A kind of phosphorylcholine polyethylene glycol modified chitosan and preparation method thereof

A polyethylene glycol modification and phosphorylcholine technology, which is applied in the field of biomaterials and biomedical polymer materials, can solve the problems of poor hydrophilicity of nanospheres, achieve non-toxicity, simple method, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

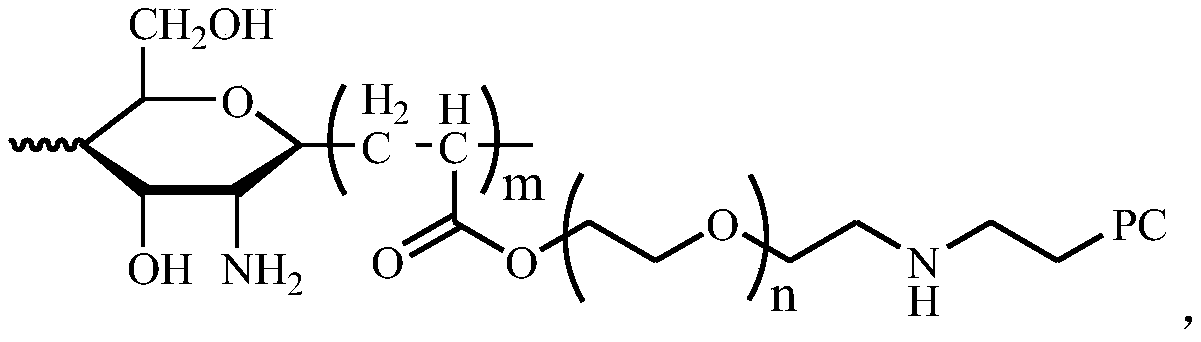

[0052] 1. Preparation of phosphorylcholine-based polyethylene glycol

[0053] Dissolve 0.1 mol of monoamino-terminated polyethylene glycol (n=10) in N,N-dimethylformamide, add 0.12 mol of hexanaldophosphorylcholine compound, react at 50°C for 12 hours, and cool After cooling down to 8°C, add NaBH with a concentration of 0.02g / mL 4 Methanol solution (wherein NaBH 4 The amount of the substance is 0.24 mol), the temperature was raised to 20°C, the reaction was carried out for 12 hours, 6 times the volume of glacial ether was settled, suction filtered, washed with glacial ether, and dried under vacuum at room temperature to obtain polyethylene glycol with a phosphorylcholine group at the end.

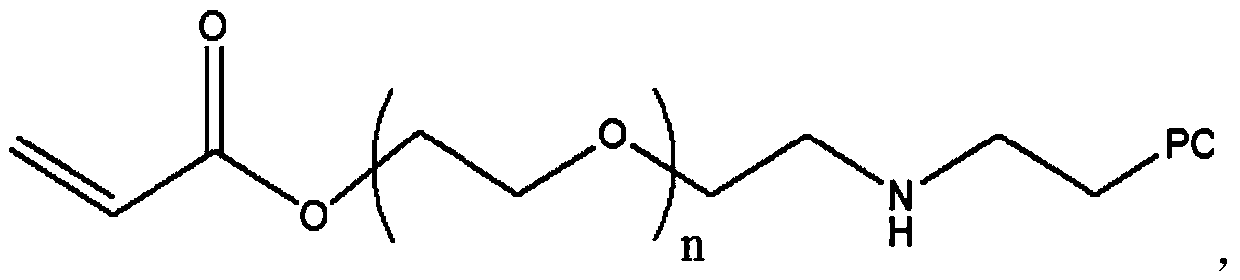

[0054] 2. Preparation of acrylate-capped phosphorylcholine-based polyethylene glycol

[0055] Dissolve 0.01mol of phosphorylcholine-based polyethylene glycol (n=10) and 0.012mol of triethylamine in anhydrous dichloromethane, cool down to -5°C to 3°C, slowly add 0.012mol of acryloyl chlori...

Embodiment 1

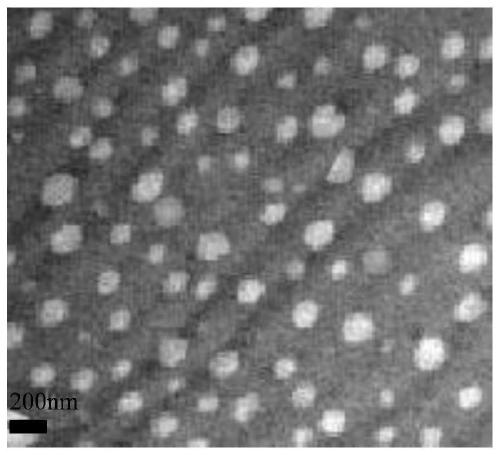

[0066] Dissolve 1g of chitosan (95% degree of deacetylation, molecular weight: 200,000) in 10mL of 0.1mol / L acetic acid aqueous solution, deoxygenate with nitrogen, add 0.027g of potassium persulfate (0.01mol / L), react at 60°C for 30min, Cool down to 50°C, add 0.2g of acrylate-capped phosphorylcholine-based polyethylene glycol, react for 6h under nitrogen, adjust pH to 8-9 with 5% sodium hydroxide solution, filter, and filter the cake with 80% Wash with ethanol and acetone, and vacuum-dry at 35°C to constant weight to obtain phosphorylcholine-based polyethylene glycol-modified chitosan (number-average molecular weight: 132,000). Depend on figure 1 It can be seen that the phosphorylcholine-based polyethylene glycol-modified chitosan nanoparticles prepared in this example have regular shapes, no agglomeration, and smooth surfaces.

[0067] Weigh 0.1g, 0.25g, 0.4g, 0.6g of phosphorylcholine-based polyethylene glycol-modified chitosan and slowly add them to 5mL deionized water un...

Embodiment 2

[0069] Dissolve 1g of chitosan (90% degree of deacetylation, molecular weight: 250,000) in 10mL of 0.1mol / L acetic acid aqueous solution, deoxygenate with nitrogen, add 0.027g of ammonium persulfate (0.01mol / L), react at 60°C for 30min, Cool down to 50°C, add 0.4g of acrylate-capped phosphorylcholine-based polyethylene glycol, react for 6h under nitrogen, adjust pH to 8-9 with 5% sodium hydroxide solution, filter, and use 80% ethanol, Washed with acetone, dried in vacuum at 35°C to constant weight to obtain phosphorylcholine-based polyethylene glycol-modified chitosan (number-average molecular weight: 176,000).

[0070] Weigh 0.25g of phosphorylcholine-based polyethylene glycol-modified chitosan and slowly add it to 5mL deionized water under magnetic stirring to obtain phosphorylcholine-based polyethylene glycol-modified chitosan nanoparticles, denoted as C2, the concentration is 5g / dL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com