Preparation method of high-density Y2O3 doped W-Re alloy

A dense and high-density technology, which is applied in the field of preparation of high-density Y2O3 doped W-Re alloys, can solve the problems of block performance impact, easy doping of impurities, etc., and achieve improved grain boundary bonding force and good pinning effect , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the preparation method of the alloy element and rare earth oxide doped tungsten-based composite material is as follows:

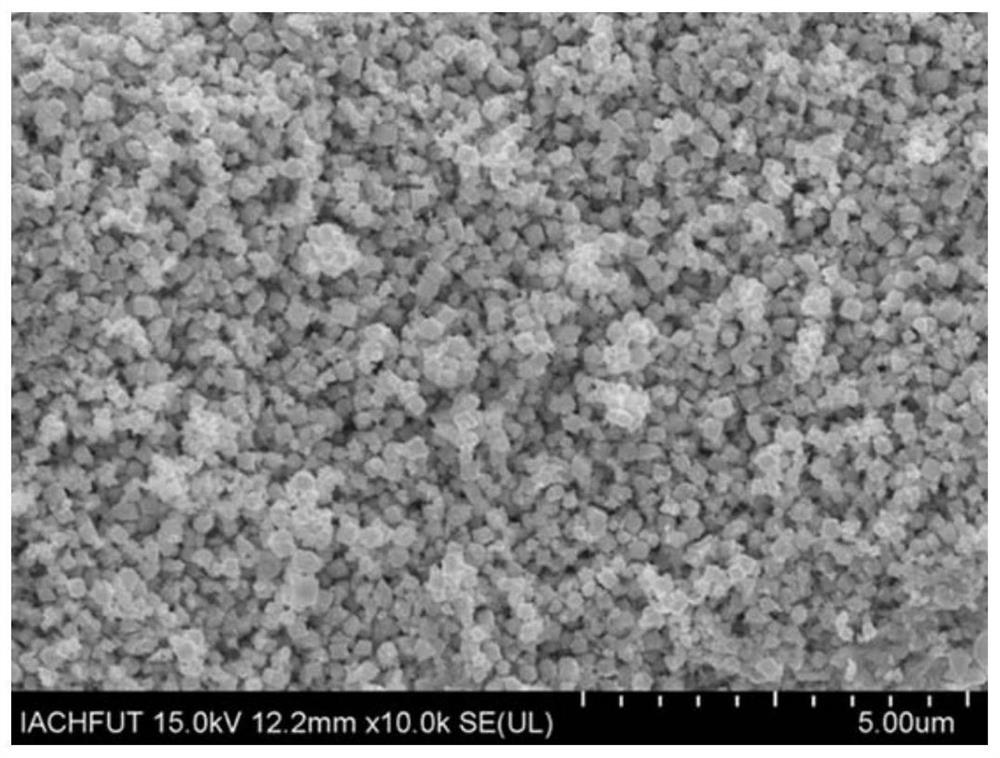

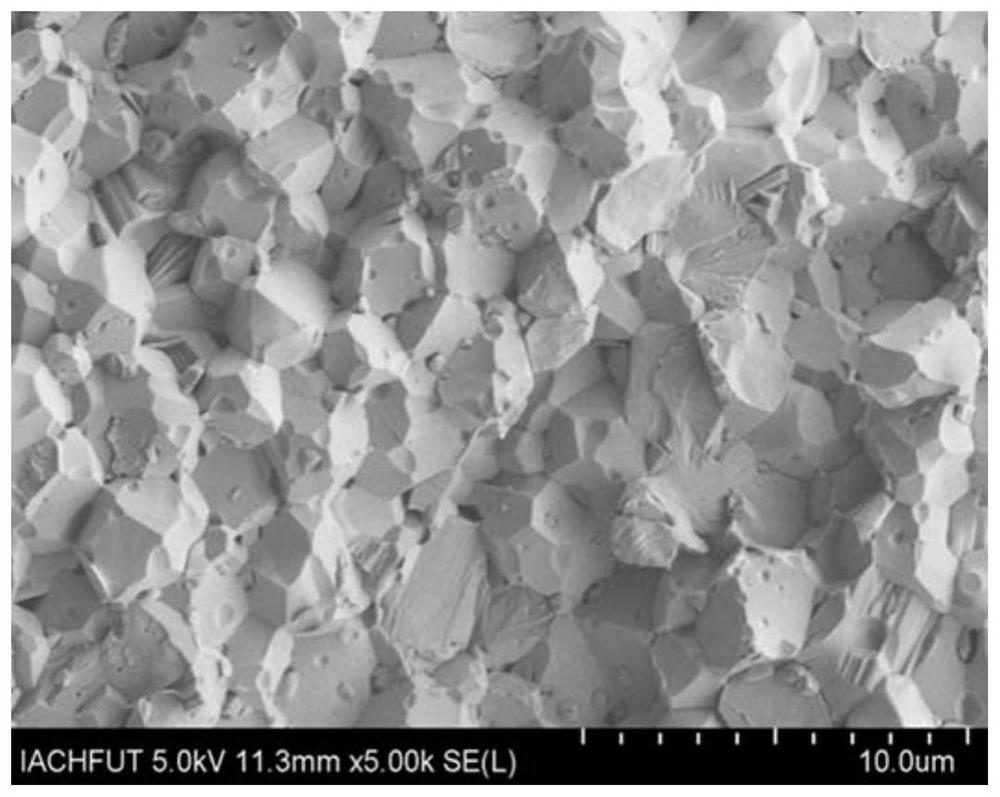

[0020] Step 1: Preparation of precursor powder

[0021] A certain amount of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O, Aladdin, purity ≥ 99.9%), ammonium rhenate (NH 4 ReO 4 , purity ≥ 99.9%) and surfactant triethanolamine oleate (C 16 h 22 N 4 o 3 , purity ≥ 99%) were dissolved in a certain amount of deionized water, and then the three solutions were mixed and stirred evenly; then added ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%) solution dissolved in a certain amount of deionized water Then put it into a magnetic stirrer to heat and stir well, and finally add a certain amount of oxalic acid dihydrate (C 2 h 2 o 4 2H 2 O, analytically pure) as a precipitant, the mixed solution was heated at a constant temperature in a magnetic stirrer at 120°C to evaporate the liquid, and then put into an oven for dry...

Embodiment 2

[0028]In this embodiment, the preparation method of the alloy element and rare earth oxide doped tungsten-based composite material is as follows:

[0029] Step 1: Preparation of precursor powder

