Multi-layer phase-change energy-saving wallboard with good heat preservation effect and assembly method thereof

A wallboard and phase change technology, applied in heat preservation, wall, building material treatment, etc., can solve the problems of incombustible fire prevention, low hardness, poor heat preservation effect, etc., to achieve convenient and direct closed installation, high stability and structure high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] The present invention provides a technical solution: the assembly steps include the following,

[0033] S1, pretreatment: Prepare preformed wall panels 11, lightweight concrete wall panels 12 and phenolic composite insulation panels 13, and three-layer wall panels are compositely compressed and fixed;

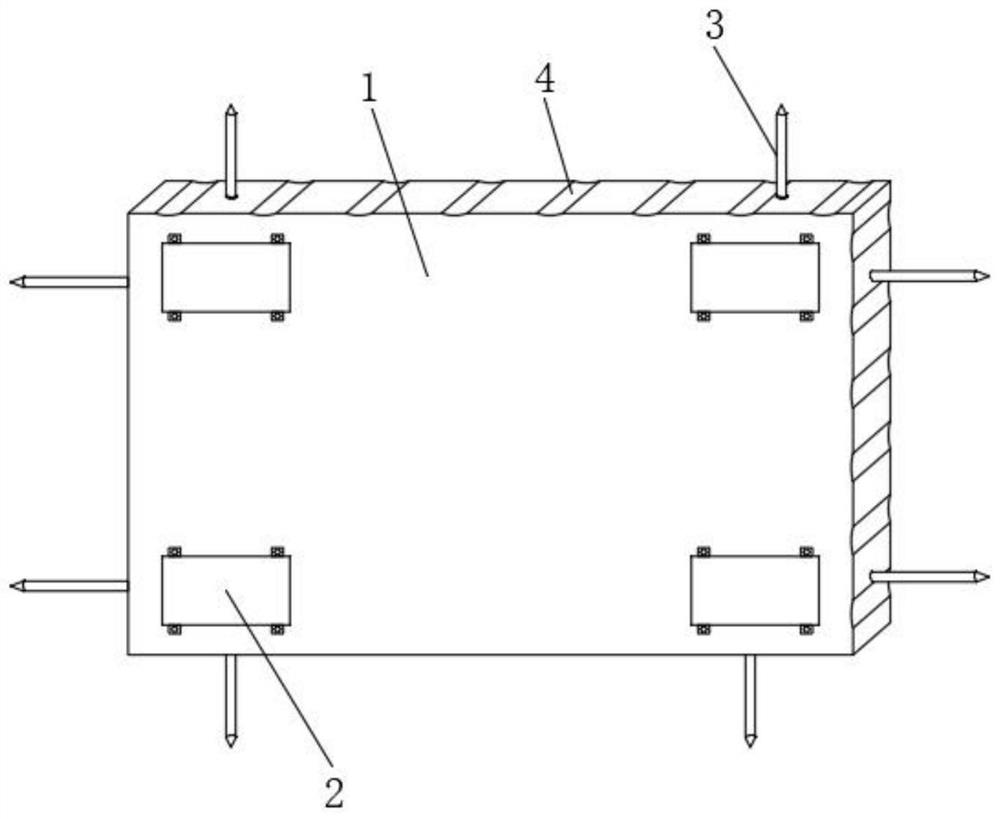

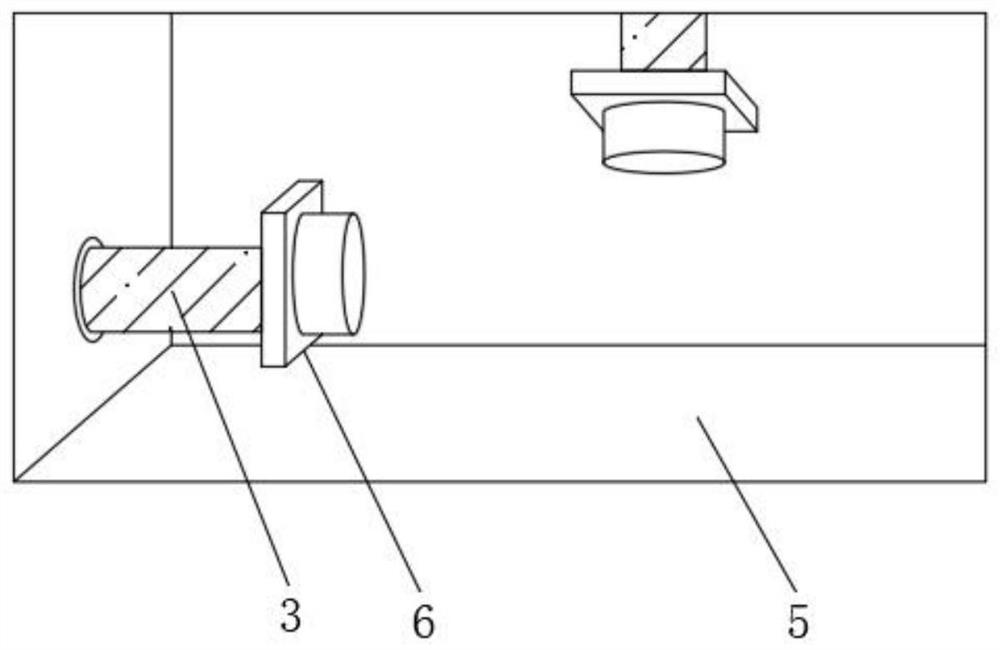

[0034] S2, install the anchor rod: open the installation groove 5 at the front corner of the energy-saving wall panel body 1, and use the through hole of the anchor rod 3 to penetrate the inner wall of the installation groove 5 for high-strength positioning installation;

