Solar-driven seawater lithium extraction system and preparation method thereof

A technology of solar energy and seawater, applied in the field of solar-driven lithium extraction system from seawater and its preparation, can solve the problems of high cost of solid electrolyte film, the need for sealing the system, unfavorable application, etc., and achieves feasibility, practicability, simple scientific principle, and easy popularization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

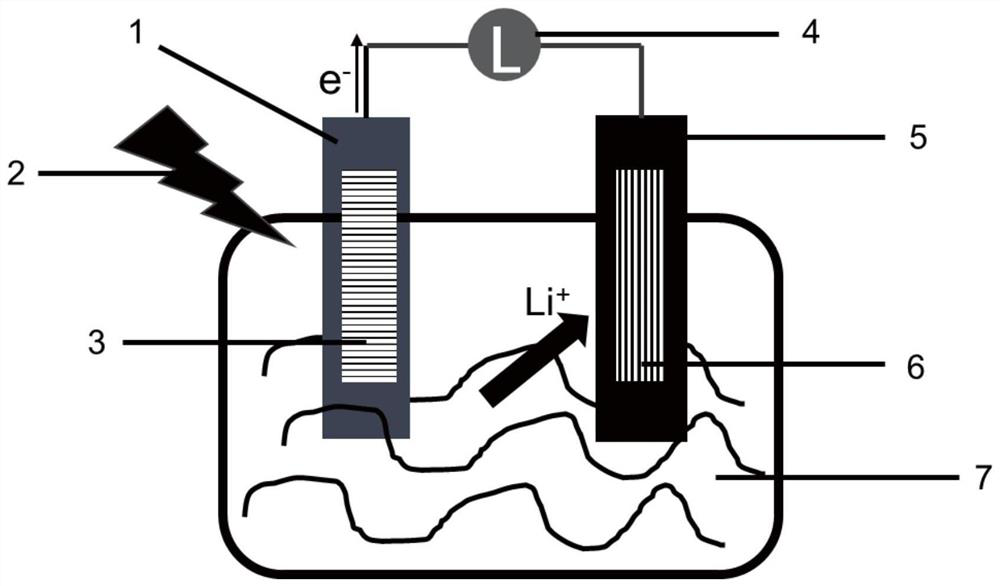

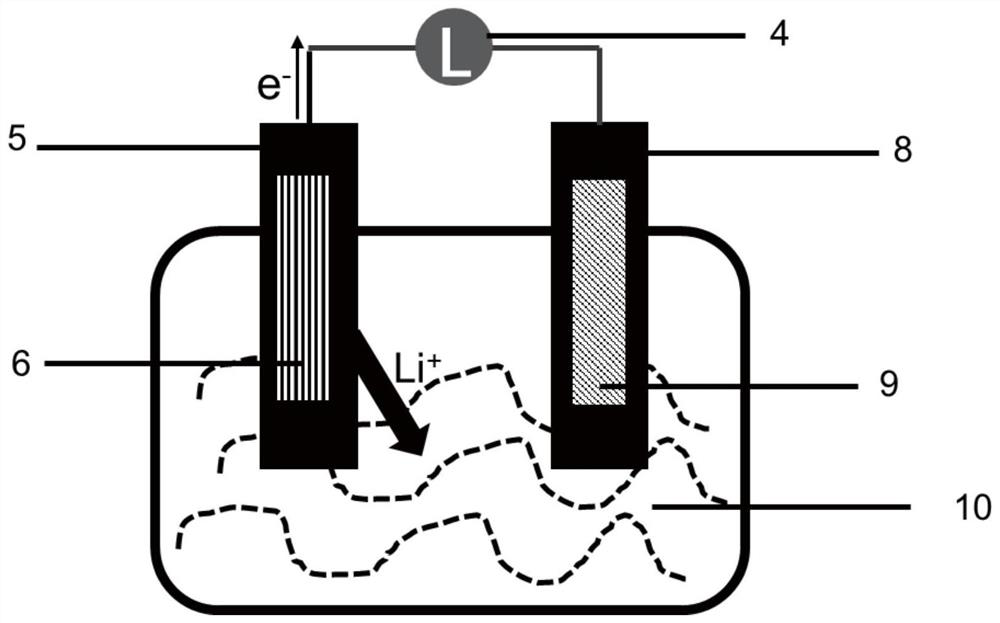

[0060] The embodiment of the present invention provides a preparation method of a solar-driven seawater lithium extraction system, the method comprising the following specific steps:

[0061] Step 1: Selection and preparation of cathode

[0062] A1: Selection of lithium enrichment materials

[0063] The electrode material with specificity for lithium ion selection is selected as the cathode material.

[0064] The crystal with specific storage sites for Li ion selection is: LiFePO 4 , LiMn 2 o 4 , Li 1-x mn 2 o 4 , λ-MnO 2 、Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 、Ni 0.5 mn 1.5 o 4 And after coating through structural optimization, such as LiFePO 4 @TiO 2 、LiFePO 4 @SiO 2 、LiFePO 4 @PDA et al.