[0030] A certain amount of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O, Aladdin, purity ≥ 99.9%), ammonium rhenate (NH 4 ReO 4 , purity ≥ 99.9%) and surfactant triethanolamine oleate (C 16 h 22 N 4 o 3 , purity ≥ 99%) were dissolved in a certain amount of deionized water, and then the three solutions were mixed and stirred evenly; then added ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%) solution dissolved in a certain amount of deionized water Then put it into a magnetic stirrer to heat and stir well, and finally add a certain amount of oxalic acid dihydrate (C 2 h 2 o 4 2H 2 O, analytically pure) as a precipitant, the mixed solution was heated at a constant temperature in a magnetic stirrer at 140°C and evaporated to dryness, and then put into an oven for dr...

Embodiment 3

[0037] In this embodiment, the preparation method of the alloy element and rare earth oxide doped tungsten-based composite material is as follows:

[0038] Step 1: Preparation of precursor powder

[0039] A certain amount of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O, Aladdin, purity ≥ 99.9%), ammonium rhenate (NH 4 ReO 4 , purity ≥ 99.9%) and surfactant triethanolamine oleate (C 16 h 22 N 4 o 3 , purity ≥ 99%) were dissolved in a certain amount of deionized water, and then the three solutions were mixed and stirred evenly; then added ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%) solution dissolved in a certain amount of deionized water Then put it into a magnetic stirrer to heat and stir well, and finally add a certain amount of oxalic acid dihydrate (C 2 h 2 o 4 2H 2 O, analytically pure) as a precipitant, the mixed solution was heated at a constant temperature in a magnetic stirrer at 130 ° C to evaporate the liquid, and then put into an oven for d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com