Preparation method of graphene oxide skeleton composite membrane

A graphene skeleton, composite membrane technology, applied in chemical instruments and methods, separation methods, membrane technology and other directions, can solve the problems of limited adjustment of graphene oxide layer spacing, and achieve flexible adjustment of graphene layer spacing, simple method, high performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

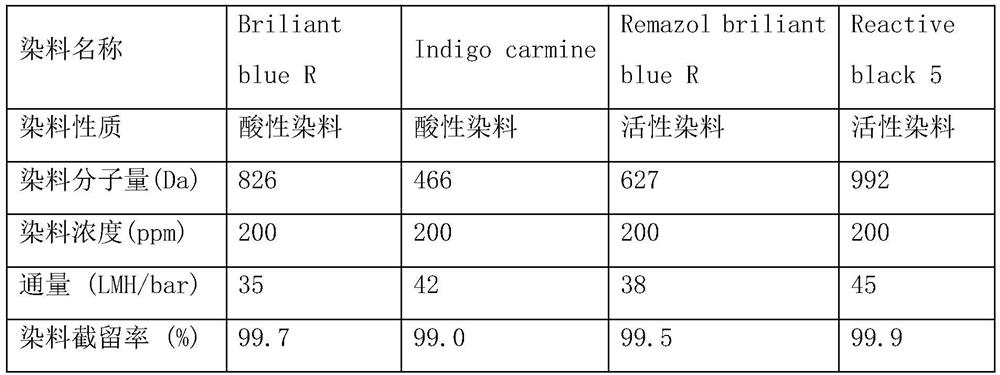

Embodiment 1

[0035] A kind of preparation method of graphene oxide framework composite film, its step comprises,

[0036] S1: Prepare graphene oxide suspension solution by Hummber method. The XY axis size of graphene oxide is 0.1-100 microns, the optimal size is 0.5-10 microns, and the Z-axis size is 1-1.5 nanometers. The concentration of graphene oxide suspension solution 0.5%;

[0037] S2: Synthesis of organometallic framework (MOF) nanoparticles with functional groups,

[0038] S21: Add 0.08 g of zirconium chloride, 0.062 g of aminoterephthalic acid and 0.7 ml of acetic acid into 20 ml of dimethylformamide solution;

[0039] S22: After mixing the above solution evenly, heat it to the set temperature (70-75°C) to react for a certain period of time, and control the particle size of the MOF nanoparticles by controlling the reaction time and temperature, and control the average particle size of the MOF nanoparticles to be 5 ±0.5nm;

[0040] S23: centrifuging the reacted solution to obtai...

Embodiment 2

[0061] A kind of preparation method of graphene oxide framework composite film, its step comprises,

[0062] S1: Prepare graphene oxide suspension solution by Hummber method. The XY axis size of graphene oxide is 0.1-100 microns, the optimal size is 0.5-10 microns, and the Z-axis size is 1-1.5 nanometers. The concentration of graphene oxide suspension solution 0.5%;

[0063] S2: Synthesis of organometallic framework (MOF) nanoparticles with functional groups,

[0064] S21: Add 0.08 g of zirconium chloride, 0.062 g of aminoterephthalic acid and 0.7 ml of acetic acid into 20 ml of dimethylformamide solution;

[0065] S22: After mixing the above solution evenly, heat it to a set temperature (120-125°C) and react for a certain period of time, and control the particle size of MOF nanoparticles by controlling the reaction time and temperature, and control the average particle size of MOF nanoparticles to 40 ~50nm;

[0066] S23: centrifuging the reacted solution to obtain MOF nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com