[0065] A2: Preparation of cathode

[0066] The cathode is prepared by spin coating or dipping and pulling;

[0067] i) Coating: The lithium-enriched material, the conductive agent, and the binder are ground according to the ratio under the action of the solvent for 10 to 30 minut...

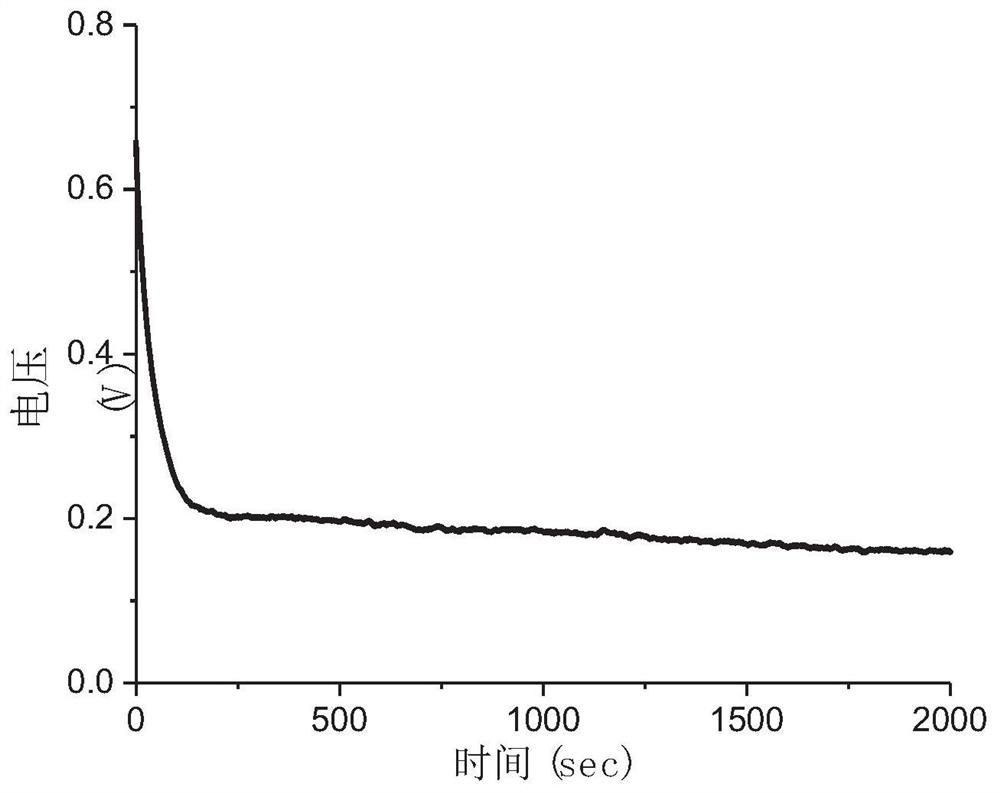

Embodiment 1

[0106] Spin coating + substrate growth

[0107] The cathode material selected in this embodiment is that the molecular formula is LiFePO 4 ; The photoanode material is titanium dioxide N-type semiconductor, and its molecular formula is TiO 2 ; The electrolyte is natural seawater.

[0108] Step 1: LiFePO 4 Preparation of lithium-enriched cathode materials

[0109] Equivalent amount (0.05) of FeCl 2 h 2 O, LiCO 3 and H 3 PO 4 In order to serve as Fe source, Li source, and P source, add to 200ml of absolute ethanol in sequence, after supernatant dispersion, stir at room temperature (25°C), after the sol is completely transformed into a gray gel, after standing at room temperature for 12 hours, transfer the product To 80 ℃ blast drying oven, dry for 12 hours. Then the dried product was ground into powder in an agate mortar and transferred to a porcelain boat, and calcined at 500°C for 10 hours at a heating rate of 5°C / min under the protection of a nitrogen atmosphere in a...

Embodiment 2

[0119] Spin coating + anodizing method

[0120] The cathode material selected in this embodiment is that the molecular formula is LiFePO 4 ; The photoanode material is titanium dioxide N-type semiconductor, and its molecular formula is TiO 2 ; The electrolyte is natural seawater.

[0121] Step 1: LiFePO 4 Preparation of lithium-enriched cathode materials

[0122] Equivalent amount (0.05) of FeCl 2 h 2 O, LiCO 3 and H 3 PO 4 In order to serve as Fe source, Li source, and P source, add to 200ml of absolute ethanol in sequence, after supernatant dispersion, stir at room temperature (25°C), after the sol is completely transformed into a gray gel, after standing at room temperature for 12 hours, transfer the product To 80 ℃ blast drying oven, dry for 12 hours. Then the dried product was ground into powder in an agate mortar and transferred to a porcelain boat, and calcined at 500°C for 10 hours at a heating rate of 5°C / min under the protection of a nitrogen atmosphere in a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com