A kind of laser nano material processing method and processing system

A technology of nanomaterials and processing systems, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as poor stability, no monitoring device, complicated device, etc., and achieve good controllability, good accuracy, and monitoring low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

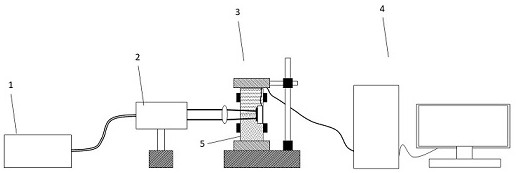

[0036] Such as figure 1 As shown, a laser nanomaterial processing system includes a laser 1 , a beam shaping module 2 , a target module 3 , and a monitoring module 4 .

[0037] Laser 1 is a visible light laser. After the laser output from laser 1 enters the beam shaping module 2, the laser spot is adjusted to an "8"-shaped spot; the "8"-shaped spot means that the shape of the laser spot is "8", and the light intensity has two equal maxima in the vertical direction;

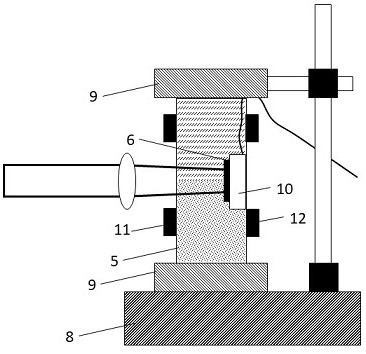

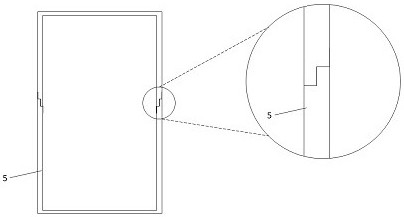

[0038] Such as figure 2 As shown, the target module 3 has a liquid pool 5 and a target seat 6 filled with liquid, and the liquid pool 5 has water and another organic solvent that does not dissolve with water; two target plates with different components are installed on the target seat 6. One target material 7 is set vertically on the upper side of the interface between water and organic solvent, and the other target material 7 is set on the lower side of the interface between water and organic solvent; On , th...

Embodiment 2

[0049] A kind of method utilizing described laser nano material processing system to carry out the method for preparing nano monolayer film, comprises the steps:

[0050] Step 1. Install the selected two targets 7 on the two target mounting positions of the target base 6 respectively and fix them; then install the target base 6 on the target rotating base 10; then use photosensitive paper to detect the light beam The position of the laser spot output by the shaping module 2, and then use a computer to adjust the position of the target 7 to match the spot;

[0051] Step 2: Inject water and an organic solvent into the liquid pool 5, and the interface between the organic solvent and water is located at the center of the target seat 6, so that one target is vertically arranged on the upper side of the interface between the water and the organic solvent, and the other target The material is arranged on the lower side of the interface between water and the organic solvent; the liqui...

Embodiment 3

[0057] This embodiment can prepare the structure of more than three components;

[0058] Step 1. Install the selected three target materials 7 on the two target material installation positions of the target base 6 respectively, and fix them. There are multiple installation positions around the center of the target base on the target base. There are four targets in total for the three types of targets. There are two pieces of Au, one piece of ZnO, and one piece of PbS; ZnO and PbS are arranged adjacently, and two pieces of Au targets are set on their opposite sides; after that, the target base 6 is installed on the target rotating base 10; The position of the laser spot output by the beam shaping module 2, and then use a computer to adjust the position of the target 7 to match the spot;

[0059] Step 2: Inject water and an organic solvent into the liquid pool 5, and the interface between the organic solvent and water is located at the center of the target seat 6, so that one Zn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com