A kind of mof material with phospholipid bilayer grafted on the surface and its preparation method and application

A technology of phospholipid bilayer and lipid bilayer, which is applied in the field of membrane separation, can solve the problems of poor compatibility between fillers and polymers, and achieve the effect of good permeation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

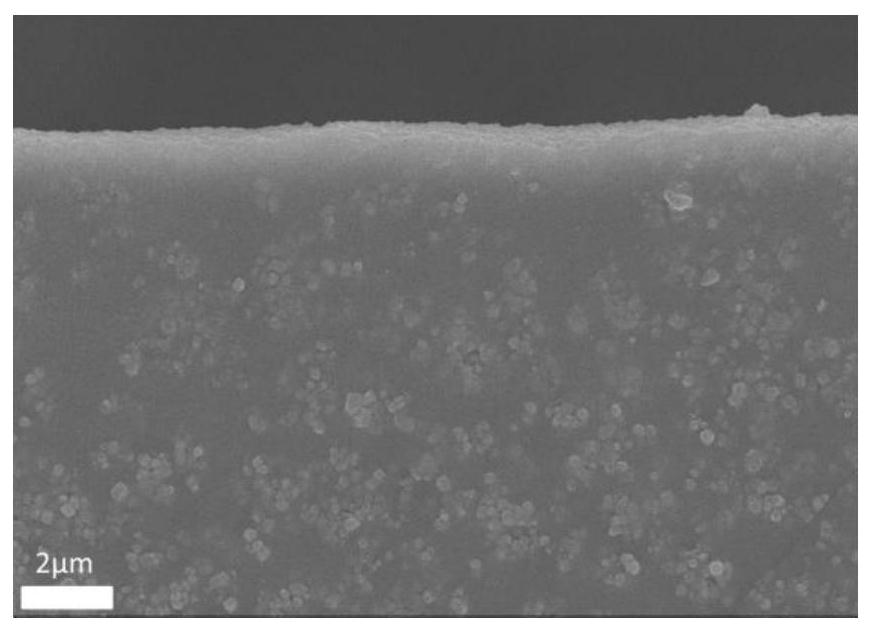

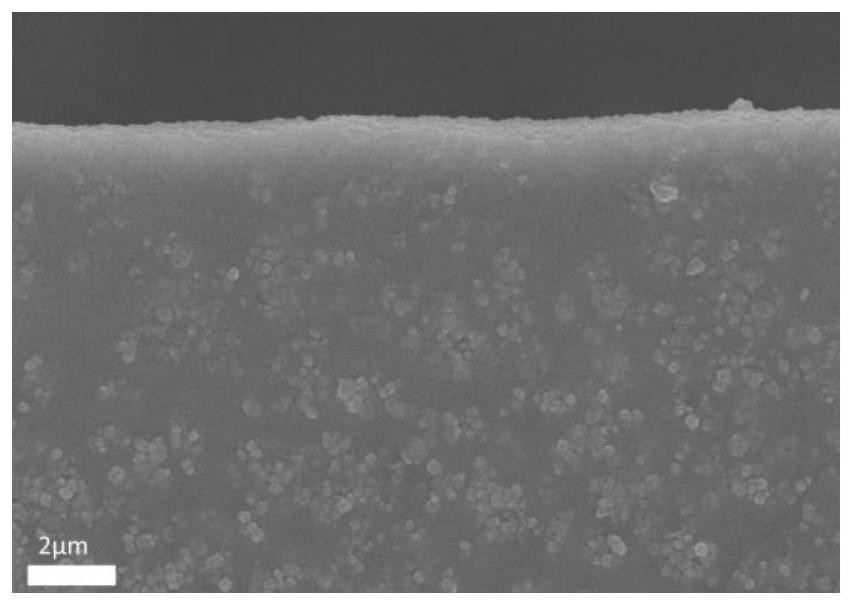

Image

Examples

preparation example 1

[0071] The preparation of parent ZIF-8 material, steps are as follows:

[0072] At room temperature, 3g of zinc nitrate hexahydrate was added to 100mL of methanol, and the resulting zinc nitrate methanol solution was directly added to 100mL of methanol solution containing 6.6g of 2-methylimidazole. After standing still for 24h, centrifuged at 9000rpm for 10min, The resulting precipitate was washed 3 times with methanol and dried in vacuo to obtain the parent ZIF-8 material.

preparation example 2

[0074] The preparation of parent ZIF-67 material, steps are as follows:

[0075] At room temperature, 3 g of cobalt nitrate hexahydrate was added to 100 mL of methanol, and the resulting cobalt nitrate methanol solution was directly added to 100 mL of methanol solution containing 6.6 g of 2-methylimidazole. After standing still for 24 h, centrifuged at 9000 rpm for 10 min, The resulting precipitate was washed three times with methanol and dried in vacuo to obtain the parent ZIF-67 material.

preparation example 3

[0077] The preparation of parent ZIF-71 material, steps are as follows:

[0078] At room temperature, 0.7 g of 4,5-dichloroimidazole was dissolved in 64 ml of N,N-dimethylformamide (DMF), and the obtained 4,5-dichloroimidazole N,N-dimethylformamide The solution was directly added to 64ml of N,N-dimethylformamide (DMF) containing 0.14g of zinc acetate dihydrate, reacted for 18h, centrifuged at 9000rpm for 10min, and the obtained precipitate was vacuum-dried overnight to obtain the parent ZIF-71 material .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com