A kind of iron-manganese-based positive electrode material and its preparation method and application

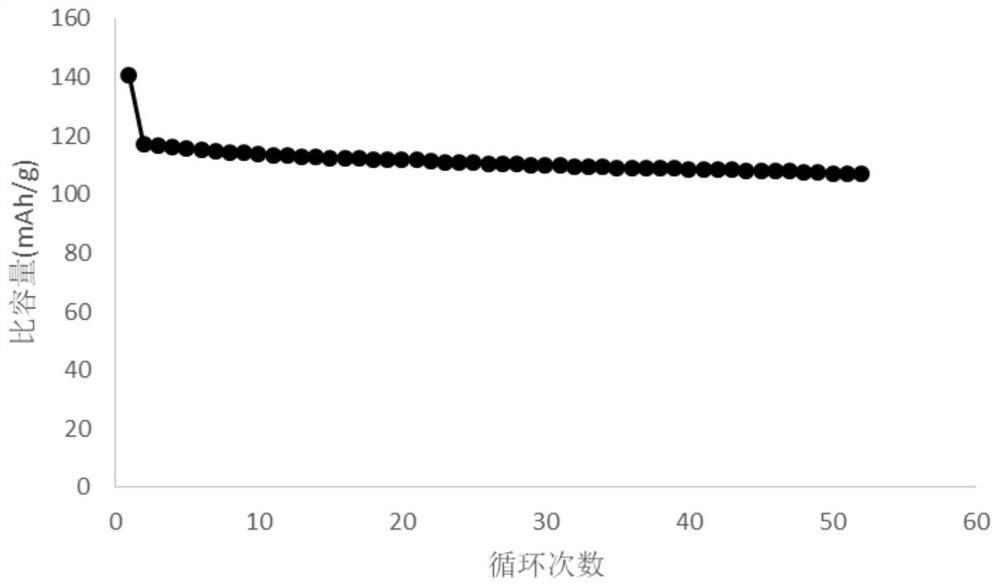

A positive electrode material, iron-manganese-based technology, applied in the field of iron-manganese-based positive electrode materials and their preparation, can solve problems such as poor cycle stability, achieve the effect of low lithium element, stable structure, and ensure cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to a typical implementation of the present application, a method for preparing an iron-manganese-based positive electrode material is provided, the preparation method comprising: step S1, combining an inorganic compound of lithium and Fe x mn y (OH) 2 The precursor is oxidized and sintered to obtain an intermediate product, wherein, 0x mn y (OH) 2 The ratio of the total molar amounts of Fe and Mn in the precursor is 0.1:1 to 0.5:1; step S2, under the condition of nitrogen or the first inert gas atmosphere, the intermediate product is subjected to the second sintering to obtain the iron-manganese-based positive electrode material .

[0027] In the above-mentioned preparation method of the present application, the molar weight and Fe of Li in the inorganic compound of controlling lithium x mn y (OH) 2 The ratio of the total molar amount of Fe and Mn in the precursor is 0.1:1 to 0.5:1, that is, the amount of lithium used is much lower than that of iron and ...

