Desulfurization and denitrification system

A desulfurization and denitrification, H2O2 technology, applied in the field of desulfurization and denitrification systems, can solve the problems of high investment and operation costs, large floor area, pressure fluctuations, etc., and achieve the goals of improving catalytic oxidation efficiency, saving floor space, and high gas hourly space velocity ratio Effect

Pending Publication Date: 2021-08-17

HUAZHONG UNIV OF SCI & TECH

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The simple series arrangement of the existing selective catalytic reduction method and wet desulfurization system (SCR-WFGD) in thermal power plants has the disadvantages of large footprint, complex system and high investment and operation costs.

[0003] Chinese patent CN105032142A provides an inverted U-shaped pre-oxidizer. The flue gas is accelerated in the venturi tube of the inverted U-shaped pre-oxidizer. Carrying a gas-phase composite oxidant into the main part of the oxidizer, a porous baffle is arranged at the outlet of the Venturi tube to enhance the turbulent effect of the flue gas. In this device, the flue gas needs to pass through the Venturi tube and the porous baffle, and the pressure fluctuation and pressure drop Large, not conducive to the treatment of large flue gas conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0060]

Embodiment 2

[0062]

Embodiment 3

[0064]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

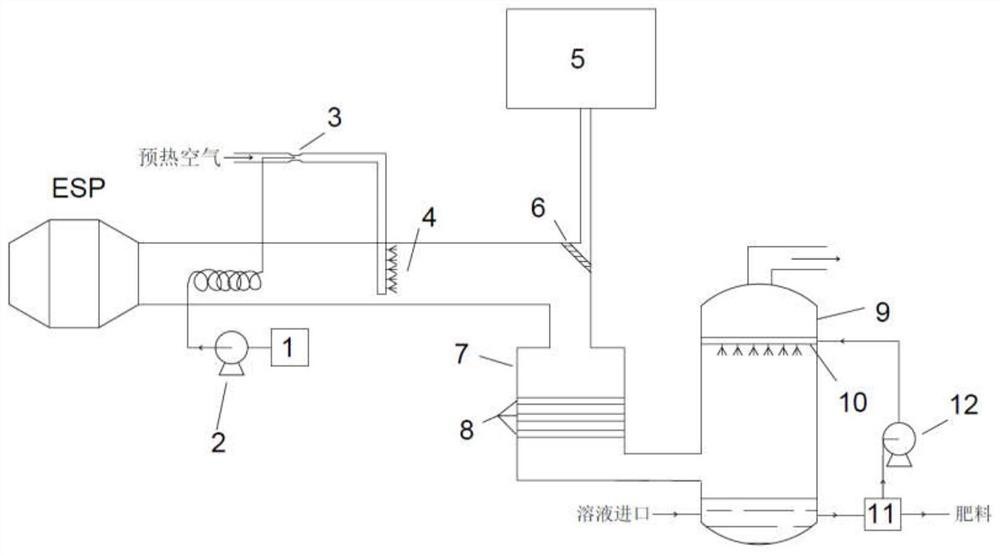

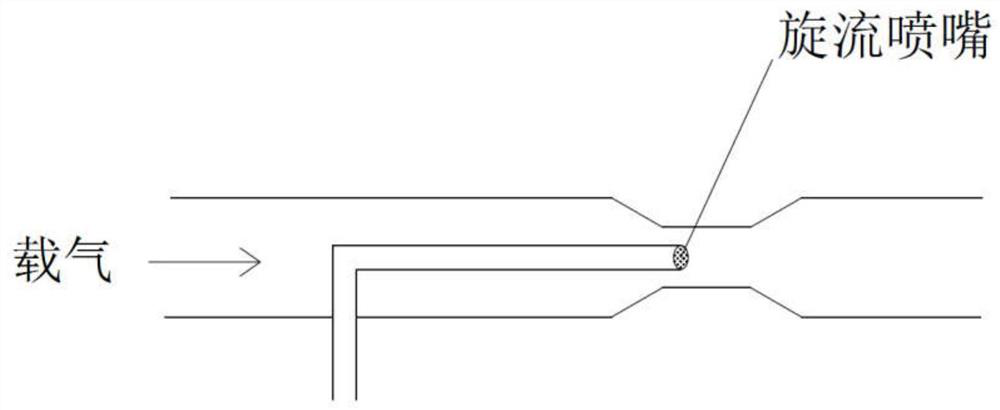

The invention belongs to the related technical field of flue gas purification, and discloses a desulfurization and denitrification system which comprises an H2O2 supply device, an H2O2 conveying pipeline, an H2O2 gasification mixing device, a microwave generation device and a catalytic oxidation device, the H2O2 conveying pipeline is located in a flue gas pipeline, one end of the H2O2 conveying pipeline is connected with the H2O2 supply device, and the other end of the H2O2 conveying pipeline is connected with the H2O2 gasification mixing device; a spraying grid is arranged at the outlet end of the H2O2 gasification mixing device, the spraying grid is located in the flue gas pipeline, and mixed gas of carrier gas and H2O2 is atomized through the spraying grid and then mixed with flue gas; the microwave generation device and the catalytic oxidation device are connected with the flue gas pipeline, are positioned at the downstream of the spraying grid, and are used for catalytically oxidizing atomized H2O2 into OH free radicals. Through combination of heating atomization and microwave catalysis, H2O2 rapidly excites a large number of OH free radicals to meet the requirements of flue gas desulfurization and denitrification, the efficiency is high, and the size is small.

Description

Technical field [0001] The present invention belongs to the field of flue gas purification, and more particularly to a desulfurization denitration system. Background technique [0002] At present, coal consumption in my country's energy consumption is still dominated. A large amount of pollutants such as sulfur dioxide and nitrogen oxides during the coal-fired power generation process will result in serious problems such as smog, raining, photochemical pollution, and is very bad about the environment. NOx emission standards have become more stringent with the continuous improvement of NOx governance technology and environmental protection, and the current standard specifies that the emission concentration of nitrogen oxides shall not exceed 50 mg / m3, respectively. The simple series cloth of the existing selective catalytic reduction method and wet desulfurization system (SCR-WFGD) in the thermal power plant has a large coverage area, the system is complex and the cost of invest...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/60B01D53/86B01D53/78B01D53/88B01D53/00

CPCB01D53/60B01D53/8637B01D53/78B01D53/88B01D53/007B01D2258/0283B01D2251/106B01D2259/806

Inventor 王贲孙路石刘丰

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com