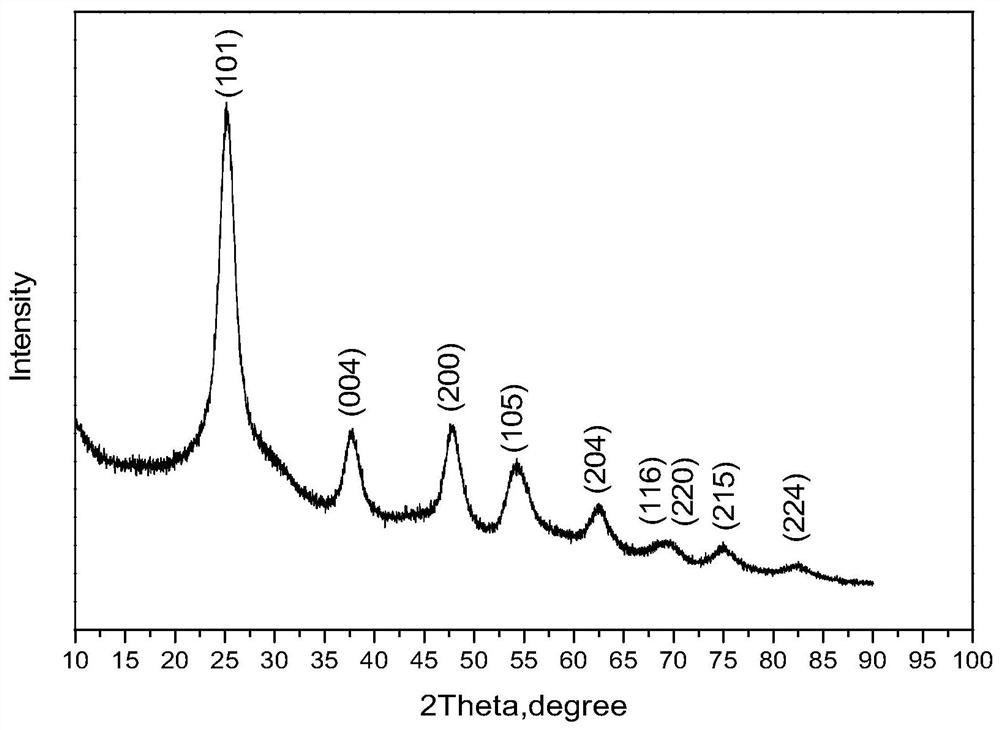

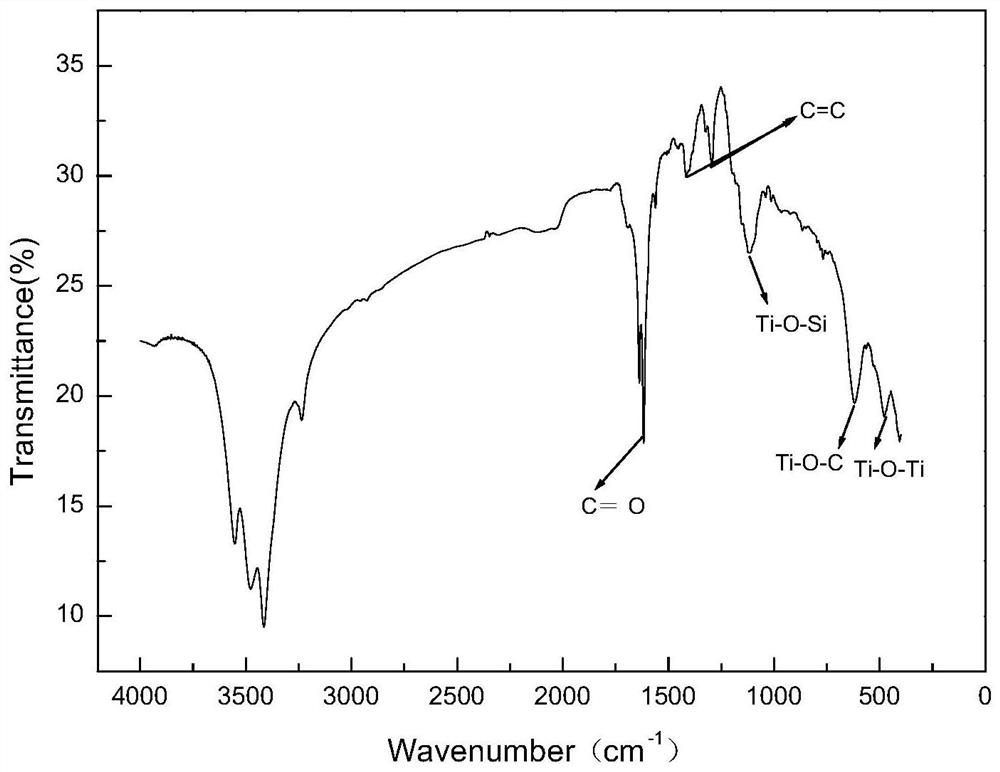

Graphene oxide-anatase type nanometer titanium dioxide composite modified sol and preparation thereof

A nano-titanium dioxide and anatase-type technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of inability to achieve titanium dioxide preparation, too fast reaction, etc. problems, to achieve superior mechanical, thermal and electrical performance, excellent proportioning effect, and increase the effect of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Pour a certain amount of absolute ethanol into a three-necked flask, weigh 8.5 g of tetrabutyl titanate, add it to absolute ethanol, and ultrasonically disperse for 0.5 h to obtain solution A.

[0033] (2) Pour a certain amount of absolute ethanol into the beaker, add 5 mg of graphene oxide into the beaker, and ultrasonically disperse for 0.5 h to obtain graphene oxide ethanol suspension B.

[0034] (3) Add a certain amount of ethanol into the beaker, add 1.35ml of deionized water, add 1.5ml of 36-38% hydrochloric acid, stir evenly, and obtain solution C.

[0035] (4) Pour the suspension B into the three-necked flask in the step (1), and then slowly titrate the solution C into the AB mixed liquid after magnetic stirring for 0.5h. 0.5h after the end of the magnetic stirring reaction to obtain the precursor.

[0036] (5) Add 0.575ml of KH-570 dropwise to the three-necked flask obtained from the precursor for modification, control the temperature of the water bath at ...

Embodiment 2

[0040] (1) Pour a certain amount of absolute ethanol into a three-necked flask, weigh 8.5 g of tetrabutyl titanate, add it to absolute ethanol, and ultrasonically disperse for 0.5 h to obtain solution A.

