Processing method for high-barrier online coated polyester film

A technology of polyester film and processing method, used in coatings, other household appliances, flat products, etc., can solve the problem that polyester film cannot meet high barrier properties, safety and functionality, affects the barrier properties of aluminum foil, and is easy to produce aluminum foil. Cracks and other problems, to achieve the effect of excellent rollability, enhanced adhesion, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below.

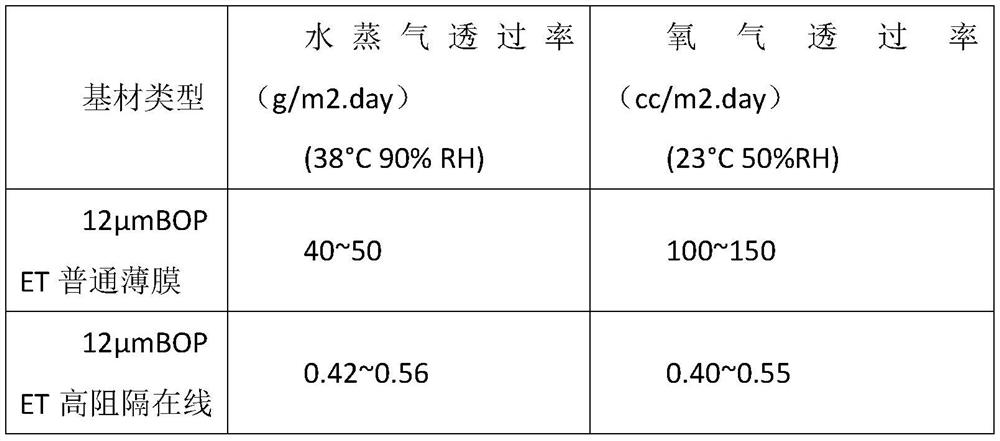

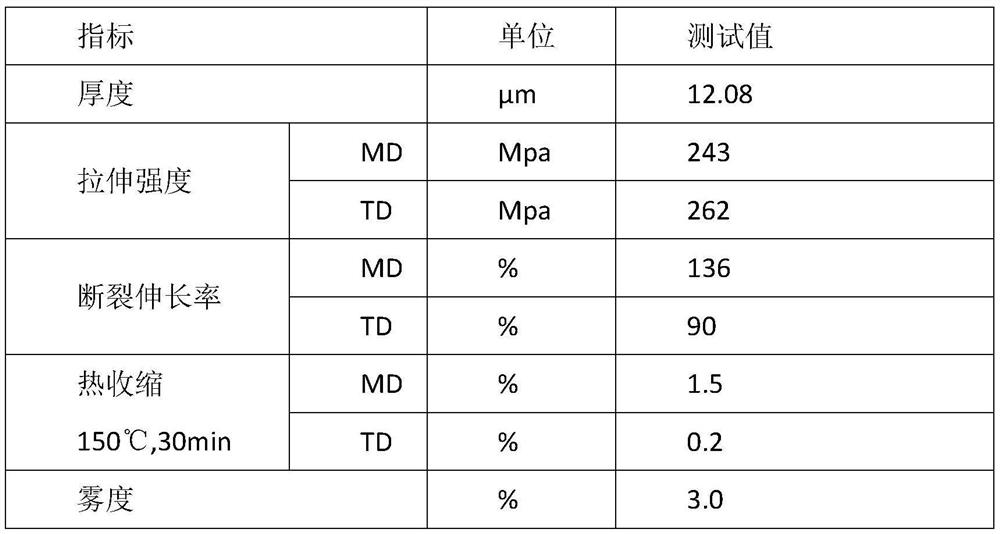

[0034] In order to solve the application that needs to be aluminum-plated on the surface of the polyester film to block water and oxygen, by using the self-designed online surface treatment equipment, the online surface treatment is carried out on the surface of the film, while maintaining the excellent physical properties of the polyester film. , improve the barrier properties to oxygen, water vapor or carbon dioxide gas, the invention provides a processing method for high-barrier online coated polyester film, characterized in that: in the production process of conventional biaxially stretched polyester film to increase the online surface treatment , that is, after longitudinal stretching, the film is surface-treated by self-designed online coating equipment, and the mixed solvent used in the surface treatment layer is a water-based coating; the line surface treatment processing method includes the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com