Resistance spot welding auxiliary electrode

A technology of resistance spot welding and auxiliary electrodes, applied in the direction of resistance electrode base, electrode characteristics, metal processing, etc., can solve problems such as difficult and easy out-of-tolerance repairs, and achieve the effects of simple operation, strong contact adaptability, and avoiding repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

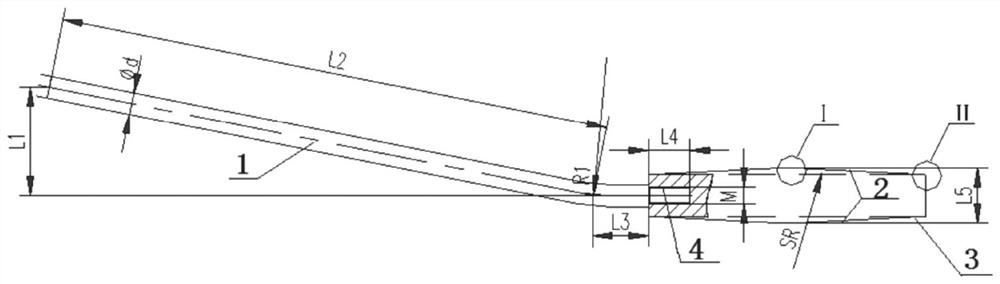

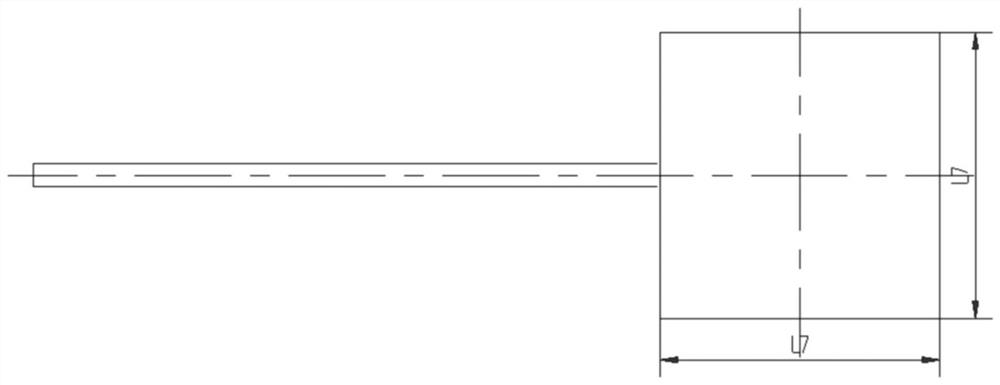

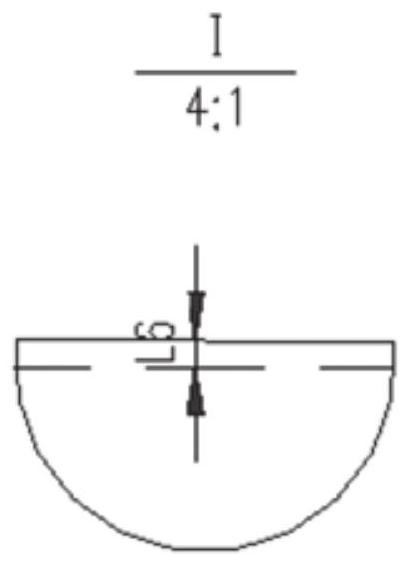

[0048] Such as figure 1 , figure 2 As shown, Embodiment 1 provides an auxiliary electrode for resistance spot welding, including: a plate-shaped electrode body and a gripping portion 1 connected to the plate-shaped electrode body, both sides of the plate-shaped electrode body are spherical structures 2, construction operation Convenience, guaranteed product quality, and improved commercial appearance quality are especially important for non-painted rail transit resistance spot welded structural stainless steel car bodies.

[0049] In this embodiment, the plate-shaped electrode body is a chrome-zirconium copper plate.

[0050] It can be understood that, in some other embodiments, the plate-shaped electrode body can also use a beryllium-nickel-copper plate 3, or a beryllium-cobalt copper plate, or a high-tungsten copper plate, etc., and those skilled in the art can choose according to specific working conditions, here No longer.

[0051] In this embodiment, the chromium-zirc...

Embodiment 2

[0060] Embodiment 2 of the present disclosure provides an auxiliary electrode for resistance spot welding, including: a plate-shaped electrode body and a gripping portion 1 connected to the plate-shaped electrode body. Both sides of the plate-shaped electrode body are curved surface structures, which is convenient for construction and operation , to ensure product quality, and to improve the commercial appearance quality, it is especially important for non-painted rail transit resistance spot welded stainless steel car bodies.

[0061] In this embodiment, the plate-shaped electrode body is a chrome-zirconium copper plate.

[0062] It can be understood that, in some other embodiments, the plate-shaped electrode body can also be a beryllium-nickel-copper plate, or a beryllium-cobalt-copper plate, or a high-tungsten copper plate, etc., and those skilled in the art can choose according to specific working conditions. Let me repeat.

Embodiment 3

[0070] Embodiment 3 of the present disclosure provides an auxiliary electrode for resistance spot welding, including: a plate-shaped electrode body and a gripping portion 1 connected to the plate-shaped electrode body, one side of the plate-shaped electrode body is an arc surface structure, and the other side is a spherical surface Structure, convenient construction and operation, guaranteed product quality, and improved commercial appearance quality are especially important for non-painted rail transit resistance spot welding structural stainless steel car bodies.

[0071] In this embodiment, the plate-shaped electrode body is a chrome-zirconium copper plate.

[0072] It can be understood that, in some other embodiments, the plate-shaped electrode body can also be a beryllium-nickel-copper plate, or a beryllium-cobalt copper plate, or a high-tungsten copper plate, etc., and those skilled in the art can choose according to specific working conditions, which are not mentioned he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com