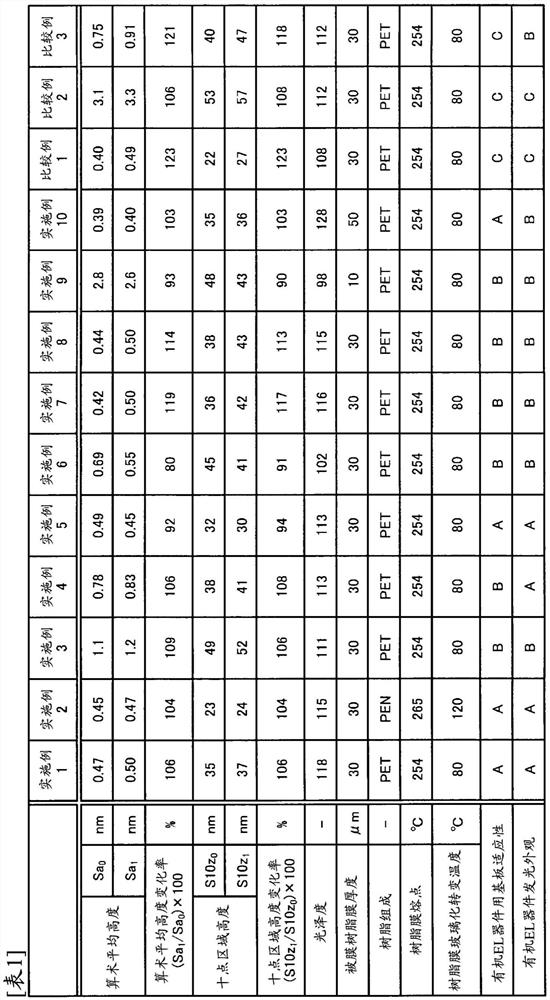

[0080] The polyester resin is PEN, the stretching temperature in longitudinal stretching is 140°C, the stretching temperature in transverse stretching is 150°C, the heat setting temperature is 190°C, and the A film-laminated metal sheet was obtained in the same manner as in Example 1 except that the previous metal sheet temperature was 250°C. The physical properties of the obtained film-laminated metal sheet are shown in Table 1 below.

Embodiment 3

[0082] A film-laminated metal sheet was obtained in the same manner as in Example 1 except that the temperature of the lamination cooling roll was set at 25°C. The physical properties of the obtained film-laminated metal sheet are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com