[0041] (2) Pour a certain amount of absolute ethanol into the beaker, add 5 mg of graphene oxide into the beaker, and ultrasonically disperse for 0.5 h to obtain graphene oxide ethanol suspension B.

[0042] (3) Add a certain amount of ethanol into the beaker, add 1.80ml of deionized water, add 1.5ml of 36-38% hydrochloric acid, stir evenly, and obtain solution C.

[0043] (4) Pour the suspension B into the three-necked flask in the step (1), and then slowly titrate the solution C into the AB mixed liquid after magnetic stirring for 0.5h. 0.5h after the end of the magnetic stirring reaction to obtain the precursor.

[0044] (5) Add 0.575ml of KH-570 dropwise to the three-necked flask obtained from the precursor for modification, control the temperature of the water bath at ...

Embodiment 3

[0048] (1) Pour a certain amount of absolute ethanol into a three-necked flask, weigh 8.5 g of tetrabutyl titanate, add it to absolute ethanol, and ultrasonically disperse for 0.5 h to obtain solution A.

[0049] (2) Pour a certain amount of absolute ethanol into the beaker, add 5 mg of graphene oxide into the beaker, and ultrasonically disperse for 0.5 h to obtain graphene oxide ethanol suspension B.

[0050] (3) Add a certain amount of ethanol into the beaker, add 2.25ml of deionized water, add 1.5ml of 36-38% hydrochloric acid, stir evenly, and obtain solution C.

[0051] (4) Pour the suspension B into the three-necked flask in the step (1), and then slowly titrate the solution C into the AB mixed liquid after magnetic stirring for 0.5h. 0.5h after the end of the magnetic stirring reaction to obtain the precursor.

[0052] (5) Add 0.575ml of KH-570 dropwise to the three-necked flask obtained from the precursor for modification, control the temperature of the water bath at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com