Preparation method and application of a functionalized magnetic adsorption material

A magnetic adsorption material and functionalization technology, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., can solve problems such as difficult separation and limited application, and achieve large adsorption capacity, high adsorption capacity and selectivity, removal high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

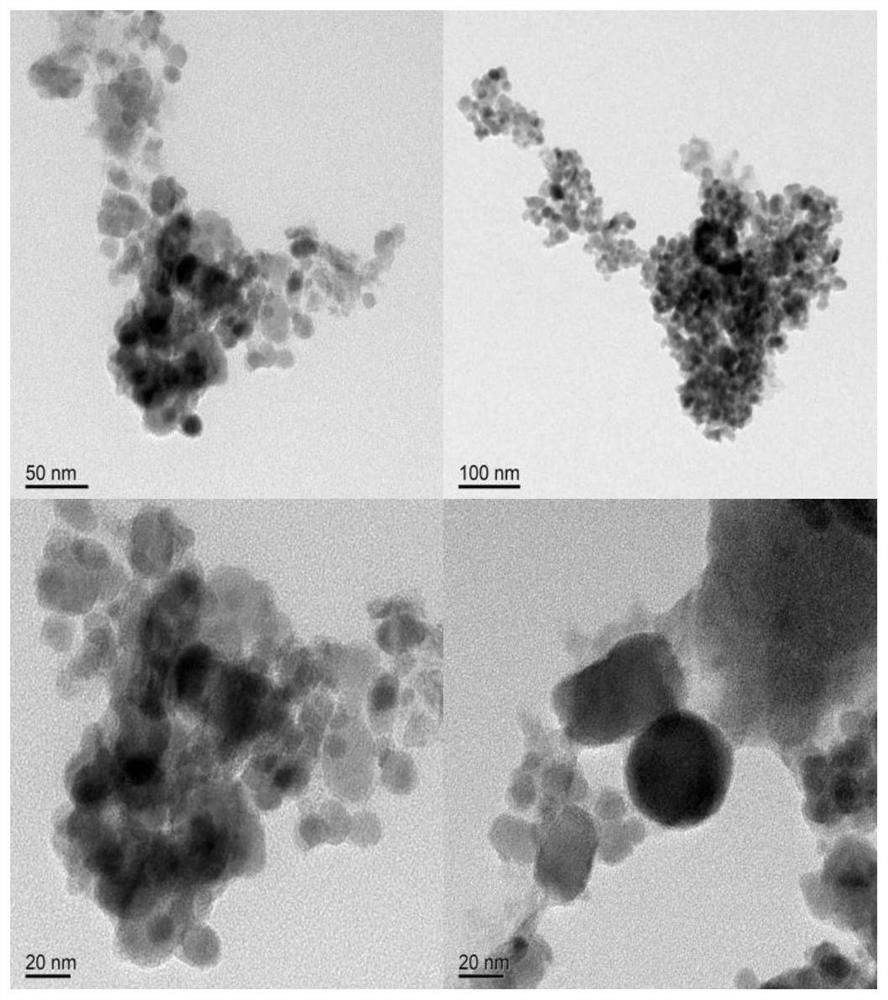

[0040] A preparation method of functionalized magnetic adsorption material, the steps are:

[0041] a. Add 0.01 mol 2,5-dihydroxy-1,4-benzenediphosphonic acid ethyl ester to 25 mL solvent A toluene (dissolve), add 0.005 mol nano-ferric oxide (powder), at a temperature of 80°C Under the condition of magnetic stirring reaction for 10 hours, obtain the material after reaction;

[0042] b. Cool the reacted material, filter and separate (can be separated by centrifugation or magnetic separation), wash the solid with solvent B (centrifugal wash 10 times with ethyl acetate), and dry to obtain a functionalized magnetic adsorption material (i.e. phosphoric acid Ester-functionalized nano-Fe3O4 particle adsorption material).

