Preparation and application of covalent cross-linked polyfluoro sulfonated polyimide proton exchange membrane

A technology of polyfluorinated sulfonated polyimide and sulfonated polyimide, applied in the field of battery separators, can solve the problem of incompatibility between functional monomers and sulfonated polyimide, and small improvement in chemical stability of ion crosslinking , It is difficult to improve the stability of the diaphragm to achieve the effect of improving chemical stability, chemical stability and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

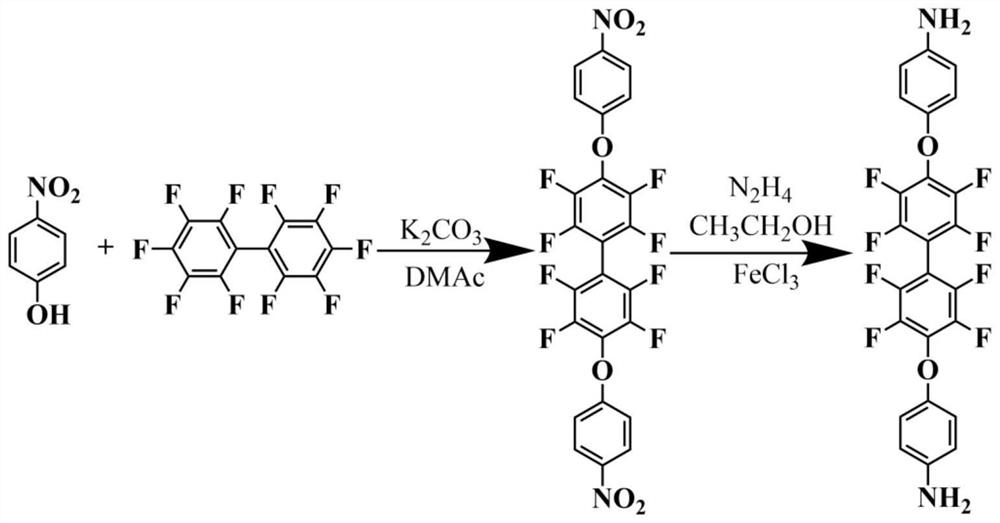

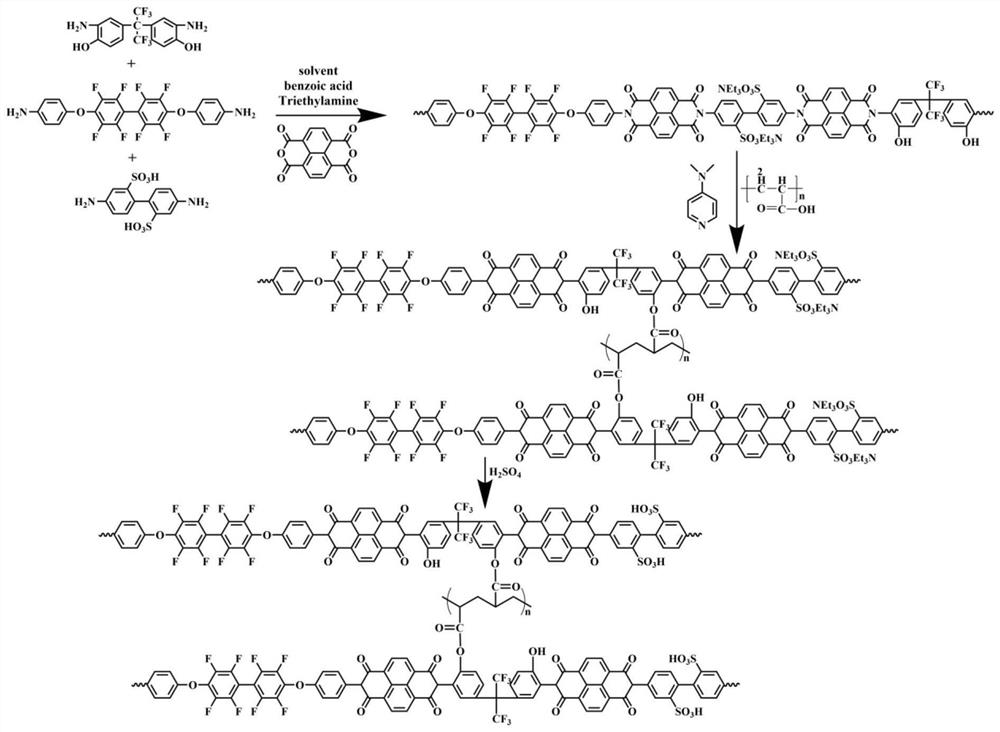

[0043] A method for covalent cross-linking polyfluorulfonated polyimide proton exchange membrane, which is:

[0044] Step 1, under nitrogen protection, 2,2'-sulfonate, bishenolate 4 mmol, triethylamine 4mmol, amphorin, 70 mL, temperature rise to 60 ° C, stirring to completely Dissolve; 4,4 '- (1,1' double (4-aminophenoxy)) octophenyl 2 mmol, 2,2-bis (3-amino-4-hydroxybenzene) was added to 250 ml of tri-necked flask. Base) hexafluoropropane 2 mmol, continued to stir until completely dissolve; 1,4,5,8-naphthalate dianhydride 8 mmol, benzoic acid 16 mmol, stirred to 80 ° C, stirred at 80 ° C for 4. 50 ° C, and stirred to 80 ° C for stirring to 80 ° C for 1,4,5,8-naphthallic dianhydride. The temperature was warmed to 180 ° C, the reaction was 18 h; the reaction system was cooled to 90 ° C or less, and 15 ml of meludes were added to 250 ml of three-necked flask, and the system continued to cool down until 50 ° C; the reaction system was poured into 200 ml of precipitant acetone. To obt...

Embodiment 2

[0051] A method for covalent cross-linking polyfluorulfonated polyimide proton exchange membrane, which is:

