Ferroelectric film capacitor and preparation method thereof

A ferroelectric film and capacitor technology, applied in the field of microelectronics, can solve the problems of low saturation polarization of ferroelectric film capacitors, low energy storage density and high residual polarization of ferroelectric film capacitors, and achieve high dielectric strength and high Discharge energy density, energy storage efficiency, and the effect of fast discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

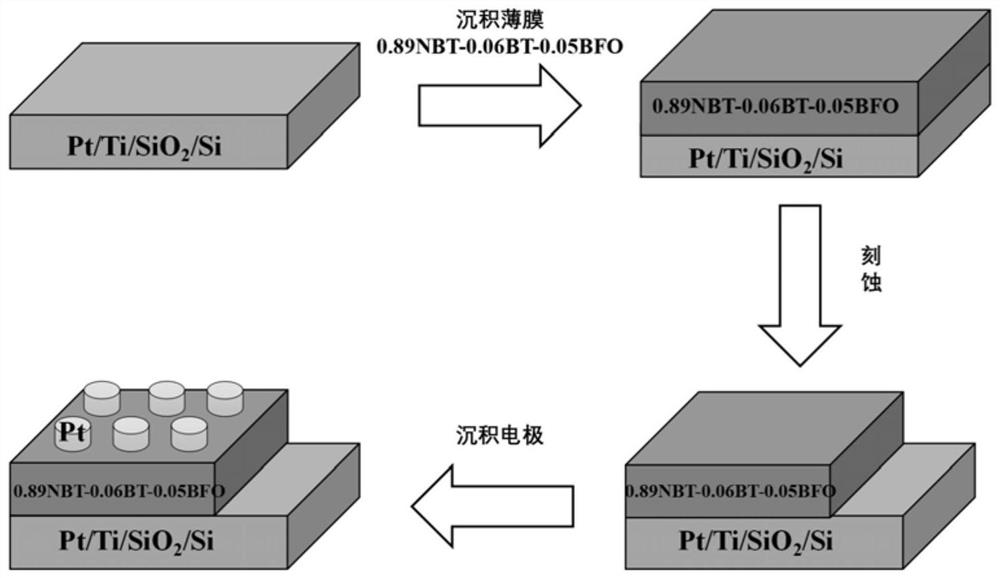

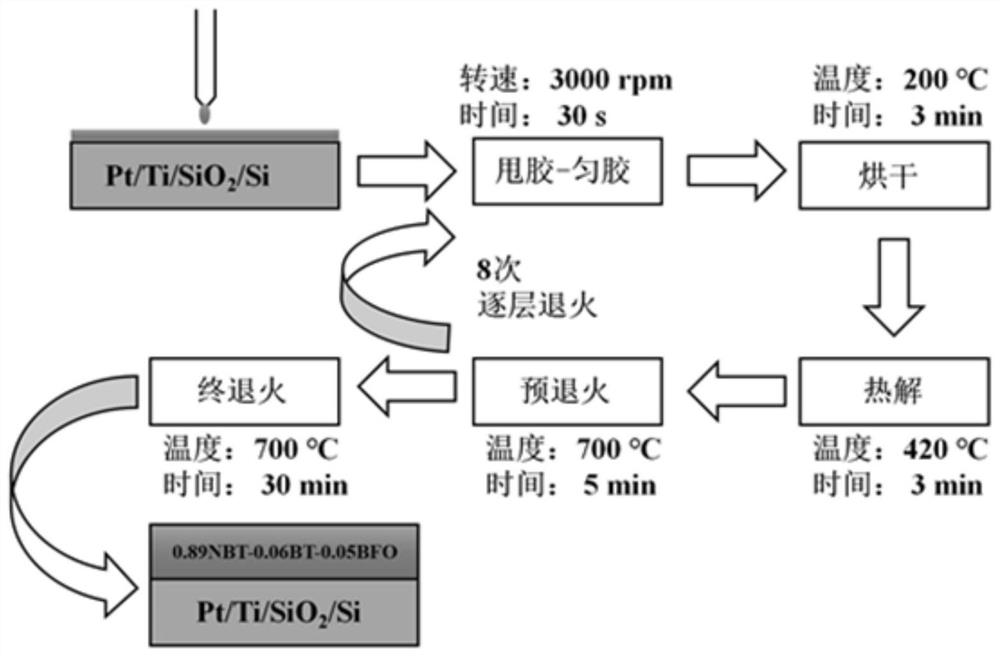

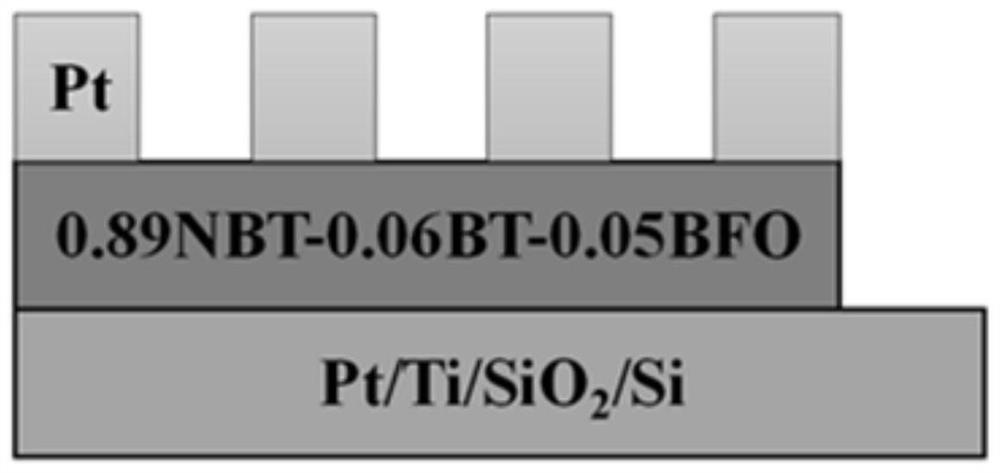

[0054]This embodiment is a BFO-doped NBT-BT lead-free ferroelectric film capacitor (Pt / 0.89NBT-0.06BT-0.05BFO / (Pt / Ti / SiO 2 / Si)) preparation (eg figure 1 shown), the specific preparation steps are as follows:

[0055] 1. Configuration of the precursor solution of bismuth sodium titanate-barium titanate (NBT-BT) doped with bismuth ferrite (BFO): Weigh 0.02356g barium acetate ((CH3COO) 2 Ba), 0.5282g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), 0.1211g sodium acetate (CH 3 COONa·3H 2 O), 0.0404g iron nitrate (Fe(NO 3 ) 3 9H 2 0) be dissolved in the co-solvent of 8.7ml 2-methoxyethanol and acetic acid (both ratio is about 1:1), and fully dissolve, mix homogeneously under the operation of magnetic stirrer;

[0056] 2. Use a graduated cylinder to measure 0.65ml of tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) into 0.65ml of acetylacetone stable solution, then add 8.7ml of 2-methoxyethanol and acetic acid (ratio of about 1:1) co-solvent, and stir in a magnetic stirrer (400-500r / s) f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com