Concrete curing agent and preparation process thereof

A concrete curing agent and a preparation process technology, applied in the field of building materials, can solve the problems of reducing the obtaining rate of the concrete curing agent, affecting the effect of the floor, poor durability, etc., and achieving the effects of increasing hardness, reducing dosage, and increasing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A concrete curing agent, consisting of the following raw materials in parts by weight: 40 parts of lithium silicate, 10 parts of silane coupling agent, 6 parts of nano-titanium dioxide, 10 parts of modified water reducer, 10 parts of expansion agent and 50 parts of water;

[0039] The concrete curing agent is made by the following method:

[0040] Step 1. Mix and crush lithium silicate and nano-titanium dioxide, pass through a 60-mesh sieve, and then send the mixture to a ball mill for ball milling until a mixture with a fineness of 400 mesh is formed to obtain a mixture A;

[0041] Step 2: Pour the silane coupling agent, modified water reducer, and expansion agent into the mixer together, and stir for 30 minutes at a temperature of 32 degrees Celsius and a rotation speed of 600 rpm to obtain a mixed solution B;

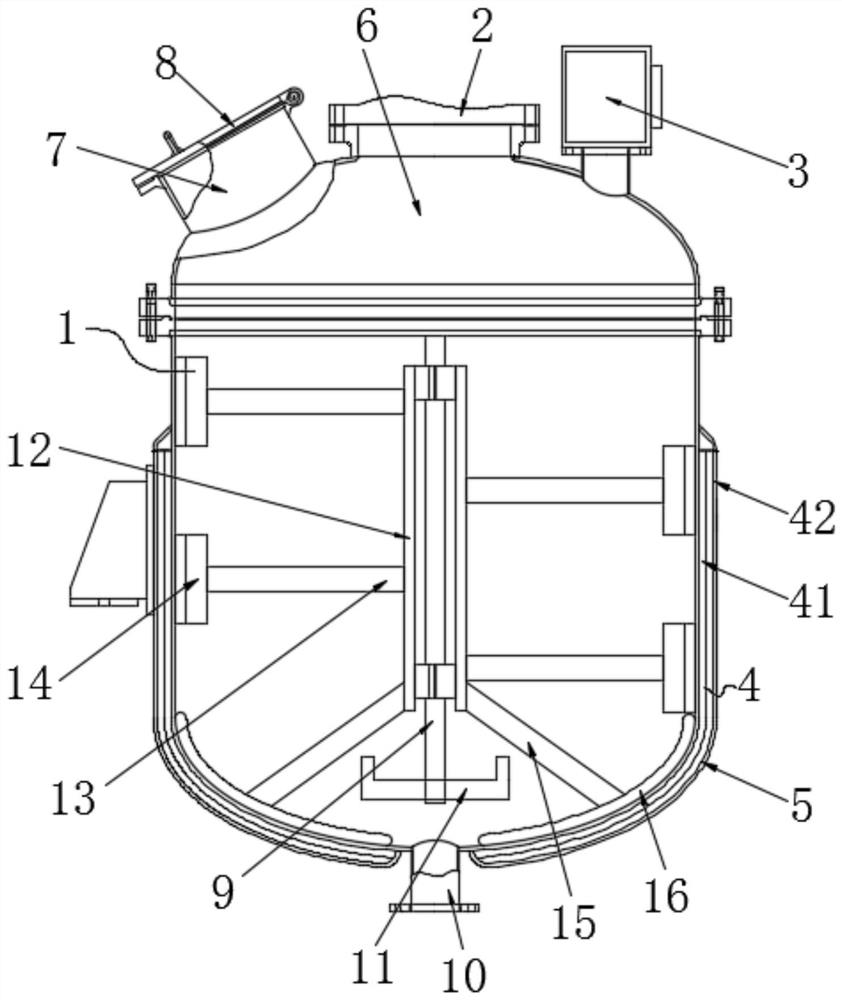

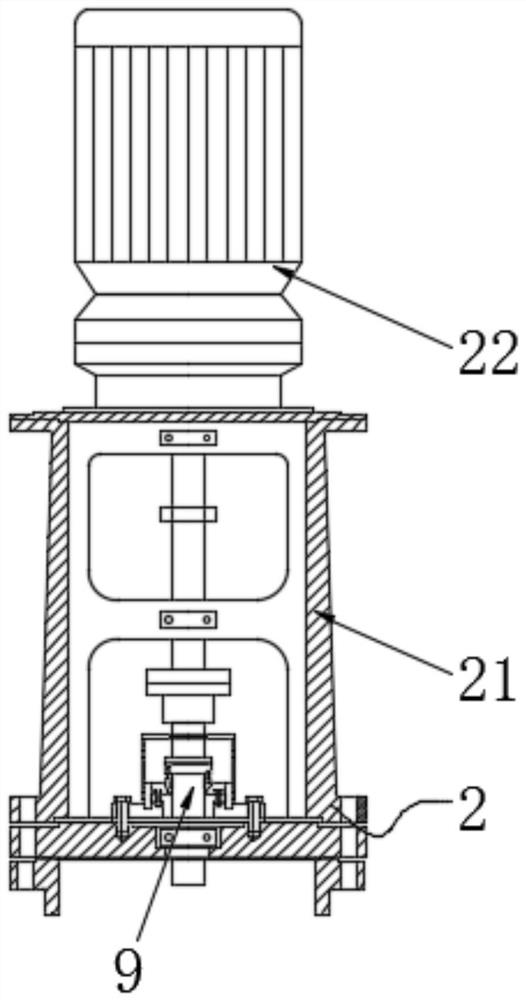

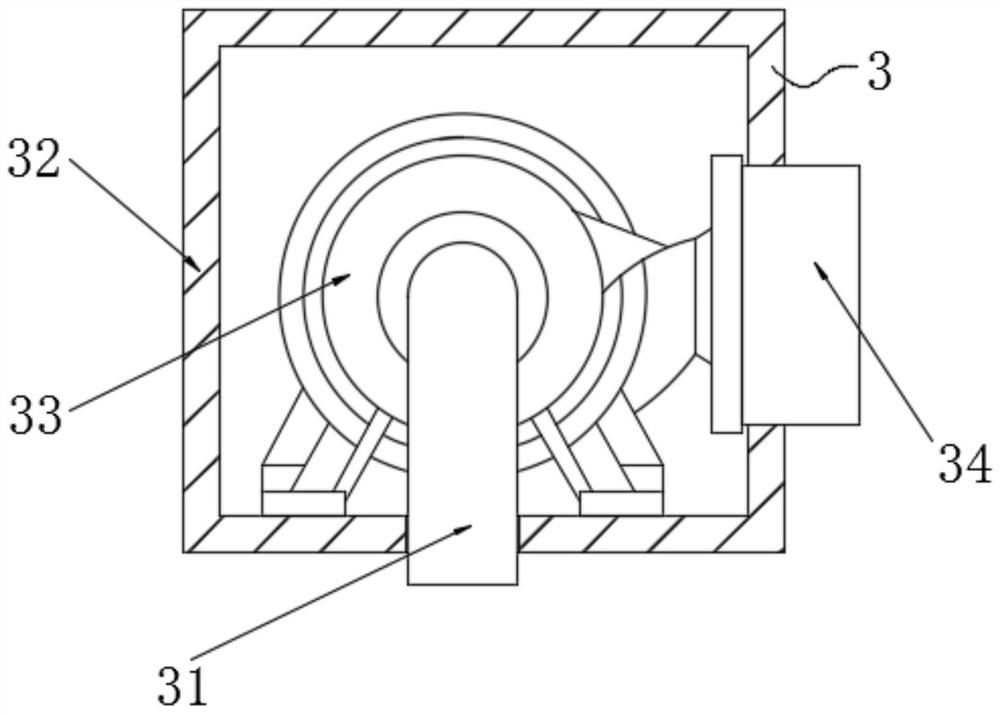

[0042] Step 3, pass the mixture A and the mixture B into the reaction kettle 5 together, open the sealing cover 8, the mixture A and the mixture B enter the i...

Embodiment 2

[0050] A concrete curing agent, consisting of the following raw materials in parts by weight: 60 parts of lithium silicate, 20 parts of silane coupling agent, 12 parts of nano-titanium dioxide, 30 parts of modified water reducer, 20 parts of expansion agent and 80 parts of water;

