Antigen-free collagen aggregate and preparation method thereof

An aggregate and antigen-free technology, which is applied in medical science, surgery, surgical instruments, etc., can solve the problems that the fracture strength of antigen-free collagen aggregates cannot meet the application requirements, the process is complicated, time-consuming and labor-intensive, etc., and achieve optimal fracture strength , Simplify the preparation process and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

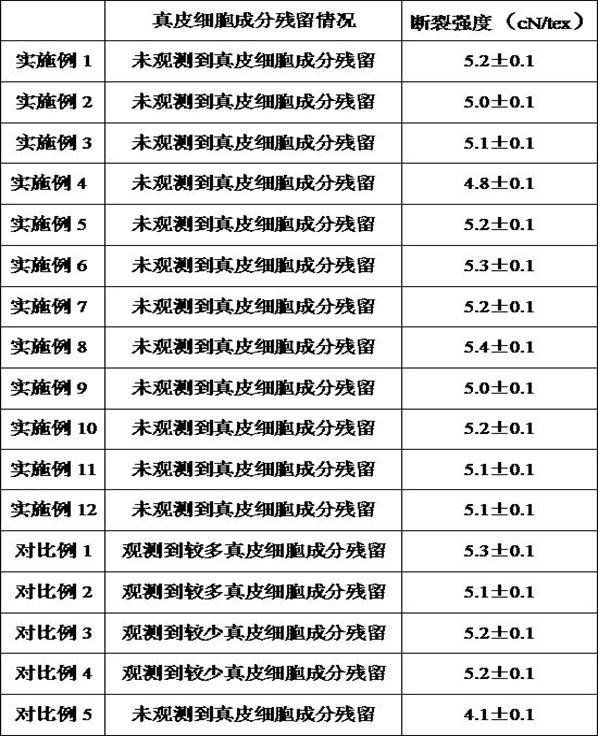

Examples

Embodiment 1

[0045] A) Take fresh and traceable bovine Achilles tendon, remove the muscle, marginal cartilage, blood vessels and fascia tissue on the surface of the bovine Achilles tendon, then cut it into thin slices with a thickness of 0.2 mm, soak it in normal saline for 30 minutes at room temperature, and then use Rinse repeatedly with double distilled water;

[0046] B) Put 10 parts by weight of bovine Achilles tendon slices in a supercritical fluid processor, add 100 parts by weight of toluene and 0.1 parts by weight of polyethylene glycol p-isooctyl phenyl ether, under pressure 10.0Mpa, room temperature Treated under the condition of 1h, after the end, rinse repeatedly with double distilled water until the beef Achilles tendon has no toluene smell to obtain the defatted beef Achilles tendon;

[0047] C) Soak the defatted beef Achilles tendon prepared in step B) in 100 parts by weight of Tris-NaCl (Tris: 0.05mol / L; NaCl: 2mol / L; pH7.5) buffer solution under ultrasonic conditions, St...

Embodiment 2

[0050] A) Take the fresh and traceable sheep Achilles tendon, remove the muscle, marginal cartilage, blood vessels and fascia tissue on the surface of the sheep Achilles tendon, then cut it into thin slices with a thickness of 0.2 mm, soak it in normal saline for 30 minutes at room temperature, and then use Rinse repeatedly with double distilled water;

[0051] B) Put 10 parts by weight of sheep Achilles tendon thin slices in a supercritical fluid processor, add 100 parts by weight of toluene and 0.1 parts by weight of polyethylene glycol p-isooctyl phenyl ether, at a pressure of 10.0Mpa, room temperature After treatment for 1 hour under the condition of 1 hour, rinse repeatedly with double distilled water until the sheep Achilles tendon has no toluene smell, then the degreased sheep Achilles tendon is obtained;

[0052] C) Soak the degreased sheep Achilles tendon prepared in step B) in 100 parts by weight of Tris-NaCl (Tris: 0.05mol / L; NaCl: 2mol / L; pH7.5) buffer solution und...

Embodiment 3

[0055] A) Take a fresh and traceable dog Achilles tendon, remove the muscle, marginal cartilage, blood vessels and fascia tissue on the surface of the dog Achilles tendon, then cut it into thin slices with a thickness of 0.2 mm, soak it in normal saline for 30 minutes at room temperature, and then use Rinse repeatedly with double distilled water;

[0056] B) Put 10 parts by weight of dog Achilles tendon thin slices in a supercritical fluid processor, add 100 parts by weight of toluene and 0.1 parts by weight of polyethylene glycol p-isooctyl phenyl ether, at a pressure of 10.0Mpa, room temperature Treated for 1 hour under the condition of 1 hour, rinsed repeatedly with double distilled water until the dog Achilles tendon has no toluene smell, then the degreased dog Achilles tendon was obtained;

[0057] C) Soak the defatted dog Achilles tendon prepared in step B) in 100 parts by weight of Tris-NaCl (Tris: 0.05mol / L; NaCl: 2mol / L; pH7.5) buffer solution under ultrasonic conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com