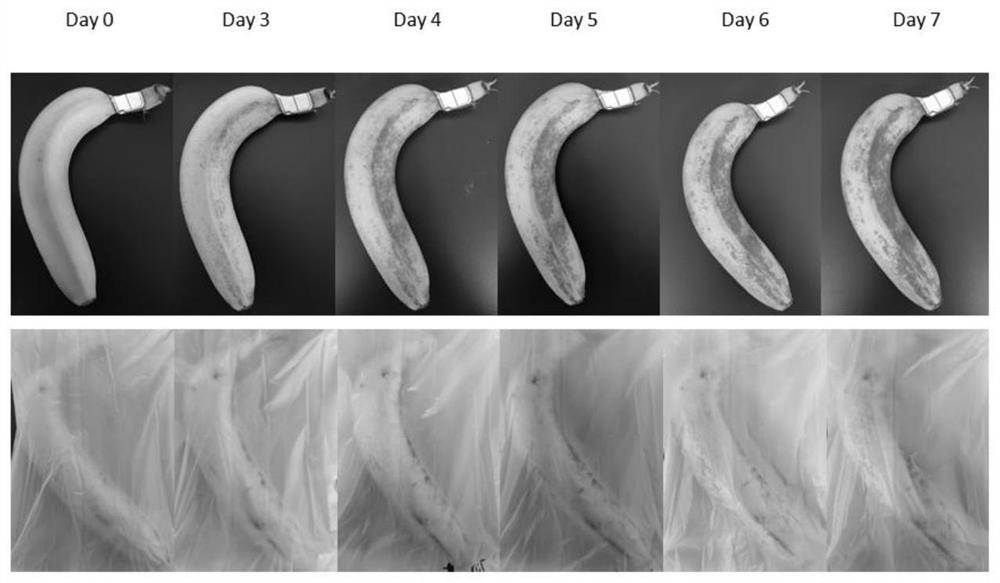

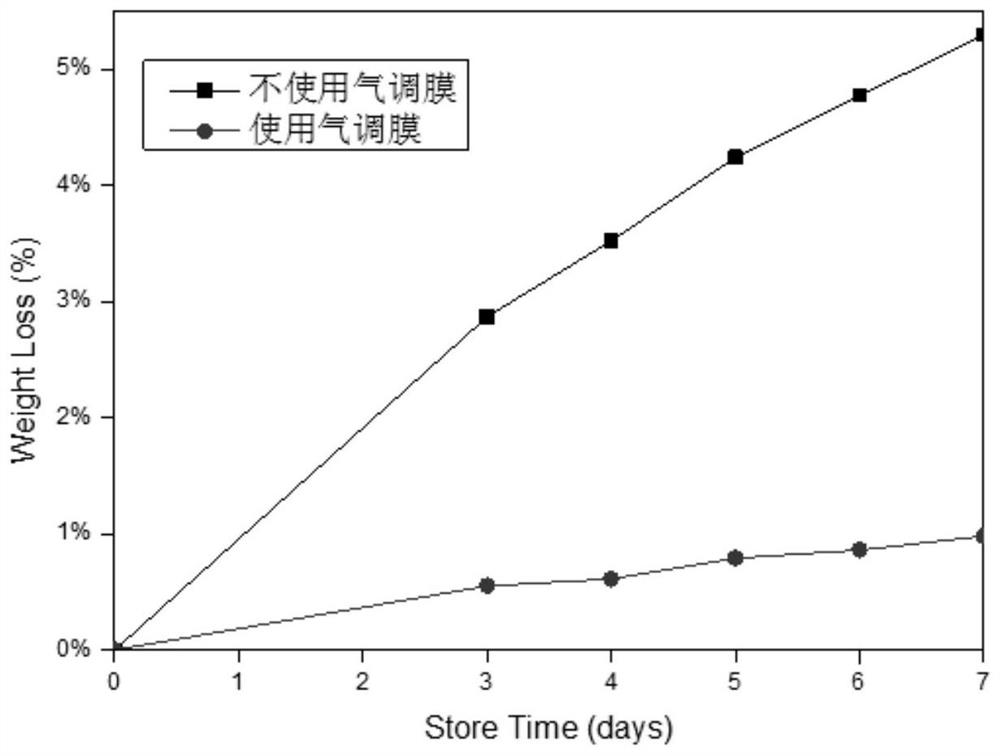

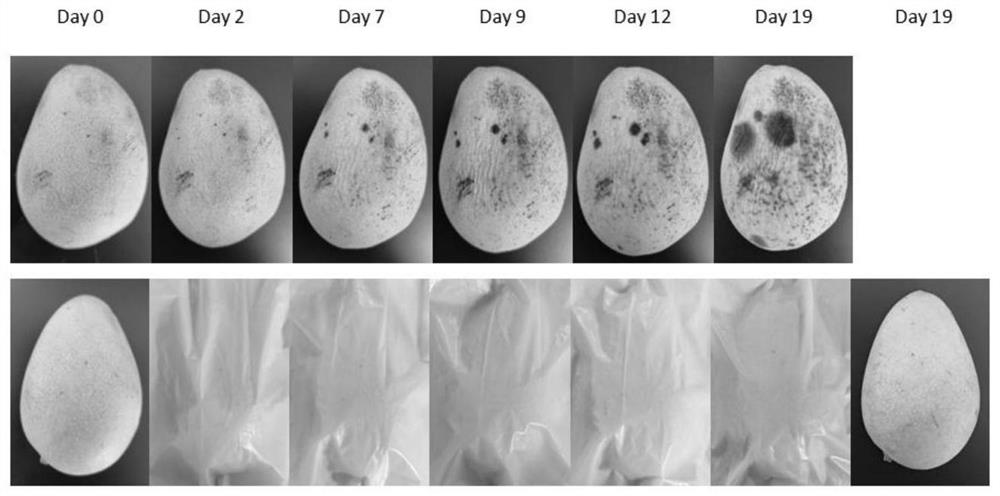

Biodegradable controlled atmosphere film capable of prolonging shelf life of fruits and preparation method thereof

A technology of biodegradation and biodegradation of polyester, which is applied in the field of biodegradable modified atmosphere membrane and its preparation, can solve the problems of poor material safety, white pollution, and too good gas barrier performance, so as to increase production, promote separation, reduce The effect of the number of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A biodegradable atmosphere-modified film for prolonging the shelf life of high-breathing-intensity fruits is made of the following components by weight: by weight, 60 parts of PBAT, 33.49 parts of PLA, 1 part of nano-titanium dioxide, three Composed of 0.01 parts of ferric chloride, 5 parts of maleic anhydride grafted PBAT and 0.5 parts of diatomaceous earth, then dry the above components at 60°C overnight, mix them evenly, and feed them into the twin-screw extruder through the feeding port. The product is pelletized after water cooling. Then, it is blown into a film by a film blowing machine, cooled and wound up to obtain the modified atmosphere film. Among them, the feed inlet temperature of the twin-screw extruder is 100°C, the temperature of the second zone to the fifth zone is 160°C; the feed inlet temperature of the film blowing machine is 145°C, and the rest section temperature is 155°C.

Embodiment 2

