Plasticizer, and preparation method and application thereof

A plasticizer and reaction technology, applied in the field of plasticizer and its preparation, to achieve the effects of simple synthesis, low biological toxicity, and renewable raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

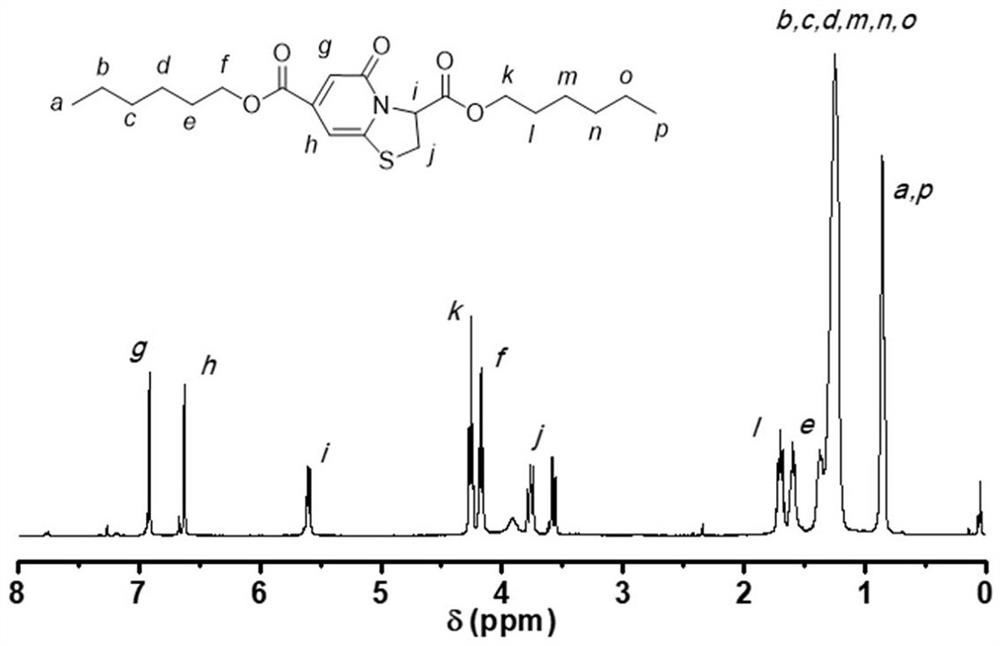

[0038] Mix 10 millimoles of pyridone diacid and 30 millimoles of n-hexanol, add 25 millimoles of thionyl chloride dropwise at 0°C, after the addition is complete, react at room temperature (25°C) for 24 hours, then spin Steam to remove unreacted thionyl chloride, rectify to obtain dihexyl pyridone diacid, dihexyl pyridone diacid 1 H NMR spectrum see figure 1 .

Embodiment 2

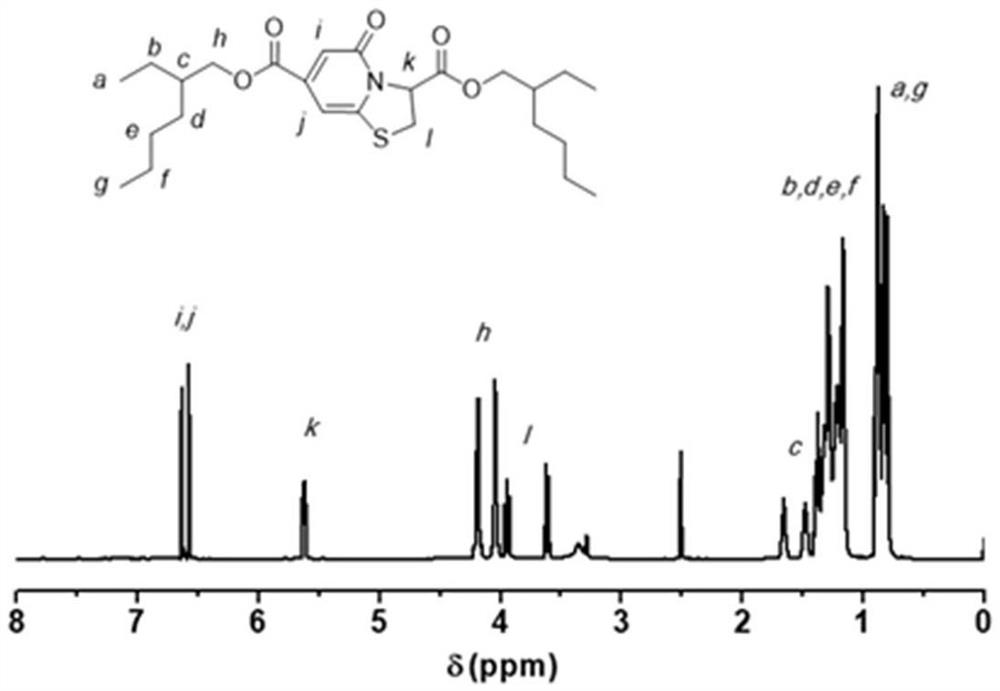

[0040] Mix 20 mmoles of pyridone diacid, 50 mmoles of isooctyl alcohol, 20 micromoles of p-toluenesulfonic acid and 150 ml of toluene in a round bottom flask, connect to a toluene azeotrope device, and heat at 130°C After reacting for 24 hours, the toluene was removed by rotary evaporation and rectification to obtain diisooctyl pyridonedioate. di-isooctyl pyridone dioate 1 H NMR spectrum see figure 2 .

Embodiment 3

[0042] Mix 20 mmoles of dimethyl pyridone diacid, 50 mmoles of isooctyl alcohol, 20 micromoles of tetrabutyl titanate and 150 ml of toluene in a round bottom flask, connect to a toluene azeotrope device, and Heating and reacting at 130°C for 24 hours, then rotary evaporation to remove toluene and rectification to obtain di-isooctyl pyridone dioate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com