Making method of summer and autumn white tea

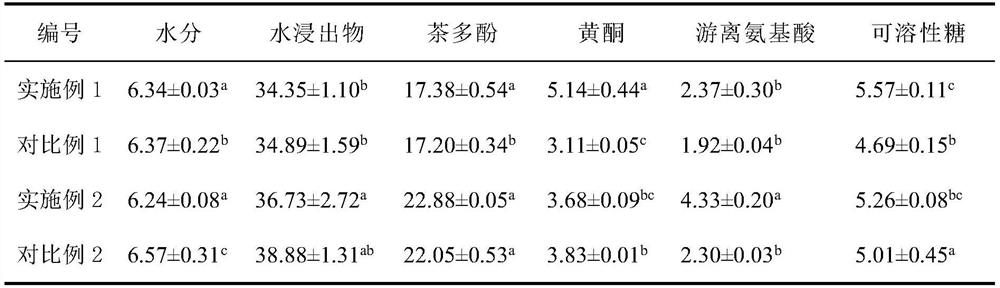

A production method and technology of white tea, which can be applied in tea treatment before extraction, climate change adaptation, etc., can solve the problems of unfavorable scale, mechanized production, large production workshop area, loose shape, etc., and achieve the improvement of free amino acids, soluble sugar and other components The effect of improving content, improving quality, and firming and even appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Dehumidification and dehydration: Close the doors and windows of the booth, use a dehumidifier to control the temperature at 22°C, and reduce the indoor air humidity to below 50%, and then evenly spread the picked Bayu Tezao fresh leaves on the In the blue tank, the thickness of the spread is 0.5cm, and when the water content is ≤ 65%, the dehydration process is ended;

[0053](2) standing and withering: the above-mentioned fresh leaves after dehumidification are spread out again, the thickness of spreading is 1cm, adopt air-conditioned room to carry out standing withering, temperature is set to 20 ℃, humidity is controlled at 55%, dehumidified 2- The 3 slots are collected into the 1 slot, and the time for standing and withering is 38h;

[0054] (3) Drying: spread the withered fresh leaves under the light at 8 to 10 o'clock in the morning on a sunny day for drying;

[0055] (4) Blast withering: return the dried tealeaves to the greening tank in time, and blast for ...

Embodiment 2

[0061] (1) Dehumidification and dehydration: Close the doors and windows of the booth, use a dehumidifier to control the temperature at 25°C, and reduce the indoor air humidity to below 45%, and then spread the picked Shuyong No. 1 single buds evenly on the In the blue tank, the thickness of the spread is 0.7cm, and when the water content is ≤62%, the dehydration process is ended;

[0062] (2) Standing and withering: the above-mentioned single buds after dehumidification are spread again, the thickness of spreading is 1.5cm, adopt air-conditioned room to carry out static withering, temperature is set to 23 ℃, humidity is controlled at 60%, dehumidified 2 - The 3 tanks are collected into the 1 tank, and the time for standing and withering is 39 hours;

[0063] (3) Drying green: spread the withered single buds under the light at 17-19 pm on a sunny day for drying;

[0064] (4) Blast withering: return the single buds after drying to the green tank in time, and blast for 40 minut...

Embodiment 3

[0070] (1) Dehumidification and dehydration: Close the doors and windows of the booth, use a dehumidifier to control the temperature at 28°C, and reduce the indoor air humidity to below 50%, and spread the picked Shuyong No. 3 single buds evenly on the In the green tank, the thickness of the spread is 1cm, and when the water content is ≤ 65%, the dehydration process is ended;

[0071] (2) standing and withering: the above-mentioned single buds after dehumidification are spread out again, the thickness of spreading is 2cm, adopt air-conditioned room to carry out standing withering, temperature is set to 25 ℃, humidity is controlled at 65%, dehumidified 2- The 3 slots are collected into the 1 slot, and the time for standing and withering is 40h;

[0072] (3) Sunshine: Sunshine 25min under the sunshade net with the single bud withered well at noon, and described sunshade net is 90cm away from the green surface of the fresh leaf stand;

[0073] (4) Blast withering: return the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com