Preparation method of chitosan oligosaccharide

A technology of oligochitosan and chitosan, which is applied in the field of bioengineering, achieves the effects of high yield, high biological activity and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of chitosan oligosaccharide, comprises the steps:

[0033] (1) Preparation of chitosan solution: take 1g chitosan, dissolve in 50mL water and stir fully to make chitosan evenly dispersed in water, add hydrochloric acid to make hydrochloric acid content 0.5wt%, adjust with 2wt% sodium hydroxide pH to 5.0, stir until chitosan is completely dissolved.

[0034] (2) Enzymolysis: add chitosan enzyme to the above chitosan solution, the amount of enzyme added is 400U, the enzymolysis rotation speed is 200rpm, the temperature is 45°C, and the time is 8-10h. After the reaction is over, heat up to 85°C to inactivate the enzyme for 10-30 minutes.

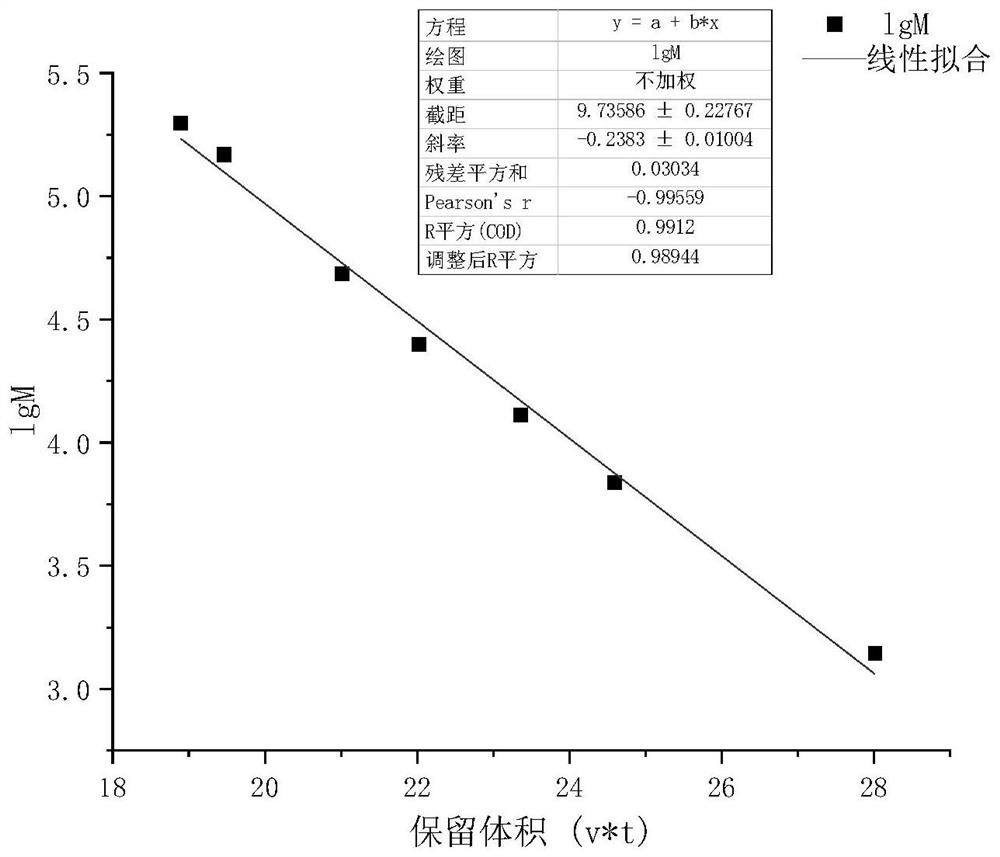

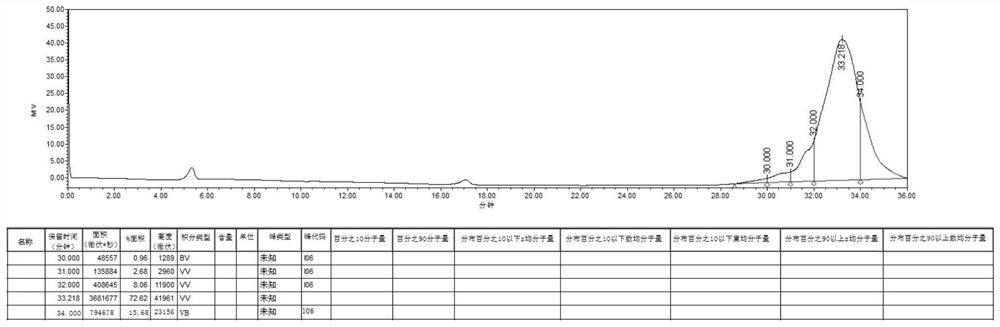

[0035] (3) Separation and purification: use the microfiltration device to pass the above enzymatic hydrolysis solution through the 0.45 μm and 0.22 μm filter membranes of the water system, and then pass the above enzymatic hydrolysis solution through 5.0×10 4 Da, 1.0×10 4 Da, 3.0×10 3 Large plate ultrafil...

Embodiment 2

[0038] A kind of preparation method of chitosan oligosaccharide, comprises the steps:

[0039] (1) Preparation of chitosan solution: take 1g chitosan, dissolve in 60mL water and stir fully to make chitosan evenly dispersed in water, add acetic acid to make the acetic acid content 1wt%, adjust pH with 10wt% sodium hydroxide To 5.5, stir until the chitosan is completely dissolved.

[0040] (2) Enzymolysis: add chitosan enzyme to the above chitosan solution, the amount of enzyme added is 600U, the enzymolysis rotation speed is 150rpm, the temperature is 55°C, and the time is 4-6h. After the reaction is over, heat up to 85°C to inactivate the enzyme for 10-30 minutes.

[0041] (3) Separation and purification: use the microfiltration device to pass the above enzymatic hydrolysis solution through the 0.45 μm and 0.22 μm filter membranes of the water system, and then pass the above enzymatic hydrolysis solution through 5.0×10 4 Da, 1.0×10 4 Da, 3.0×10 3 Large plate ultrafiltratio...

Embodiment 3

[0044] A kind of preparation method of chitosan oligosaccharide, comprises the steps:

[0045] (1) Preparation of chitosan solution: take 1g chitosan, dissolve in 70mL water and stir fully to make chitosan evenly dispersed in water, add phosphoric acid to make phosphoric acid content 2wt%, adjust pH with 5wt% sodium hydroxide To 6, stir until the chitosan is completely dissolved.

[0046] (2) Enzymolysis: add chitosan enzyme to the above chitosan solution, the amount of enzyme added is 700U, the enzymolysis rotation speed is 200rpm, the temperature is 55°C, and the time is 3-5h. After the reaction is over, heat up to 85°C to inactivate the enzyme for 10-30 minutes.

[0047](3) Separation and purification: use the microfiltration device to pass the above enzymatic hydrolysis solution through the 0.45 μm and 0.22 μm filter membranes of the water system, and then pass the above enzymatic hydrolysis solution through 5.0×10 4 Da, 1.0×10 4 Da, 3.0×10 3 Large plate ultrafiltratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com