High-fluidity and high-wear-resistance thermoplastic polyurethane and preparation method thereof

A thermoplastic polyurethane, high wear resistance technology, used in the field of polyurethane materials, can solve the problems of imperfect appearance, insufficient gloss, poor wear resistance, etc., and achieve the effects of high elongation at break, high hardness and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

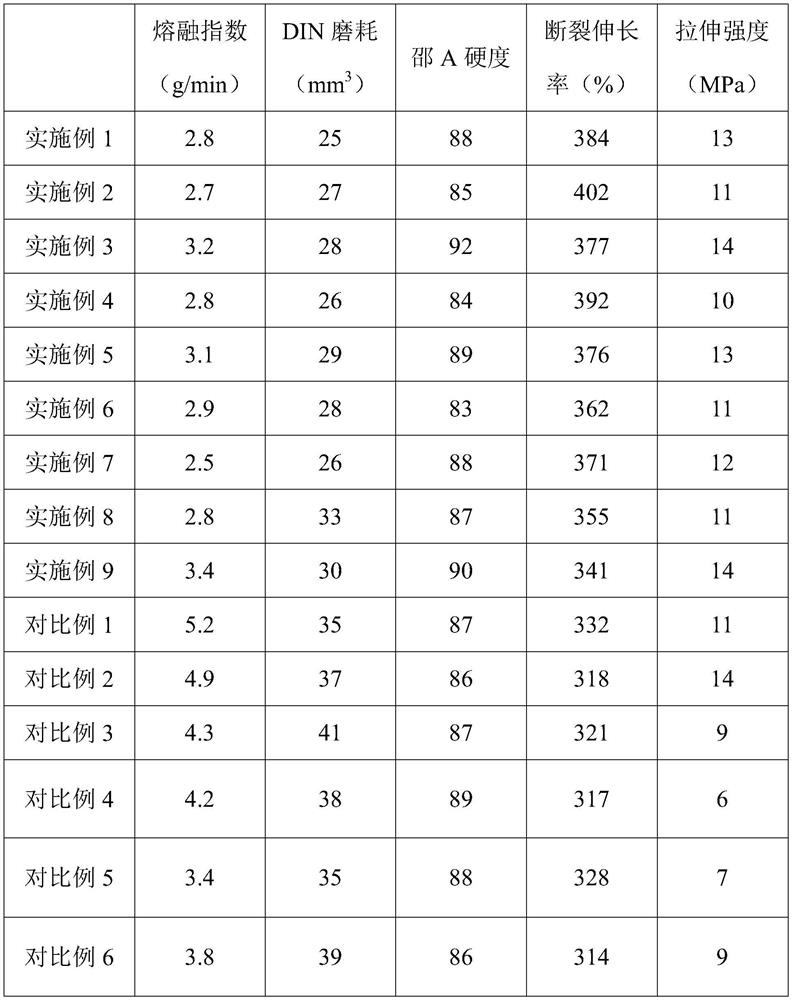

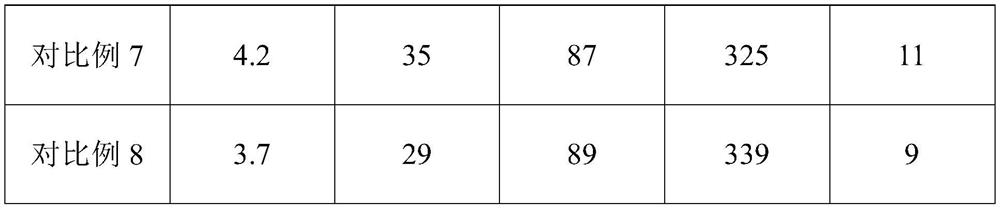

Examples

Embodiment 1

[0053] This embodiment provides a thermoplastic polyurethane with high fluidity and high wear resistance, and the thermoplastic polyurethane includes component A and component B;

[0054] The raw materials for the preparation of the component A include the following components in parts by weight: 30 parts of diisocyanate (toluene diisocyanate), 55 parts of polycaprolactone polyol (purchased from Hunan Juren Chemical New Material Co., Ltd., weight average molecular weight 530g / mol, brand name is 2055), 12 parts of hydroxyl-terminated polybutadiene acrylonitrile (purchased from Zibo Qilong Chemical Co., Ltd.), 7 parts of amine chain extender (3,5-diamine-4-chlorobenzene isobutyl formate) and 0.03 part of catalyst (dibutyltin dilaurate);

[0055] The raw materials for the preparation of component B include the following components in parts by weight: 4 parts of nano silicon dioxide, 6 parts of carboxymethyl cellulose (purchased from Weiyi Chemical (Suzhou) Co., Ltd., the brand is...

Embodiment 2

[0061] This embodiment provides a thermoplastic polyurethane with high fluidity and high wear resistance, and the thermoplastic polyurethane includes component A and component B;

[0062] The raw materials for the preparation of component A include the following components in parts by weight: 20 parts of diisocyanate (toluene diisocyanate), 50 parts of polycaprolactone polyol (purchased from Hunan Juren Chemical New Material Co., Ltd., weight average molecular weight 400g / mol, the grade is 2044), 15 parts of hydroxyl-terminated polybutadiene acrylonitrile (purchased from Zibo Qilong Chemical Co., Ltd.), 5 parts of amine chain extender (ethylenediamine) and 0.01 part of catalyst (dilaurel dibutyltin acid);

[0063] The raw materials for the preparation of component B include the following components in parts by weight: 3 parts of nano silicon dioxide, 4 parts of carboxymethyl cellulose (purchased from Weiyi Chemical (Suzhou) Co., Ltd., the brand is BH2000, and the viscosity is ...

Embodiment 3

[0069] This embodiment provides a thermoplastic polyurethane with high fluidity and high wear resistance, and the thermoplastic polyurethane includes component A and component B;

[0070] The raw materials for the preparation of the component A include the following components in parts by weight: 40 parts of diisocyanate (toluene diisocyanate), 60 parts of polycaprolactone polyol (purchased from Hunan Juren Chemical New Material Co., Ltd., weight average molecular weight 1000g / mol, the grade is 2102), 10 parts of hydroxyl-terminated polybutadiene acrylonitrile (purchased from Zibo Qilong Chemical Co., Ltd.), 10 parts of amine chain extender (ethylenediamine) and 0.05 part of catalyst (dilaurel dibutyltin acid);

[0071] The raw materials for the preparation of component B include the following components in parts by weight: 5 parts of nano silicon dioxide, 8 parts of carboxymethyl cellulose (purchased from Weiyi Chemical (Suzhou) Co., Ltd., the brand is BH2000, and the viscosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com