Titanium-nickel shape memory alloy target material and preparation method thereof

A memory alloy, titanium-nickel technology, applied in the field of shape memory alloy target preparation, can solve the problems of complex operation, poor effect, high processing cost, etc., and achieve the effect of high target purity, lower temperature, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An embodiment of a titanium-nickel shape memory alloy target of the present invention is as follows:

[0037] (1) Add metal titanium and metal nickel into the crucible of the magnetic levitation melting furnace in an alternate tiled manner, vacuumize the magnetic levitation melting furnace, fill the furnace with argon gas, and then fill the furnace with new argon gas after vacuuming again The air pressure is 2.0×10 -2 Pa, then heat the temperature to 1350°C for 6 minutes, and smelt for 6 minutes to obtain an alloy melt; the mass ratio of the metal titanium to the metal nickel is 4:6;

[0038] (2) Cast the alloy body into a water-cooled carbon steel mold within 10s, and pass cooling water at 10°C through the water-cooled carbon steel mold to cool the alloy melt from bottom to top for 2 hours to obtain a target blank;

[0039] (3) Machining the target blank to obtain the titanium-nickel shape memory alloy target.

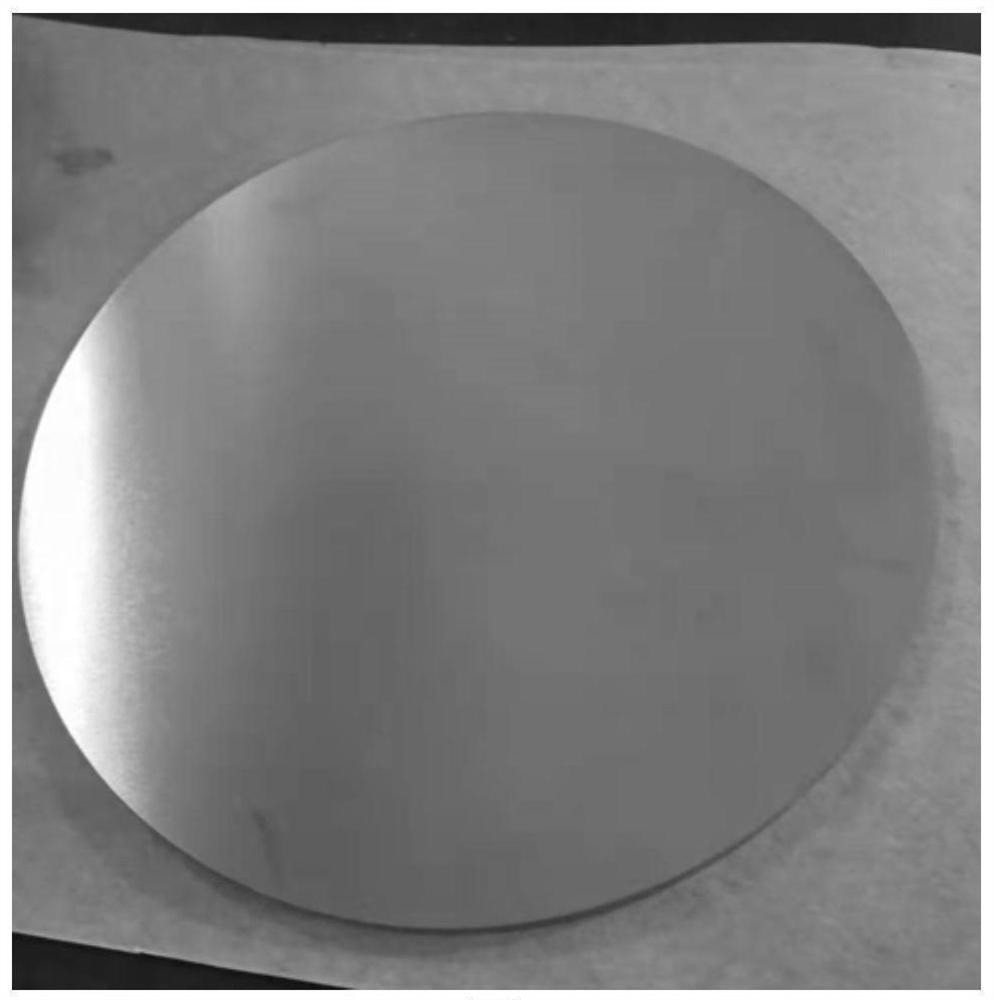

[0040] figure 1 with figure 2 It is an appearance vi...

Embodiment 2

[0044] An embodiment of a titanium-nickel shape memory alloy target of the present invention is as follows:

[0045] (1) Add metal titanium and metal nickel into the crucible of the magnetic levitation melting furnace in an alternate tiled manner, vacuumize the magnetic levitation melting furnace, fill the furnace with argon gas, and then fill the furnace with new argon gas after vacuuming again The air pressure is 2.0×10 -2 Pa, heat the temperature to 1360°C in 7 minutes, and smelt for 8 minutes to obtain an alloy melt; the mass ratio of the metal titanium to the metal nickel is 4:6;

[0046] (2) Cast the alloy body into a water-cooled carbon steel mold within 10s, and pass cooling water at 10°C through the water-cooled carbon steel mold to cool the alloy melt from bottom to top for 2 hours to obtain a target blank;

[0047] (3) Machining the target blank to obtain the titanium-nickel shape memory alloy target.

[0048] The titanium-nickel shape memory alloy target prepared...

Embodiment 3

[0050]An embodiment of a titanium-nickel shape memory alloy target of the present invention is as follows:

[0051] (1) Add metal titanium and metal nickel into the crucible of the magnetic levitation melting furnace in an alternate tiled manner, vacuumize the magnetic levitation melting furnace, fill the furnace with argon gas, and then fill the furnace with new argon gas after vacuuming again The air pressure is 2.0×10 -2 Pa, heat the temperature to 1350°C for 6 minutes and melt for 4 minutes to obtain an alloy melt; the mass ratio of the metal titanium to the metal nickel is 4:6;

[0052] (2) Cast the alloy body into a water-cooled carbon steel mold within 10s, and pass cooling water at 10°C through the water-cooled carbon steel mold to cool the alloy melt from bottom to top for 2 hours to obtain a target blank;

[0053] (3) Machining the target blank to obtain the titanium-nickel shape memory alloy target.

[0054] The titanium-nickel shape memory alloy target prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com