[0052] Step 1, under nitrogen protection, 2,2'-sulfonate, bishenolate 4 mmol, triethylamine 4mmol, amphorin, 70 mL, temperature rise to 60 ° C, stirring to completely Dissolve; 4,4 '- (1,1' double (4-aminophenoxy)) octophenyl 2 mmol, 2,2-bis (3-amino-4-hydroxybenzene) was added to 250 ml of tri-necked flask. Based) Slurfluoropropane 2 mmol, continued to stir until completely dissolved; 1,4,5,8-naphthalate diallorhydride 8 mmol, benzoic acid was added to 80 ° C for 1,4,5,8-naphthallonic dianhydride. Then he was warmed to 180 ° C, and the reaction was 18 h. After the reaction system was cooled to 90 ° C or less, 15 ml of meptes were added to a 250 mL of three-necked flask, and the system continued to cool down until 50 ° C. The reaction system was poured into 200 ml of precipitant acetone, resulting in a solid, filtered, dried, and then obtained, to obtain a polyvilulfonated...

Embodiment 3

[0059] A method for covalent cross-linking polyfluorulfonated polyimide proton exchange membrane, which is:

[0060] Step 1, under nitrogen protection, 2,2'-sulfonate, bishenolate 4 mmol, triethylamine 4mmol, amphorin, 70 mL, temperature rise to 60 ° C, stirring to completely Dissolve; 4,4 '- (1,1' double (4-aminophenoxy)) octophenyl 2 mmol, 2,2-bis (3-amino-4-hydroxybenzene) was added to 250 ml of tri-necked flask. Based) Slurfluoropropane 2 mmol, continued to stir until completely dissolved; 1,4,5,8-naphthalate diallorhydride 8 mmol, benzoic acid was added to 80 ° C for 1,4,5,8-naphthallonic dianhydride. Then he was warmed to 180 ° C, and the reaction was 18 h. After the reaction system was cooled to 90 ° C or less, 15 ml of meptes were added to a 250 mL of three-necked flask, and the system continued to cool down until 50 ° C. The reaction system was poured into 200 ml of precipitant acetone, resulting in a solid, filtered, dried, and then obtained, to obtain a polyvilulfonated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com