Ag3PO4/g-C3N4 Fenton catalytic material as well as preparation method and application thereof

A catalytic material, the technology of g-c3n4, is applied in the application field of high-efficiency degradation of tetracycline hydrochloride, can solve problems such as insufficient activity and iron sludge, and achieves the effects of improving catalytic oxidation activity, good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First put urea in a muffle furnace and bake it at 550°C for 3 hours in an air atmosphere with a heating rate of 5°C / min to obtain g-C 3 N 4 . Then containing silver acetate and g-C 3 N 4 Dispersed in deionized water, where g-C 3 N 4 The mass ratio of sodium dihydrogen phosphate to silver acetate is 1:2.3. Stir in the dark for 1 hour, then add sodium dihydrogen phosphate solution to the above solution, and the molar ratio of sodium dihydrogen phosphate to silver acetate is 1:1.4. Sonicate for 1 hour under stirring and 100W power, centrifuge, and dry at 80°C for 12 hours to obtain Ag 3 PO 4 / g -C 3 N 4 Fenton-like catalytic materials.

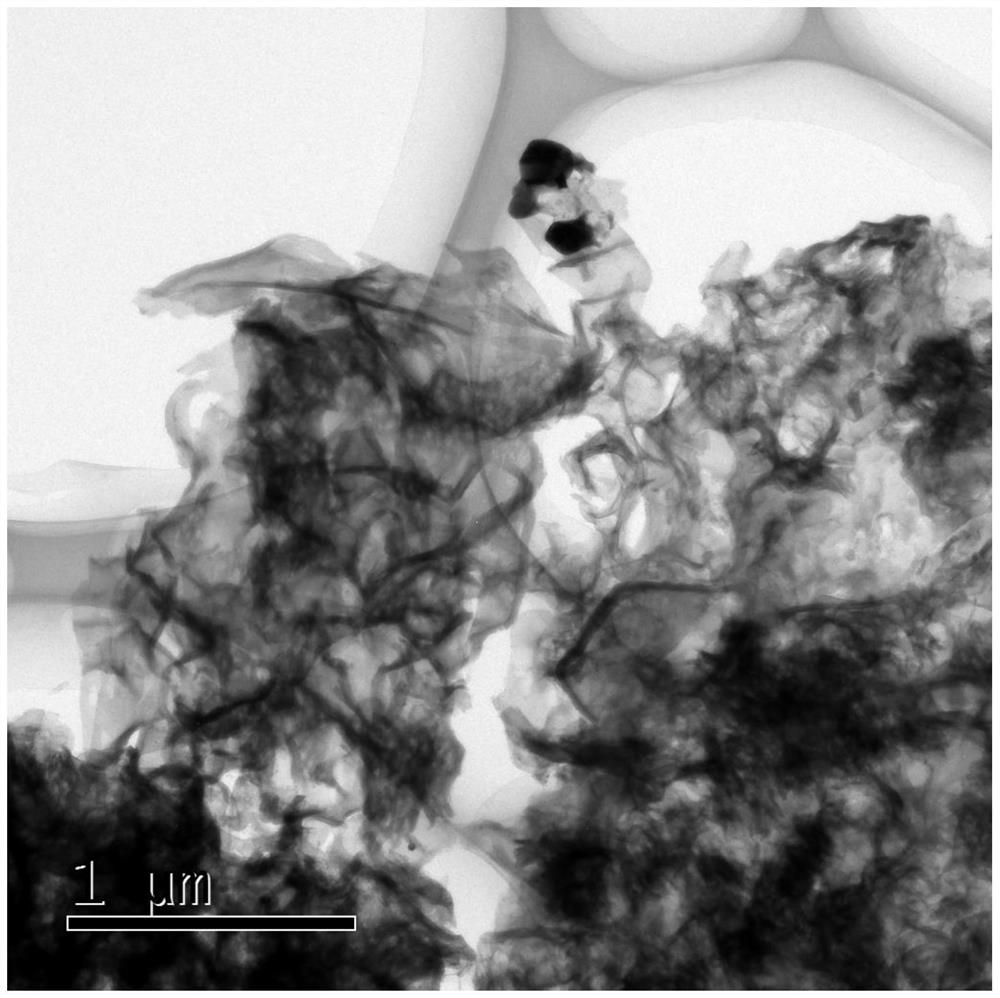

[0035] Preparation of sample transmission electron microscope photos figure 1 shows that Ag 3 PO 4 The particle size is tens of nanometers to hundreds of nanometers, g-C 3 N 4 It is a sheet / layer structure. XRD results showed that Ag 3 PO 4 is a cubic phase.

Embodiment 2

[0037] First put urea in a muffle furnace and bake it at 550°C for 3 hours in an air atmosphere with a heating rate of 3°C / min to obtain g-C 3 N 4 . Then containing silver acetate and g-C 3 N 4 Dispersed in deionized water, where g-C 3 N 4 The mass ratio of sodium dihydrogen phosphate to silver acetate is 1:4. Stir in the dark for 1 hour, then add sodium dihydrogen phosphate solution to the above solution, and the molar ratio of sodium dihydrogen phosphate to silver acetate is 1:2. Sonicate for 1 hour under stirring and 100W power, centrifuge, and dry at 100°C for 8 hours to obtain Ag 3 PO 4 / g -C 3 N 4 Fenton-like catalytic materials.

Embodiment 3

[0039] First put melamine in a muffle furnace, and bake it at 600°C for 1 hour in an air atmosphere with a heating rate of 3°C / min to obtain g-C 3 N 4 . Then add silver nitrate and g-C 3 N 4 Dispersed in deionized water, where g-C 3 N 4 The mass ratio of sodium hydrogen phosphate to silver nitrate is 1:1. Stir in the dark for 2 hours, then add sodium hydrogen phosphate solution to the above solution, and the molar ratio of sodium hydrogen phosphate to silver nitrate is 1:1. Sonicate for 2 hours under stirring and 100W power, centrifuge, and dry at 90°C for 10 hours to obtain Ag 3 PO 4 / g -C 3 N 4 Fenton-like catalytic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com