Gangue brick production system and production process for drying sludge by using waste heat of brick kiln

A production system and sludge drying technology, which is applied in the production process of gangue brick production system and in the field of gangue brick production system, can solve the problems of not fully utilizing energy, affecting the surrounding environment, and resource waste, so as to reduce energy consumption, Reduced operating costs and reduced capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

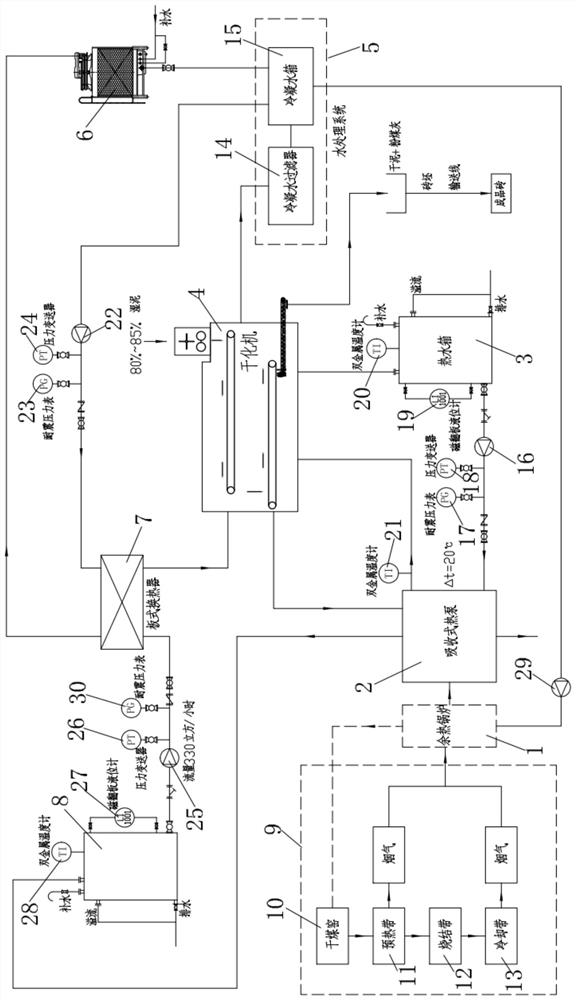

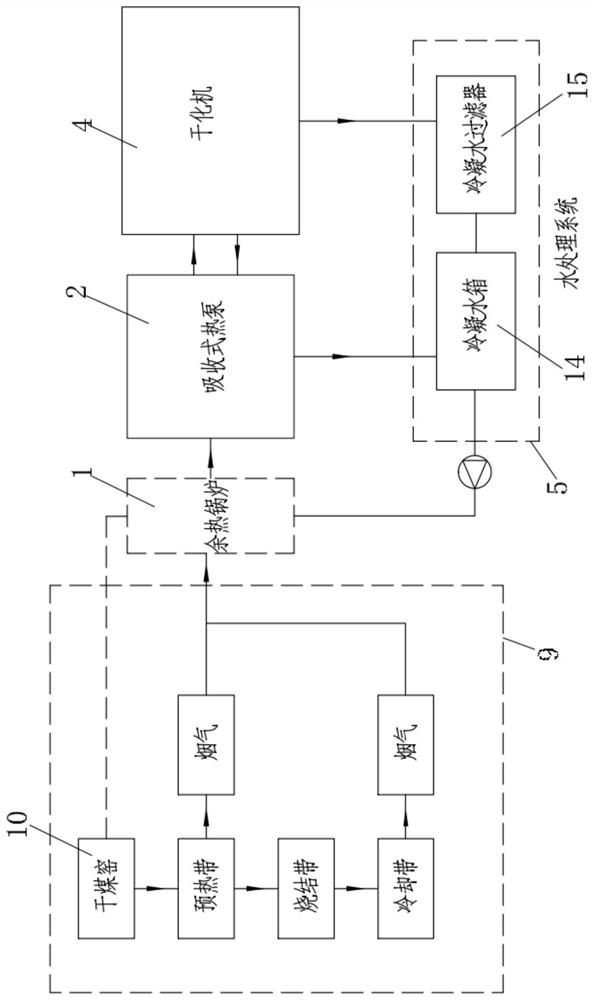

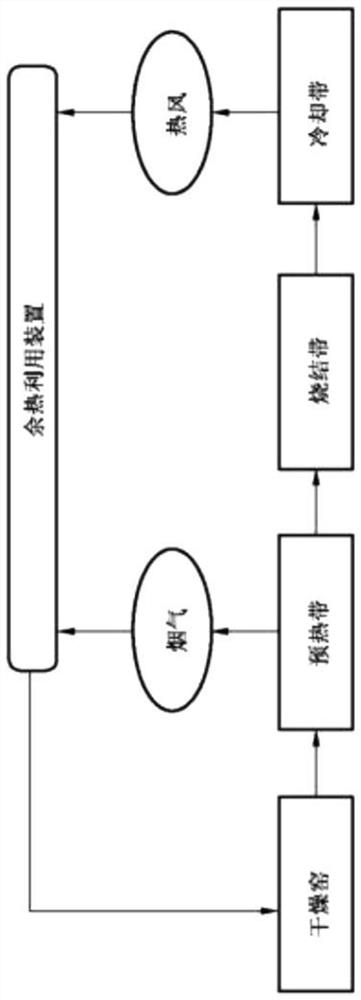

[0039] Such as Figure 1-4 The gangue brick production system that utilizes brick kiln waste heat to dry sludge shown in the figure includes waste heat boiler 1, absorption heat pump 2, hot water tank 3, sludge dryer 4, water treatment device 5, cooling tower 6, plate exchange Heater 7 and cold water tank 8, one end of the waste heat boiler 1 is connected to the brick kiln, and the other end of the waste heat boiler 1 is connected to the absorption heat pump 2, and the absorption heat pump 2 is connected to the hot water tank 3 through the water pump. The hot water tank 3 is connected to the sludge dryer 4, and the sludge dryer 4 is connected to the absorption heat pump 2 and the water treatment device 5, and the water treatment device 5 is connected to the water inlet end of the plate heat exchanger 7 and The cooling towers 6 are all connected, the other water inlet end of the plate heat exchanger 7 is connected to the cold water tank 8, and the water outlet end of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com