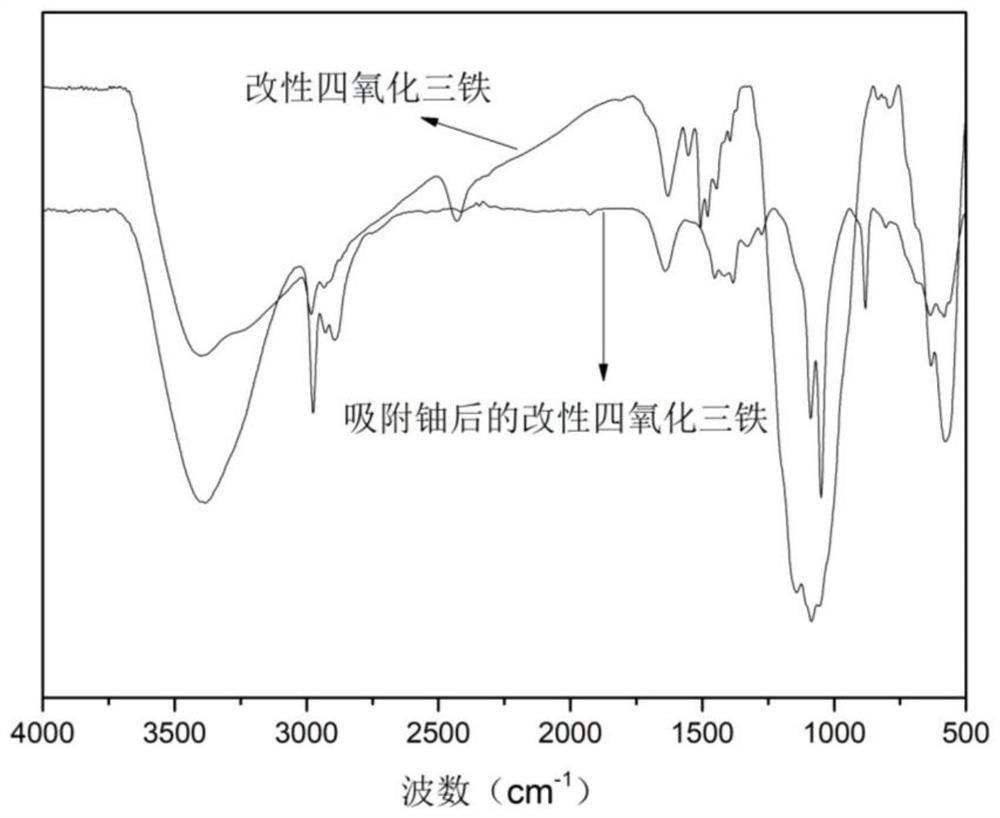

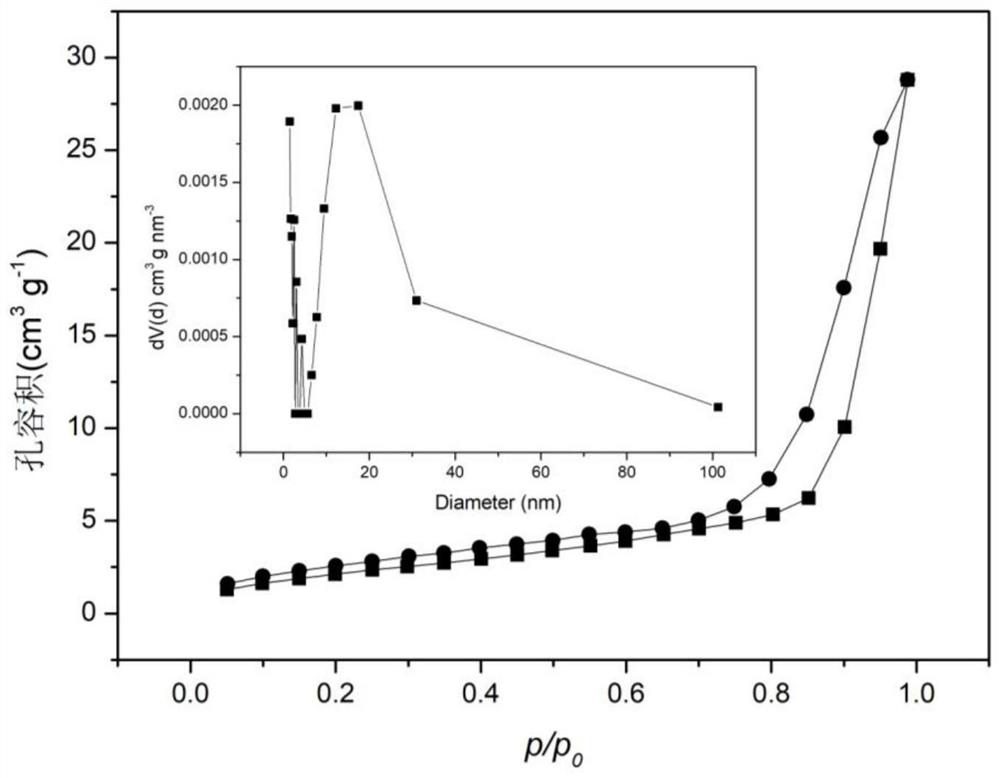

[0043] Performance Testing:

[0044](1) Take the functionalized magnetic adsorption material prepared in Example 1 and add it to a pre-configured concentration of 50 mg L -1 and a uranyl ion solution with a pH of 5, placed in a gyratory shaker at 30°C for 10 hou...

Embodiment 2

[0047] A preparation method of functionalized magnetic adsorption material, the steps are:

[0048] a. Add 0.01 mol ethyl 2,5-dihydroxy-1,4-benzenediphosphonate and 0.01 mol diethyl 2,5-dihydroxyphenylphosphonate to 60 mL of solvent A N,N-dimethylmethane Add 0.01 mol nano iron ferric oxide (powder) to the amide (dissolved), and react at a temperature of 30°C for 5 hours to obtain the reacted material;

[0049] b. After the reaction, the material is cooled, filtered and separated (by centrifugation or magnetic separation), and the solid is washed with solvent B ethanol (centrifugal washing 5 times) and dried to obtain a functionalized magnetic adsorption material (that is, a phosphate functionalized nanometer ferric oxide particle adsorption material).

[0050] Performance Testing:

[0051] Get the functionalized magnetic adsorption material prepared in Example 2, add it to a pre-configured concentration of 50 mg L -1 and a uranyl ion solution with a pH of 2-8, placed in a g...

Embodiment 3

[0053] A preparation method of functionalized magnetic adsorption material, the steps are:

[0054] a. Add 0.01mol diethyl 2,5-dihydroxyphenylphosphonate into 30ml solvent A pentane (dissolve), add 0.01mol nanometer ferric oxide (powder), under the condition of 120℃ Reacted for 15 hours to obtain the reacted material;

[0055] b. After the reaction, the material is cooled, filtered and separated (by centrifugation or magnetic separation), and the solid is washed with solvent B (centrifugal washing with ethyl acetate for 5 times, and then with water for 5 times), and then dried to obtain the function Magnetic adsorption material (that is, phosphate functionalized nano ferric oxide particle adsorption material).

[0056] Performance Testing:

[0057] 20 mg L at pH 5 in 1000 mL -1 Add 50 mg of the functionalized magnetic adsorption material (or phosphate-functionalized nanometer ferric oxide particle adsorption material) prepared in Example 3 to the uranyl ion solution, and sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com