Aqueous zinc ion battery and positive electrode material

A zinc-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor stability, slow diffusion, low cycle life, etc., achieve stable performance, increase electrical conductivity, and enhance electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

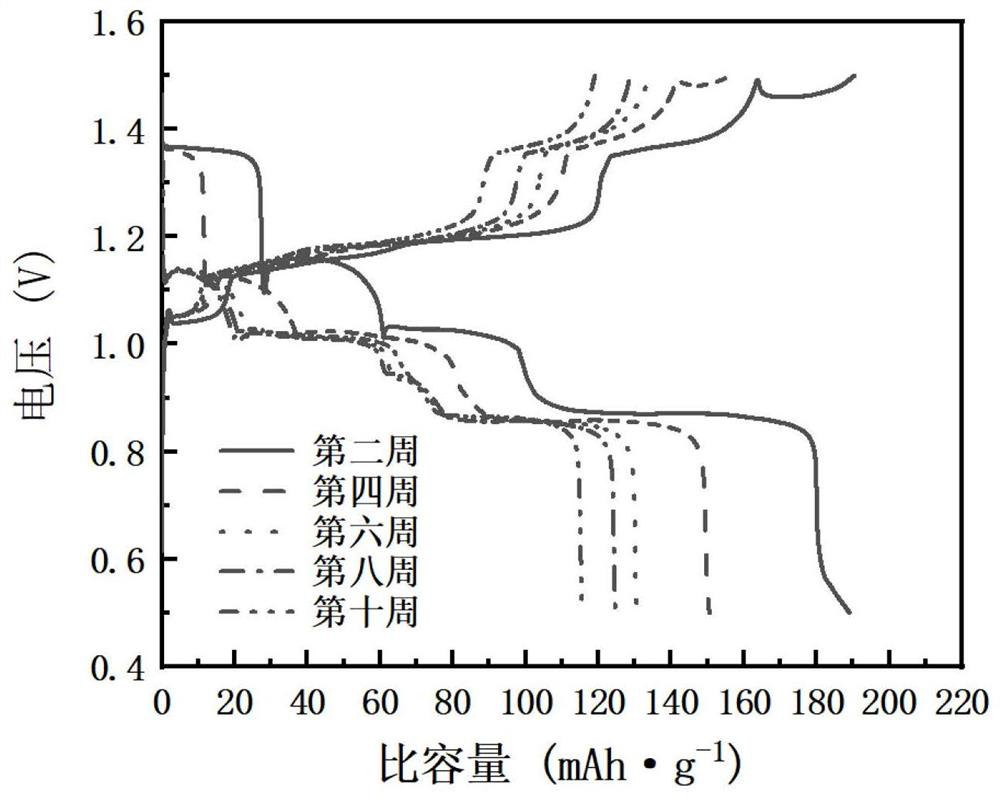

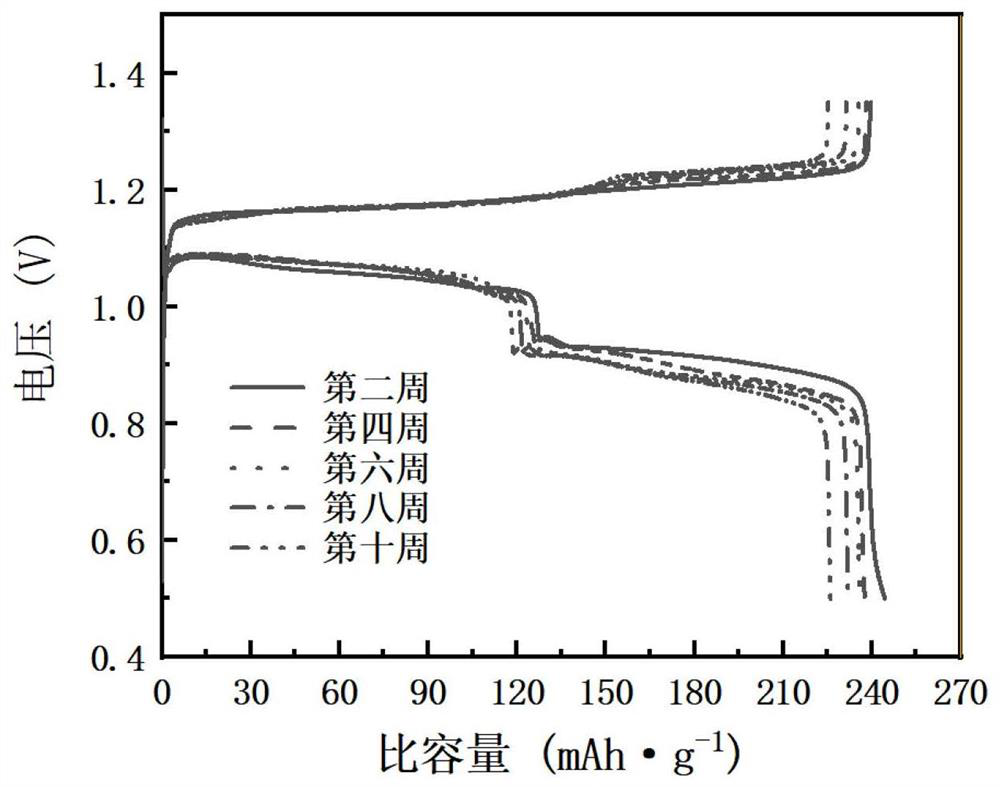

Embodiment 1

[0039] 1. Preparation of TTF-TCNQ complex:

[0040] Weigh TTF and TCNQ according to the mass ratio of 1:1; Pour the weighed TTF and TCNQ into different mortars respectively, dissolve them with appropriate amount of acetonitrile, and grind fully with the mortar at the same time, and grind the fully TTF and fully ground TCNQ are mixed together, and the two are fully ground again; vacuum filtration is performed with a vacuum filtration device, and after the