[0036] A biodegradable atmosphere-modified film for extending the shelf life of high-breathing-intensity fruits is made from components comprising the following parts by weight: in parts by weight, 80 parts of PBAT, 12.69 parts of polypropylene carbonate, nano-titanium dioxide 4 parts, 0.01 parts of graphene oxide, 3 parts of acrylic grafted polypropylene carbonate and 0.3 parts of silicon dioxide, then dry the above components at 60°C overnight, mix them evenly, and feed them into the twin-screw from the feeding port In the extruder, the product is water-cooled and pelletized. Then, it is blown into a film by a film blowing machine, cooled and wound up to obtain the modified atmosphere film. Among them, the feed inlet temperature of the twin-screw extruder is 90°C, the temperature of the second zone to the fifth zone is 150°C; the feed inlet temperature of the film blowing machine is 140°C, and the temperature of the rest section is 150°C.

Embodiment 3

[0038] A biodegradable atmosphere-modified film for extending the shelf life of high-breathing-intensity fruits is made from components comprising the following parts by weight: in parts by weight, 85 parts of PBAT, polysuccinic acid-adipate-butylene 5.90 parts of glycol ester, 8 parts of nano-zinc oxide, 0.001 part of nano-gold ion and nano-silver ion, 1 part of oxazoline grafted PBAT and 0.1 part of silicon dioxide, and then bake the above components overnight at 60 ° C Dry, mix evenly, put into the twin-screw extruder from the feeding port, and the product will be pelletized after water cooling. Then, it is blown into a film by a film blowing machine, cooled and wound up to obtain the modified atmosphere film. Among them, the feed inlet temperature of the twin-screw extruder is 95°C, the temperature of the second zone to the fifth zone is 155°C; the feed inlet temperature of the film blowing machine is 143°C, and the rest section temperature is 152°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com