Combined assembly type tunnel wastewater treatment device and wastewater treatment system

A wastewater treatment and combined assembly technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of long construction period, scattered process, not compact, etc., and achieve reuse High efficiency, cost reduction, and strong shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

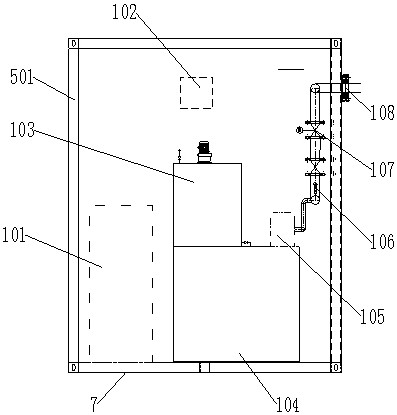

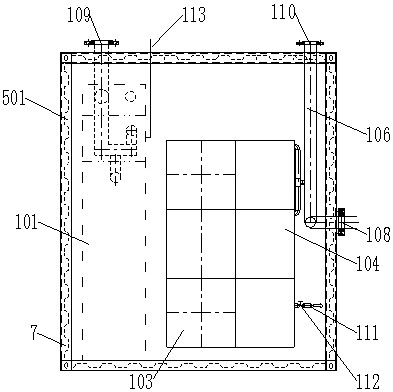

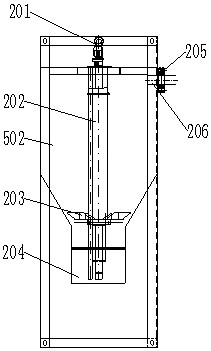

[0133] Embodiment 2, as shown in Figure 1-2:

[0134] A combined assembled tunnel wastewater treatment system installed with the combined assembled tunnel wastewater treatment device described in Embodiment 1, comprising a main box 7, a first sub-box module 501, a second sub-box module 501, and a second sub-box are arranged in the main box 7 Module 502, the third binning module 503, and the fourth binning module 504, wherein:

[0135] The first sub-box module 501 is provided with a dehydration dosing and sub-box assembly;

[0136] The second sub-box module 502 is provided with a swirling sand settling sub-box assembly;

[0137] The third sub-box module 503 is provided with a coagulation and mud discharge sub-box assembly;

[0138] The fourth binning module 504 is provided with a high-efficiency sedimentation binning assembly;

[0139] The first sub-box module 501 integrated with the dehydration and dosing sub-box assembly, the second sub-box module 502 integrated with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com