Coconut fiber brake pad and preparation method thereof

A technology of coconut fiber and brake pads, which is applied in the field of coconut fiber brake pads and its preparation, to achieve the effect of adding new ways and solving the shortage of natural fiber demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

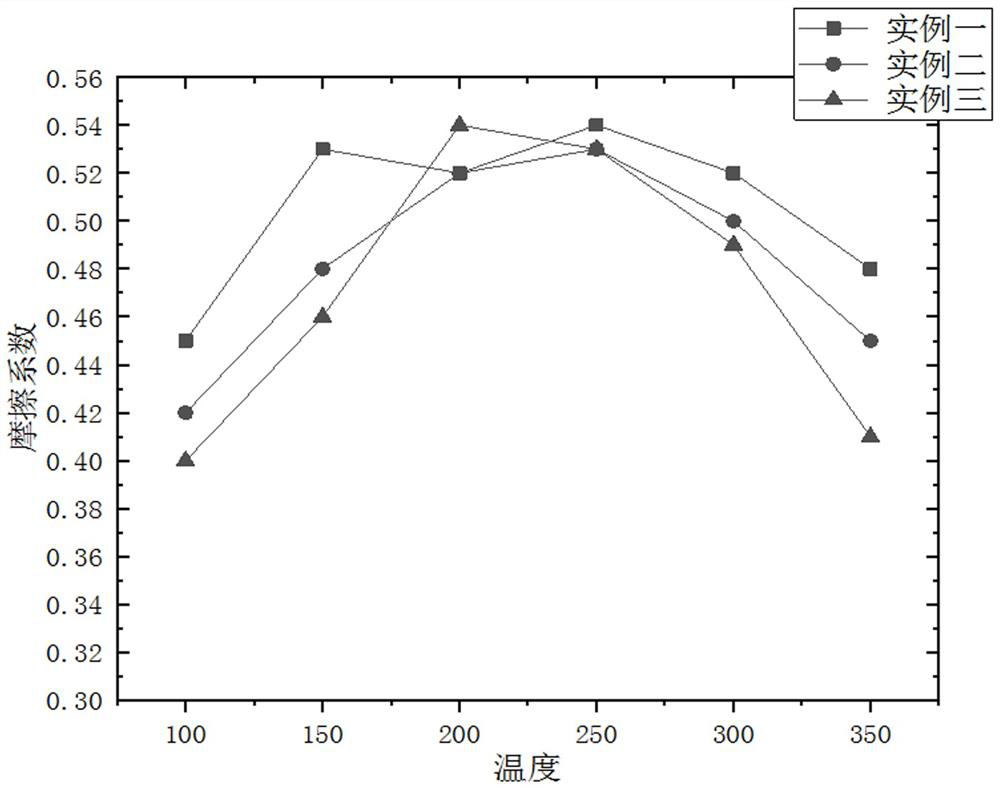

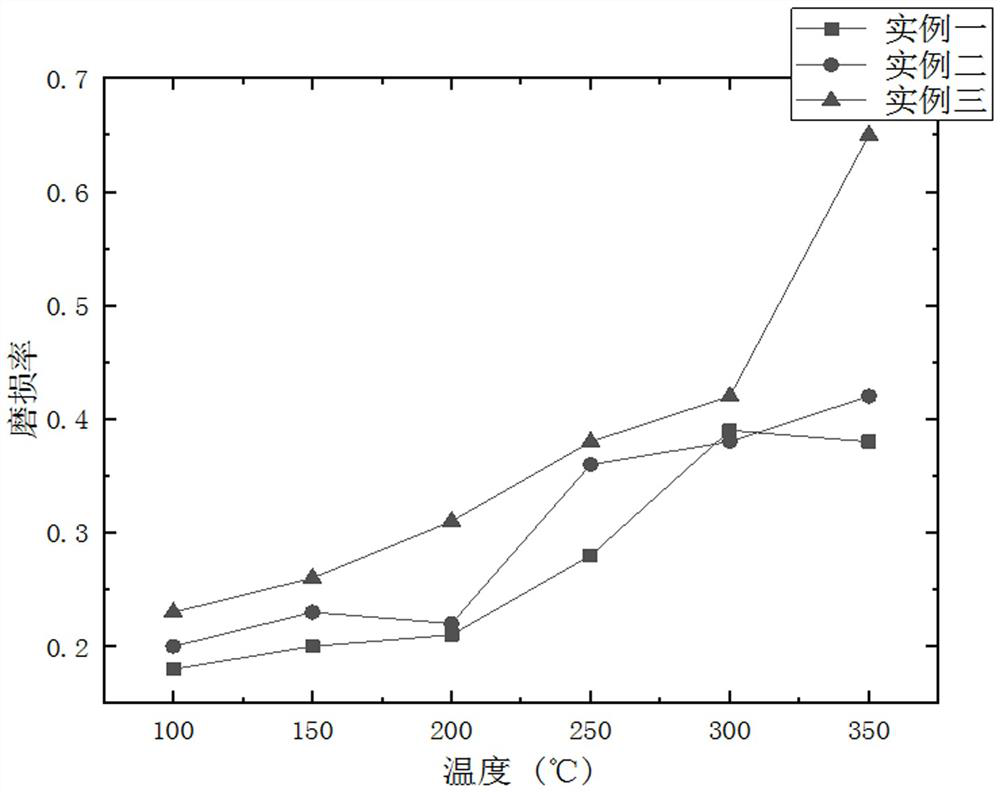

[0027] A coconut fiber brake pad, comprising the following components in percentage by weight: 20 parts of resin, 24 parts of barite, 15 parts of aluminum oxide, 7 parts of graphite, 5 parts of rubber powder, 9 parts of coconut fiber, and 10 parts of lanthanum oxide , 10 parts of ceramic fiber.

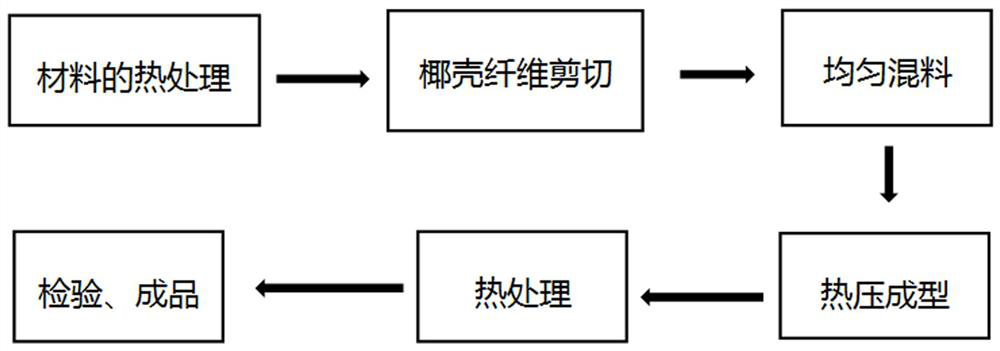

[0028] The preparation method of described coir fiber brake pad is as follows:

[0029] (1) Drying of raw materials: Dry phenolic resin at 60°C for half an hour, coconut fiber at 100°C for one and a half hours, lanthanum oxide at 220°C for two hours, rubber powder at 60°C for half an hour Hours, other components were dried at 110°C for one hour.

[0030] (2) Cutting: Use a fiber cutter to cut the coconut shell fiber to obtain coconut shell fiber with a suitable length.

[0031] (3) Mixing: Mix the dried raw materials according to the experimental design formula and put them into a BL25C33 mixer with multiple sets of high-speed rotary knives for 1-2 minutes to obtain a uniform powder...

Embodiment 2

[0036] A coconut fiber brake pad, comprising the following components in percentage by weight: 20 parts of resin, 22 parts of barite, 15 parts of aluminum oxide, 9 parts of graphite, 5 parts of rubber powder, 7 parts of coconut fiber, and 12 parts of lanthanum oxide , 10 parts of ceramic fiber.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] A kind of application coconut shell fiber brake pad, comprises the following components of weight percent: 20 parts of resin, 20 parts of barite, 15 parts of aluminum oxide, 11 parts of graphite, 5 parts of rubber powder, 5 parts of coconut shell fiber, 14 parts of lanthanum oxide parts, ceramic fiber 10 parts.

[0040] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com