suction filtration is completed, the material on the filter paper is put into a vacuum drying oven for drying, and the temperature is set at 60 ℃, the time is 720min.

[0041] 2. Preparation of positive electrode (TTF-TCNQ:SP:PTFE=6:3:1):

[0042] Weigh 30mg of TTF-TCNQ and pour it into a mortar; then weigh 15mg of SP (conductive carbon black) and pour it into a mortar, mix it with TTF-TCNQ with a pestle, grind it for about 20min, and use 10 Take about 8.33 mg of 60% PTFE with a microliter pipette gun and add it to the morta...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that TTF and TCNQ are weighed according to the mass ratio of 5:1.

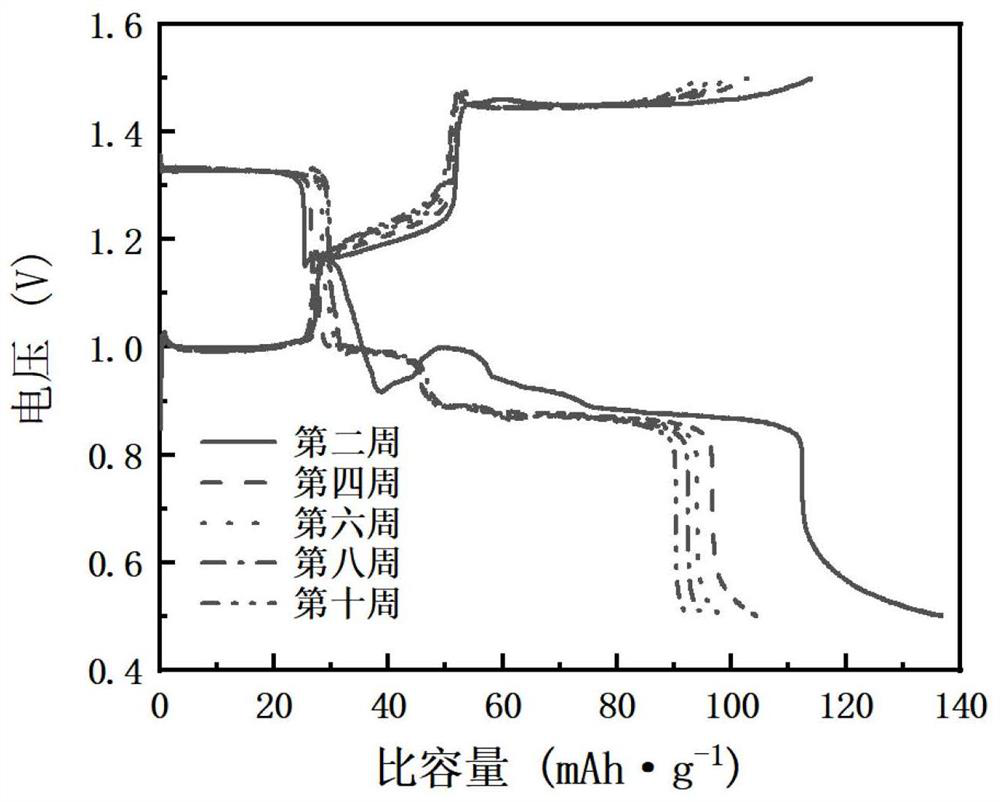

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is that TTF and TCNQ are weighed according to the mass ratio of 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com