Method for removing carbon deposits of aircraft turbine blade through electrolysis

A technology for aircraft turbine blades and turbine blades, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of simple process methods, reduced surface roughness, and reduced carbon deposition on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

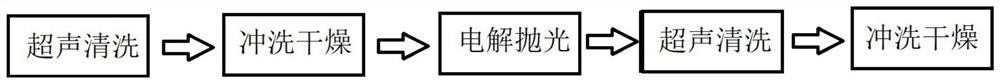

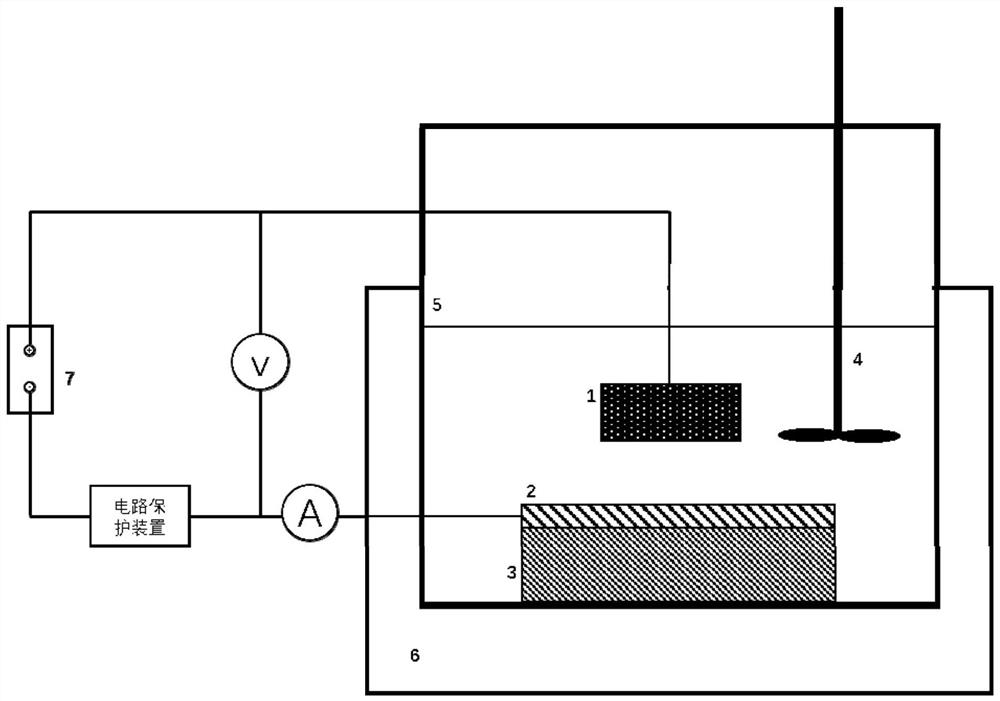

[0037] The invention provides a cleaning method for aircraft engine turbine blades, which combines the existing ultrasonic cleaning method with electrolytic polishing technology, and adopts any ultrasonic cleaning equipment available in the market. The electrolytic polishing equipment may be any one of slot-type electrolytic polishing equipment and brush-type electrolytic polishing equipment. The specific cleaning steps are as follows:

[0038] ①Put the turbine blade workpiece into the ultrasonic cleaning equipment, and let the cleaning agent submerge the turbine blade. The cleaning liquid in the ultrasonic cleaning equipment can be water-based metal cleaning agent, semi-water-based metal cleaning agent, and solvent-based metal cleaning agent. Any one, the cleaning temperature is any temperature between 30°C and 50°C, and the cleaning time is between 30min and 1h. The cleaning effect reaches the level where the remaining carbon deposits cannot be removed by ultrasonic cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com