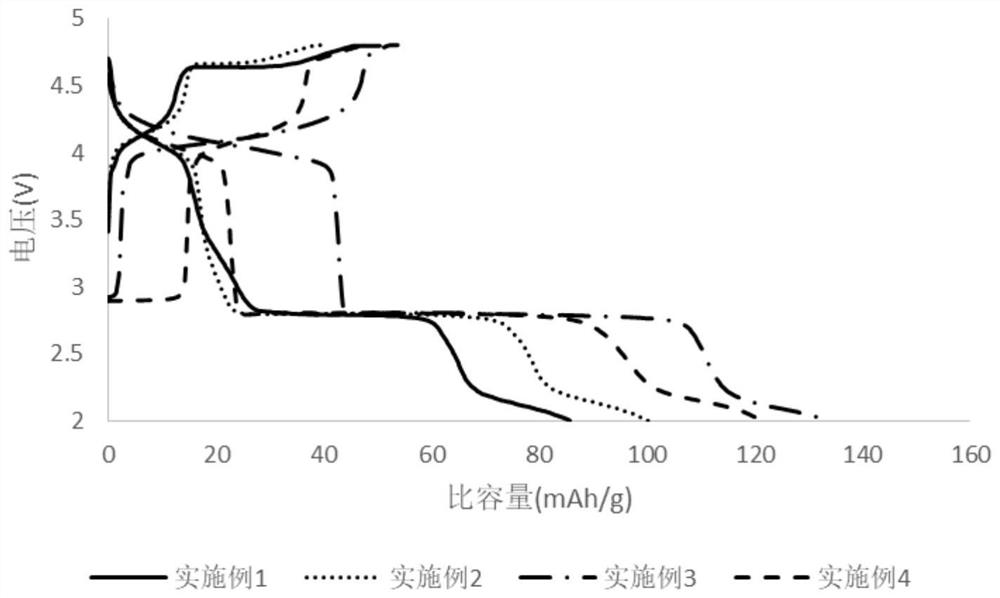

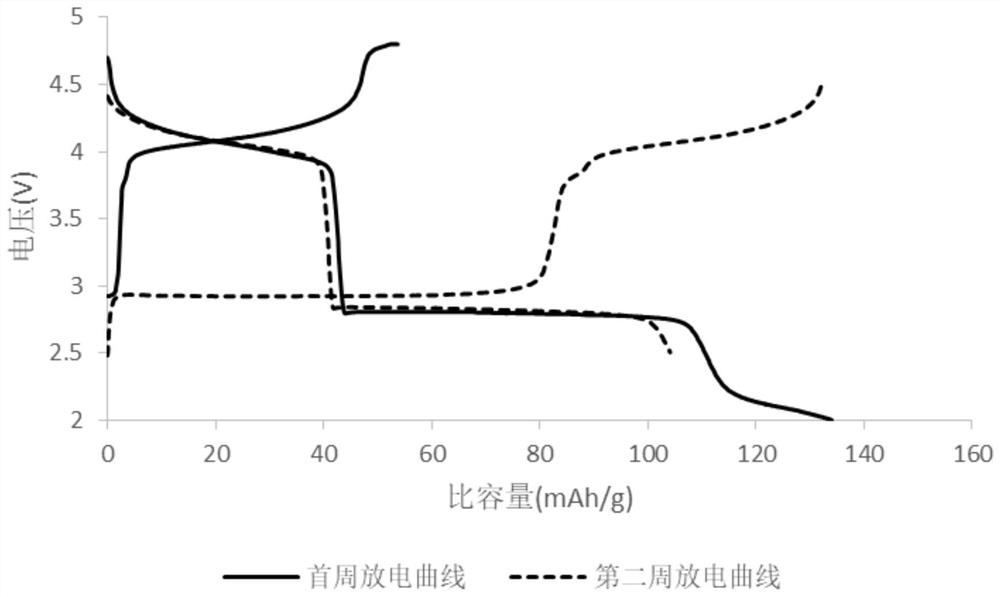

Embodiment 1

[0041] 1) Mix 500g ferrous chloride, 500g manganese acetate and 2000mL water in the reactor, add 300g ammonia complexing agent to the reactor, feed nitrogen into the reactor at a speed of 3L / min, heat the reactor When the dispersion liquid reaches 45°C, add sodium hydroxide solution to the reaction kettle to adjust the pH of the dispersion liquid to 12, and stir the dispersion liquid at 300rpm to carry out coprecipitation reaction. washed, and dried in an oven at 100 °C to obtain Fe 0.5 mn 0.5 (OH) 2 Precursor.

[0042] 2) In a dry environment, 100gFe 0.5 mn 0.5 (OH) 2 Precursor and 4.7g lithium hydroxide (n Li :( Fe +n Mn )=0.1) to be ball milled until uniform.

[0043] 3) Put the uniformly mixed material in a Nabertherm box furnace, feed pure oxygen into the box furnace at a flow rate of 2L / min, and heat it up to 600°C at a rate of 2°C / min, then keep it warm for 5h , to obtain intermediate products.

[0044] 4) Stop feeding pure oxygen into the box-type furnace, a...

Embodiment 2

[0046] The difference with Example 1 is that in step 2) 100gFe 0.5 mn 0.5 (OH) 2 Precursor and 14.1g lithium hydroxide (n Li :( Fe +n Mn )=0.3) to carry out ball milling and mix until uniform, after step 4), finally obtain Li 0.3 Fe 0.5 mn 0.5o 2 Fe-Mn based cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com