A kind of oil dirt cleaning agent and preparation method

A cleaning agent and dirt technology, applied in the direction of chemical instruments and methods, surface active non-soap compounds and cleaning compositions, detergent compositions, etc., can solve the problem that the lotion cannot be reused, the oil content is unlimited, and the cleaning object is single and other problems, to achieve excellent cleaning effect, reduce oil-water interfacial tension, and achieve the effect of large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

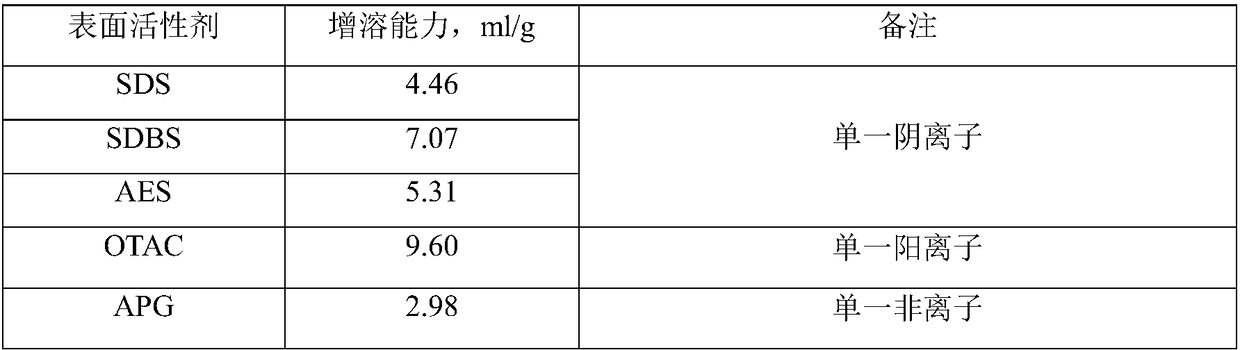

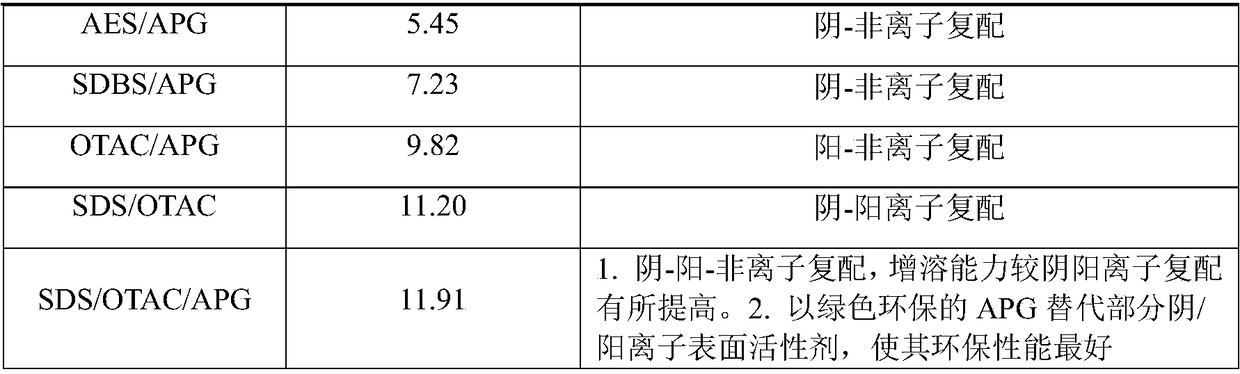

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Use n-octane as the oil phase, cleaning solution for metal

[0035] The oil stain used in this example is a viscous bio-oil, which is attached to the surface of the aluminum sheet, deposited for more than 24 hours, and cleaned with the cleaning agent of the present invention, and the cleaning when the viscous oil stain is attached to the surface of the metal material is investigated. Effect.

[0036] (1) Oil sample preparation

[0037] Cut a piece about 3×3cm 2 Aluminum sheets of different sizes were washed, dried and weighed. Apply bio-oil, which is liquid at room temperature, on No. 1 aluminum sheet, dry it in an oven (100°C), and weigh it; calculate the oil content (η) of the aluminum sheet, see formula (1).

[0038]

[0039] Among them, m o Indicates the mass of the washed and dried aluminum sheet, g; m 1 Indicates the mass of oily aluminum sheet before cleaning, g. The calculated oil content (η) of the aluminum sheet is 3.5 wt%.

[0040] (2)...

Embodiment 2

[0051] Embodiment 2: Take n-octane as the oil phase, cleaning solution for metal

[0052] The oil stain used in this example is a highly viscous decompression residue, which is attached to the surface of the aluminum sheet, deposited for more than 24 hours, and cleaned with the cleaning agent of the present invention. cleaning effect.

[0053] (1) Oil sample preparation

[0054] The method described in Example 1 was used to prepare an oil-stained aluminum sheet with a vacuum residue content of 13.2%.

[0055] (2) Preparation of cleaning agent

[0056] 1) Weigh 15.00 g of n-octane and 6.15 g of water, and put them into a glass container;

[0057] 2) Weigh 1.50 g of sodium dodecyl sulfate (SDS), 1.50 g of octadecyltrimethylammonium chloride (OTAC), and 1.50 g of decyl glucoside, mix them uniformly, add them to the above container, and shake them fully;

[0058] 3) Weigh 3.60g of n-butanol, 0.15 pieces of sodium chloride, 0.15g of builder-sodium tripolyphosphate, and 0.3g of ...

Embodiment 3

[0062] Embodiment 3: Use n-octane as the oil phase, cleaning solution for metal

[0063] The oil stain used in this embodiment is a relatively viscous atmospheric residue, which is attached to the surface of the aluminum sheet, deposited for more than 24 hours, and cleaned with the cleaning agent of the present invention. cleaning effect.

[0064] (2) Oil sample preparation

[0065] The method described in Example 1 was used to prepare an oil-stained aluminum sheet with an atmospheric residue content of 14.3%.

[0066] (2) Preparation of cleaning agent

[0067] 1) Weigh 12.00 g of n-octane and 12.38 g of water, and put them into a glass container;

[0068] 2) Weigh 0.90 g of sodium dodecyl sulfate (SDS), 0.90 g of octadecyltrimethylammonium chloride (OTAC), and 0.60 g of decyl glucoside, mix them uniformly, add them to the above container, and shake them fully;

[0069] 3) Weigh 3.00g of n-butanol, 0.05g of sodium chloride, 0.09g of builder-sodium tripolyphosphate, and 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com