Nanofiber as well as preparation method and application thereof

A technology of nanofiber and cellulose acetate, which is applied in the field of nanomaterials, can solve the problems of slow detection speed and low detection sensitivity, and achieve the effects of shortening detection time, high detection sensitivity and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

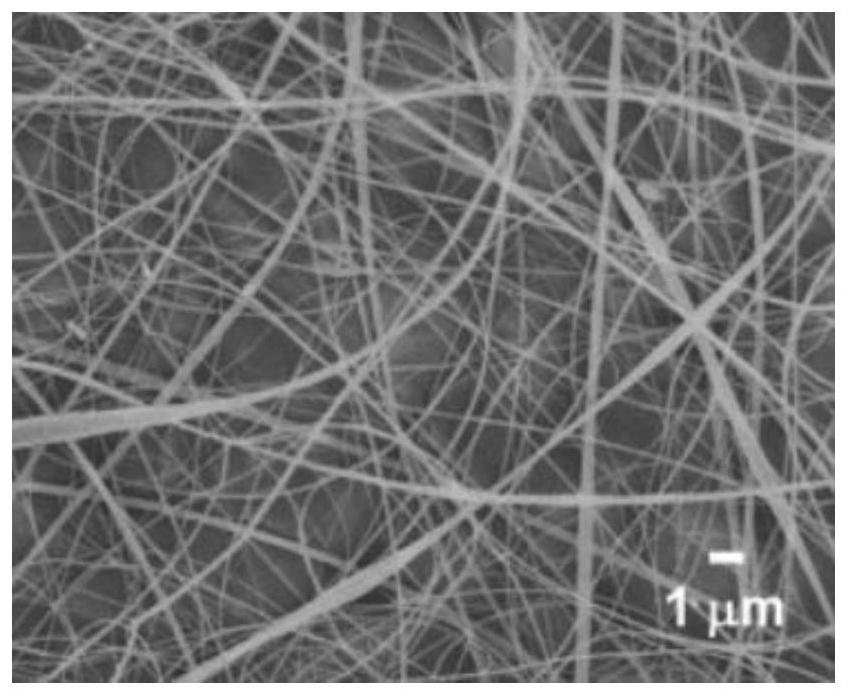

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of nanofiber

[0038] A kind of nanofiber, the raw material component of preparing nanofiber comprises: 0.3g cellulose acetate, 0.1g p-hydroxybenzoic acid and 3mL solvent (solvent is made of acetone and N,N-dimethylformamide according to volume ratio is 2:1 proportion composition).

[0039] The preparation method of above-mentioned nano fiber, comprises the following steps:

[0040] Mix cellulose acetate, p-hydroxybenzoic acid and solvent, heat and stir, the temperature of heating and stirring is 100°C, the stirring speed of heating and stirring is 1000 rpm, and the time of heating and stirring is 1 hour, and the electrospinning solution is prepared, and then The electrospinning equipment is used for spinning. The working parameters of the electrospinning equipment are: the needle tip voltage is 20kV, the receiving plate voltage is -1kv, the receiving distance is 20cm, and the injection rate of the electrospinning solution is 0.5mL / h. fib...

Embodiment 2

[0042] Embodiment 2: the preparation of nanofiber

[0043] A kind of nanofiber, the raw material component of preparing nanofiber comprises: 0.2g cellulose acetate, 0.1g p-hydroxybenzoic acid and 3mL solvent (solvent is by volume ratio 1:1 by acetone and N,N-dimethylformamide proportion composition).

[0044] The preparation method of above-mentioned nano fiber, comprises the following steps:

[0045] Mix cellulose acetate, p-hydroxybenzoic acid and solvent, heat and stir, the temperature of heating and stirring is 105°C, the stirring speed of heating and stirring is 1000 rpm, and the time of heating and stirring is 1.5 hours, and the electrospinning solution is obtained, and then The electrospinning equipment is used for spinning. The working parameters of the electrospinning equipment are: the needle tip voltage is 22kV, the receiving plate voltage is -1.5kv, the receiving distance is 18cm, and the injection rate of the electrospinning solution is 0.4mL / h. Nanofibers.

Embodiment 3

[0046] Embodiment 3: the preparation of nanofiber

[0047] A kind of nanofiber, the raw material component of preparing nanofiber comprises: 0.4g cellulose acetate, 0.1g p-hydroxybenzoic acid and 4mL solvent (solvent is made of acetone and N,N-dimethylformamide according to volume ratio is 2:1 proportion composition).

[0048] The preparation method of above-mentioned nano fiber, comprises the following steps:

[0049]Mix cellulose acetate, p-hydroxybenzoic acid and solvent, heat and stir, the temperature of heating and stirring is 95°C, the stirring speed of heating and stirring is 1100 rpm, and the time of heating and stirring is 1 hour, and the electrospinning solution is prepared, and then The electrospinning equipment is used for spinning. The working parameters of the electrospinning equipment are: the needle tip voltage is 20kV, the receiving plate voltage is -1kv, the receiving distance is 22cm, and the injection rate of the electrospinning solution is 0.5mL / h. fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com