[0035] S3, gluing and fixing: use structural glue to coat the outer edge of the energy-saving wall panel body 1, fill the groove 4 evenly, and install the energy-saving wall panel body 1 in a sealed and stable position;

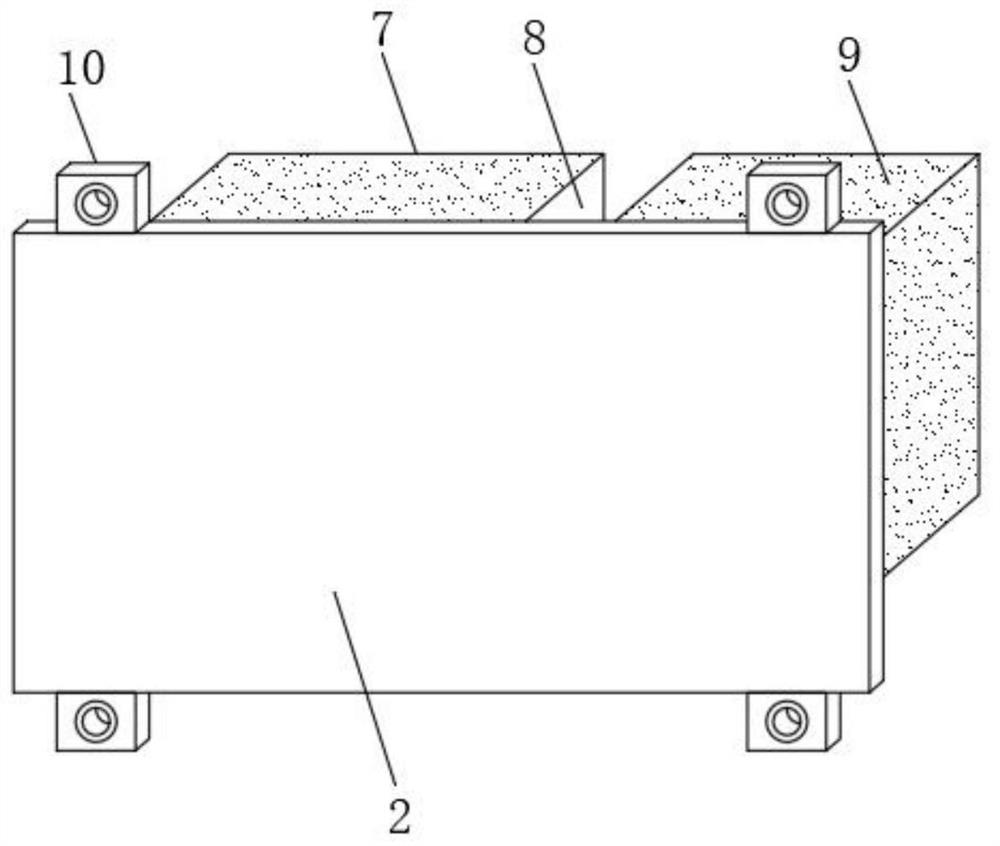

[0036] S4, Embedded sealing installation: use the positioning closing plate 2 and the inlaying plate 7 to be embedded and installed in the installation groove 5, and be sealed and tig...

example 2

[0039] The present invention provides a technical solution: the assembly steps include the following,

[0040] S1, pretreatment: Prepare preformed wall panels 11, lightweight concrete wall panels 12 and flame-retardant panels 14, and three-layer wall panels are compositely compressed and fixed;

[0041] S2, install the anchor rod: open the installation groove 5 at the front corner of the energy-saving wall panel body 1, and use the through hole of the anchor rod 3 to penetrate the inner wall of the installation groove 5 for high-strength positioning installation;

[0042] S3, gluing and fixing: use structural glue to coat the outer edge of the energy-saving wall panel body 1, fill the groove 4 evenly, and install the energy-saving wall panel body 1 in a sealed and stable position;

[0043] S4, Embedded sealing installation: use the positioning closing plate 2 and the inlaying plate 7 to be embedded and installed in the installation groove 5, and be sealed and tightened by the ...

example 3

[0046] The present invention provides a technical solution: the assembly steps include the following,

[0047] S1, pretreatment: prepare the preformed wallboard 11, lightweight concrete wallboard 12, phenolic composite insulation board 13 and flame-retardant board 14, and the four-layer wallboard is compositely compressed and fixed;

[0048] S2, install the anchor rod: open the installation groove 5 at the front corner of the energy-saving wall panel body 1, and use the through hole of the anchor rod 3 to penetrate the inner wall of the installation groove 5 for high-strength positioning installation;

[0049] S3, gluing and fixing: use structural glue to coat the outer edge of the energy-saving wall panel body 1, fill the groove 4 evenly, and install the energy-saving wall panel body 1 in a sealed and stable position;

[0050] S4, Embedded sealing installation: use the positioning closing plate 2 and the inlaying plate 7 to be embedded and installed in the installation groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com