Environment-friendly efficient cleaning agent and preparation method thereof

A cleaning agent and environment-friendly technology, applied in the field of environment-friendly high-efficiency cleaning agent and its preparation, can solve the problems of unsatisfactory cleaning effect, inability to print mechanical protective effect, and no corrosion inhibition performance, so as to inhibit the growth of bacteria, Good surface activity and wetting performance, the effect of improving the printing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

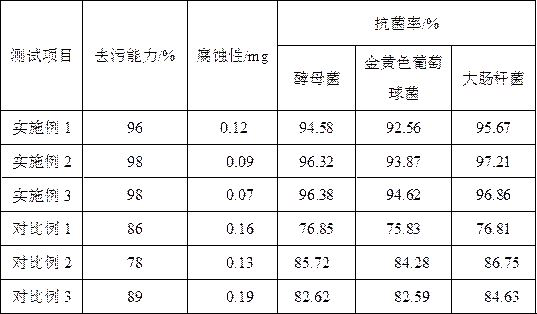

Examples

Embodiment 1

[0028] An environment-friendly high-efficiency cleaning agent, the cleaning agent is composed of the following components in parts by weight: 90 parts of magnetically activated water, 12 parts of D-limonene, 6 parts of sodium oleate soap, 3 parts of compound surfactant, 5 parts of auxiliary cleaning agent , 3 parts of fatty alcohol polyoxyethylene ether, 2.0 parts of triethanolamine, 1.8 parts of sodium silicate, 2.5 parts of simethicone and 3 parts of Sophora flavescens essential oil.

[0029] The compound surfactant consists of diethanolamine, polyoxyethylene sorbitan laurate and diacetylethylenediamine bis[dimethyl oleic acid amidopropyl ammonium bromide] in a mass ratio of 1:0.8:2 Prepared by mixing.

[0030] The preparation method of auxiliary cleaning agent comprises the following steps:

[0031] Ⅰ. Dry, pulverize and grind an appropriate amount of cleaned loofah and purslane, and soak the mixed powder with a particle size of 100 mesh in an appropriate amount of clear w...

Embodiment 2

[0042] The environment-friendly high-efficiency cleaning agent provided in this embodiment and its preparation method are roughly the same as in Example 1, the main difference being that the cleaning agent is composed of the following parts by weight: 95 parts of magnetically activated water, 15 parts of D-limonene, 8 Parts of sodium oleate soap, 4 parts of compound surfactant, 6 parts of auxiliary cleaning agent, 4 parts of fatty alcohol polyoxyethylene ether, 3 parts of triethanolamine, 2 parts of sodium silicate, 3 parts of simethicone and 5 parts of bitter Ginseng essential oil.

[0043] The compound surfactant consists of diethanolamine, polyoxyethylene sorbitan laurate and diacetylethylenediamine bis[dimethyl oleic acid amidopropyl ammonium bromide] in a mass ratio of 1:1:4 Prepared by mixing.

[0044] The preparation method of auxiliary cleaning agent comprises the following steps:

[0045] Ⅰ. Dry, pulverize and grind an appropriate amount of cleaned loofah and pursla...

Embodiment 3

[0054] The environment-friendly high-efficiency cleaning agent provided in this embodiment and its preparation method are roughly the same as in Example 1, the main difference being that the cleaning agent consists of the following parts by weight: 100 parts of magnetically activated water, 18 parts of D-limonene, 10 parts of D-limonene, Parts of sodium oleate soap, 5 parts of compound surfactant, 8 parts of auxiliary cleaning agent, 6 parts of fatty alcohol polyoxyethylene ether, 4.0 parts of triethanolamine, 2.5 parts of sodium silicate, 3.2 parts of simethicone and 6 parts of bitter Ginseng essential oil.

[0055] The compound surfactant consists of diethanolamine, polyoxyethylene sorbitan laurate and diacetylethylenediamine bis[dimethyl oleic acid amidopropyl ammonium bromide] in a mass ratio of 1:1.2:8 Prepared by mixing.

[0056] The preparation method of auxiliary cleaning agent comprises the following steps:

[0057] Ⅰ. Dry, pulverize and grind an appropriate amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com