Automatic treatment system and method for H2S waste gas

A waste gas and automatic valve technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high treatment cost, low degree of automation, and high labor intensity, so as to reduce the consumption of liquid caustic soda and reduce treatment cost, to achieve the effect of automatic unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

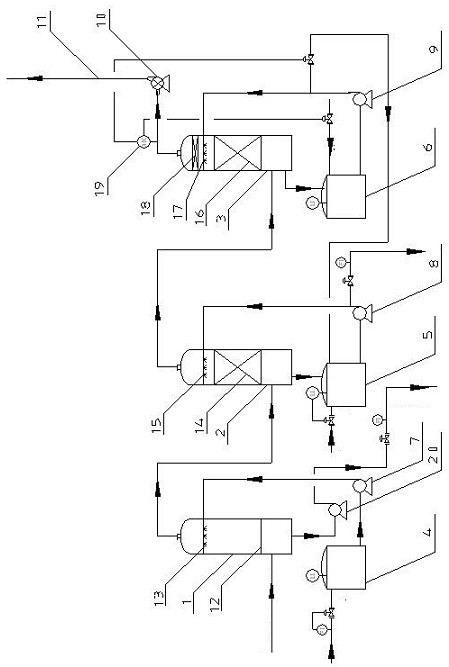

Embodiment 1

[0038] the above H 2 The automatic treatment device and method of S exhaust gas are applied to a certain system, working conditions: exhaust gas volume 3000Nm 3 / h, H 2 The concentration of S is 200-500ppm, and the specific steps are: add 10% sodium sulfide solution through the automatic valve in the sodium sulfide circulation tank 5, close the automatic valve and start the sodium sulfide circulation pump 8 after the liquid level of the sodium sulfide circulation tank reaches 2m; 6. Add 10% lye through the automatic valve, and close the automatic valve to start the liquid-alkali circulation pump at a liquid level of 2m in the liquid-alkali circulation tank; 3 The flow rate of / h enters the acid water circulation tank 4, and the liquid level reaches 1.5m to start the acid water circulation pump 7, and adjust the acid water delivery pump 20 outlet flow to 30m 3 / h, stabilize the liquid level of the acid water circulation tank 4 at about 1.5m; open the induced draft fan 10 to r...

Embodiment 2

[0040] With embodiment 1, above-mentioned H 2 The automatic treatment device and method of S waste gas are applied to another H 2 System with high S concentration, working conditions: exhaust gas volume 7000 Nm 3 / h, H 2 The concentration of S is 600-900ppm, and the specific steps are: add 15% sodium sulfide solution through the automatic valve in the sodium sulfide circulation tank 5, close the automatic valve and start the sodium sulfide circulation pump 8 after the liquid level of the sodium sulfide circulation tank reaches 2m; 6. Add 15% lye through the automatic valve, and close the automatic valve to start the liquid-alkali circulation pump at a liquid level of 2m in the liquid-alkali circulation tank; 3 The flow rate of / h enters the acid water circulation tank 4, and the liquid level reaches 1.5m to start the acid water circulation pump 7, and adjust the acid water delivery pump 20 outlet flow to 50m 3 / h, stabilize the liquid level of the acid water circulation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com