Nonferrous smelting flue gas adiabatic evaporation cooling acid washing arsenic removal purification system and method

A technology for adiabatic evaporation and smelting flue gas, which is applied to chemical instruments and methods, separation methods, waste heat treatment, etc., can solve the problems of cumbersome arsenic removal process and high operating costs, reduce water vapor content, increase dew point temperature, and avoid water volume The effect of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

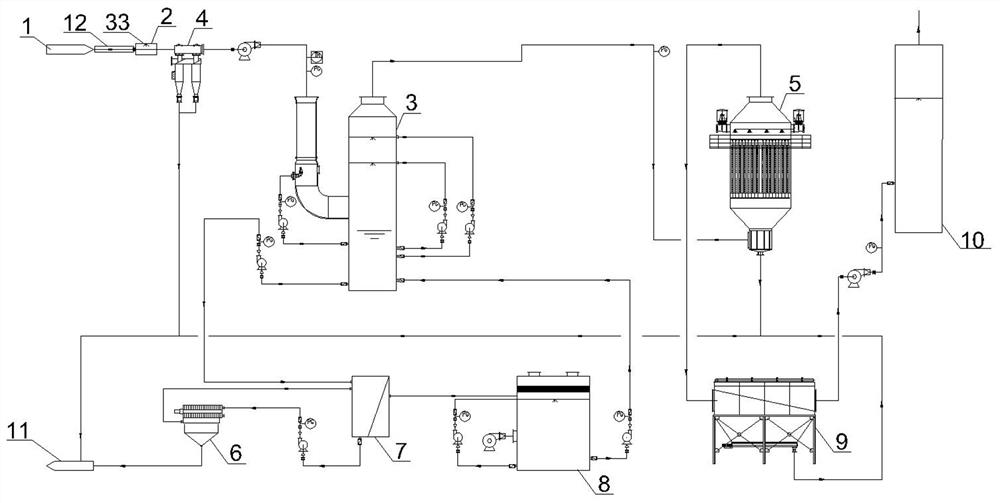

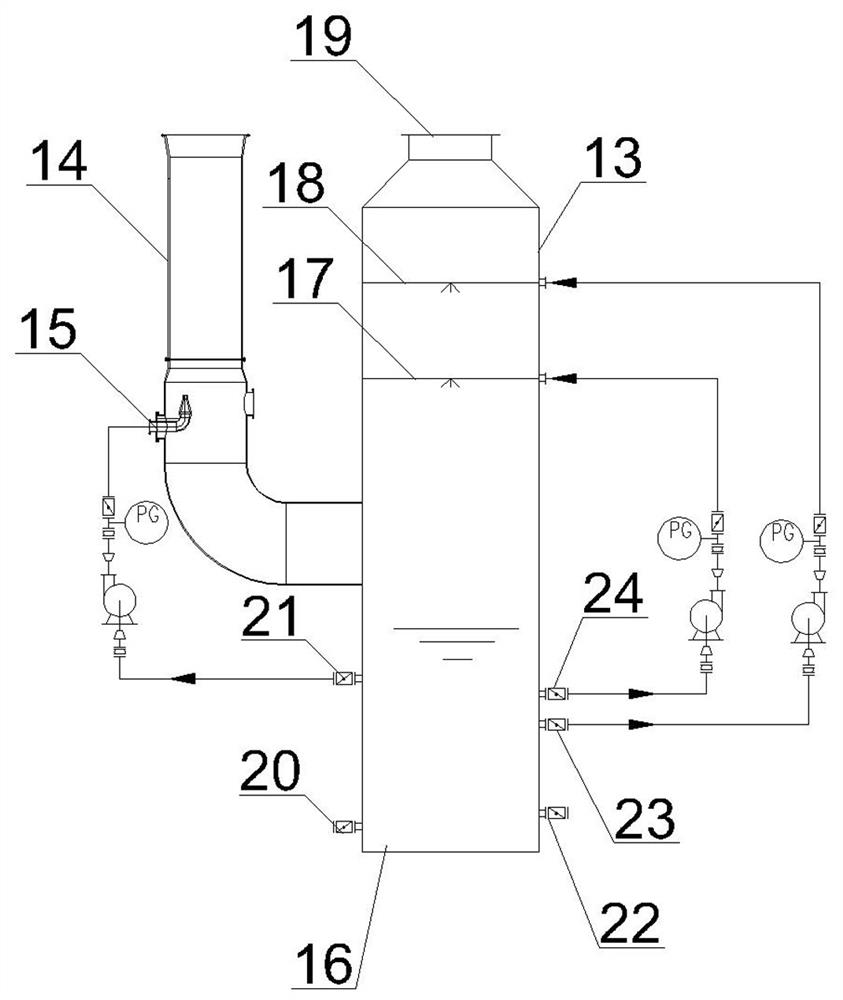

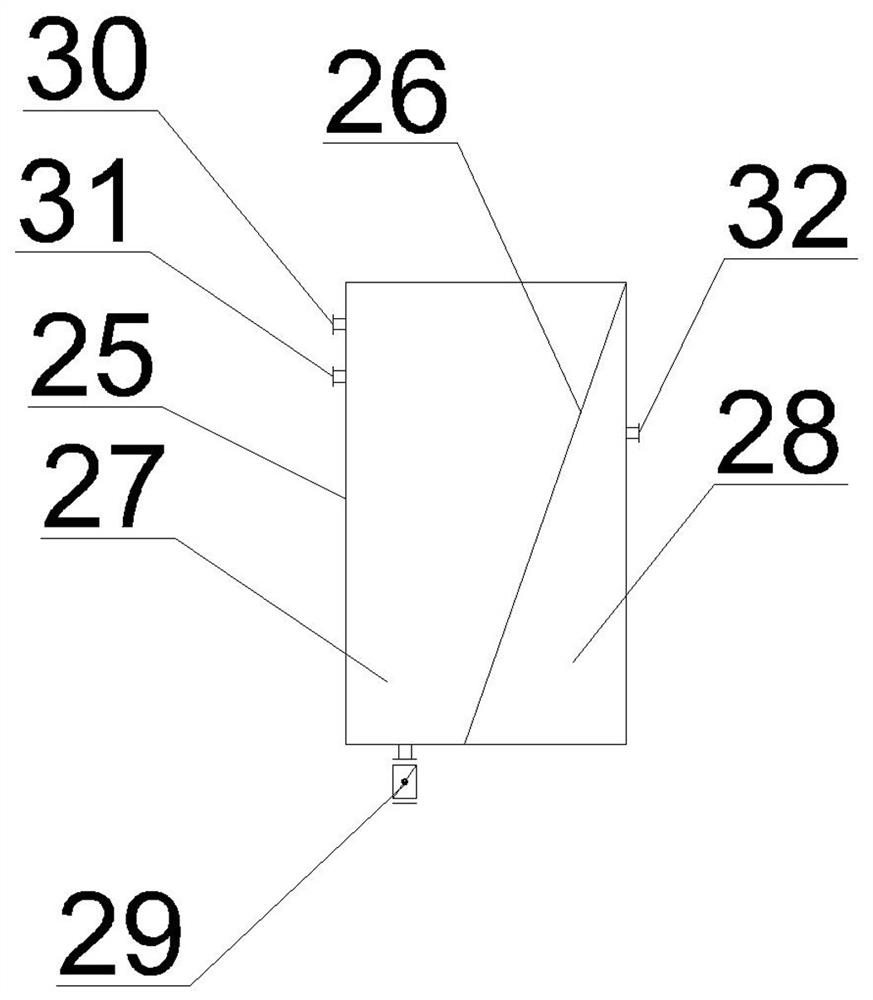

[0030] Embodiment: According to the attached figure 1 , attached figure 2 And attached image 3 For further explanation, a non-ferrous smelting flue gas adiabatic evaporative cooling acid washing and arsenic removal purification system and its method in this example include a factory 1, an adiabatic evaporator 2, an acid spray tower 3, a rotary dust collector 4, and a mist eliminator 5. Plate and frame filter press 6, inclined plate sedimentation separator 7, liquid heat exchanger 8, plastic burnt plate dust collector 9, water spray tower 10 and waste collection tank 11, the exhaust end of the factory 1 is connected to the A carbon steel flue 12 is provided between the inlet ends of the adiabatic evaporator 2, the outlet end of the adiabatic evaporator 2 is connected to the inlet end of the rotary dust collector 4, and the waste end of the rotary dust collector 4 is connected to the waste material The feed end of the collection tank 11 is connected by a pipeline, the gas ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com