[0051] The concrete curing agent is made by the following method:

[0052] Step 1. Mix and crush lithium silicate and nano-titanium dioxide, pass through a 60-mesh sieve, and then send the mixture to a ball mill for ball milling until a mixture with a fineness of 400 mesh is formed to obtain a mixture A;

[0053] Step 2: Pour the silane coupling agent, modified water reducer, and expansion agent into the mixer together, and stir for 30 minutes at a temperature of 38 degrees Celsius and a rotation speed of 1200 rpm to obtain a mixed solution B;

[0054] Step 3, pass the mixture A and the mixture B into the reaction kettle 5 together, open the sealing cover 8, the mixture A and the mixture B enter the...

Embodiment 3

[0062] A concrete curing agent, consisting of the following raw materials in parts by weight: 50 parts of lithium silicate, 15 parts of silane coupling agent, 9 parts of nano-titanium dioxide, 20 parts of modified water reducer, 15 parts of expansion agent and 65 parts of water;

[0063] The concrete curing agent is made by the following method:

[0064] Step 1. Mix and crush lithium silicate and nano-titanium dioxide, pass through a 60-mesh sieve, and then send the mixture to a ball mill for ball milling until a mixture with a fineness of 400 mesh is formed to obtain a mixture A;

[0065] Step 2: Pour the silane coupling agent, modified water reducer, and expansion agent into the mixer together, and stir for 30 minutes at a temperature of 35 degrees Celsius and a rotation speed of 900 rpm to obtain a mixed solution B;

[0066] Step 3, pass the mixture A and the mixture B into the reaction kettle 5 together, open the sealing cover 8, the mixture A and the mixture B enter the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com