Hollow-core photonic crystal fiber resonant gyroscope based on free-form surface lens coupling

A technology of hollow-core photonic crystals and curved lenses, which is applied in the field of inertial sensing technology and integrated optics, can solve the problems of less lens reports, achieve reduced volume and installation difficulty, insensitivity to environmental changes, and simplify preparation and installation processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation process of the fiber resonator gyroscope of the present invention comprises the following steps:

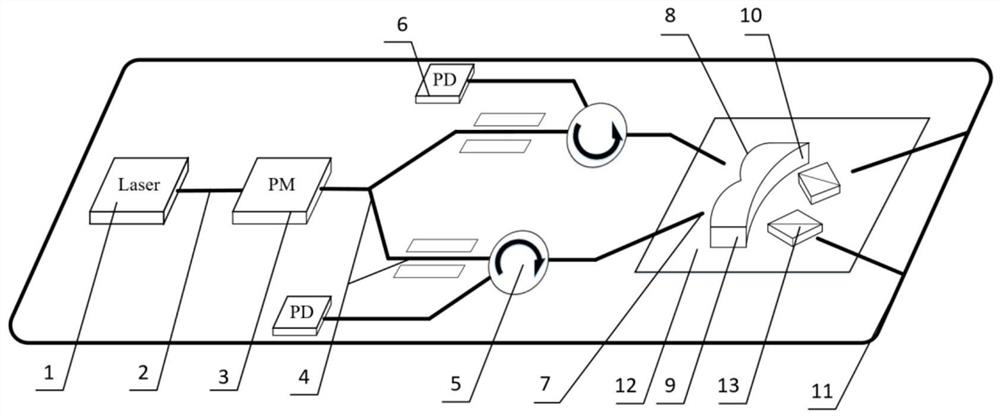

[0042] 1) Connect to an optical transmission system, including a narrow linewidth laser light source 1, a first polarization maintaining fiber 2, a phase modulator 3, a Y waveguide 4, a circulator 5, and a photodetector 6.

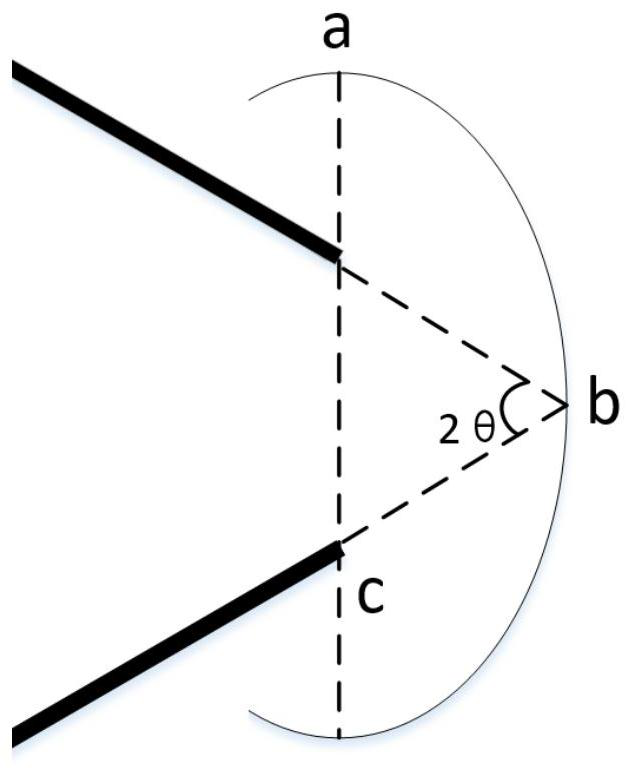

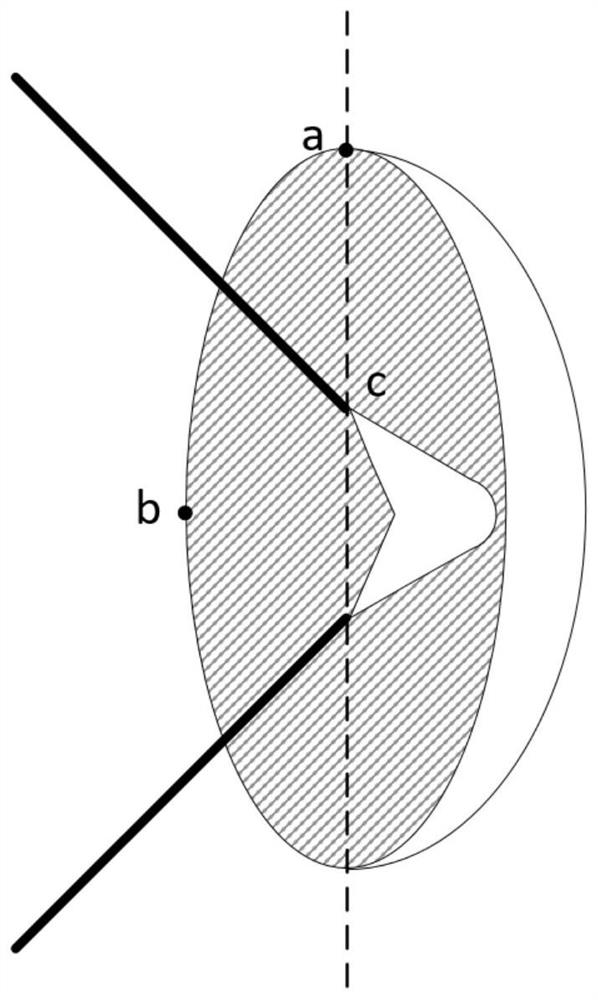

[0043] 2) Design the free-form surface lens coupler 9 . Wherein the second surface 10 is an ellipsoid, and the head and tail end surfaces of the hollow-core optical fiber ring 11 are on the two foci of the long axis of the ellipsoid, which can satisfy mutual coupling after being reflected by the ellipsoid. The intersection of the extension lines at both ends of the hollow-core optical fiber ring 11 coincides with the center of the ellipsoid.

[0044] 3) According to the designed second surface 10, the first surface 8 can be designed with a free-form surface, and the first surface 8 can be designed with a bicoinczernike surface, so that...

Embodiment

[0049] In this embodiment, the hollow-core photonic crystal fiber resonator gyro based on the free-form surface lens, the first polarization-maintaining fiber 2 is HC-1550-02 type, the center wavelength of the narrow-linewidth laser light source 1 is 1550nm, and the material of the free-form surface lens coupler 9 for BK7;

[0050] like figure 1 As shown, the light emitted by the narrow-linewidth laser source 1 enters the first polarization-maintaining optical fiber 2, and the phase modulator 3, Y waveguide 4, circulator 5, and photodetector 6 are arranged in sequence along the direction of the optical path. The free-form surface lens coupler 9, the polarization beam splitting prism 13, and the hollow fiber ring 11 form a resonant cavity. The head and tail end faces of the second polarization-maintaining fiber 7 , the free-form surface lens coupler 9 , the polarizing beam splitting prism 13 , and the hollow-core fiber ring 11 are mounted together on an etched silicon chip 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com