Preparation method of selenium-rich black wheat malt oligosaccharide peptide and product of selenium-rich black wheat malt oligosaccharide peptide

A wheat malt and oligosaccharide technology is applied in the field of preparation of selenium-enriched triticale malt oligosaccharide peptides, and can solve the problems of being unsuitable for cooking and baking products, limiting the application of germinated wheat, and high amylase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] a. Germinate, dry and pulverize selenium-enriched triticale to prepare selenium-enriched triticale malt powder.

[0030] b Mix the selenium-enriched black wheat malt powder and water in step a according to 1:10 (percentage by weight) and then add it to the enzymolysis tank, turn on the agitator, set the speed at 60 rpm, heat to 90° C. with water steam, and Cook for 30 minutes to obtain selenium-enriched triticale mash.

[0031] c The selenium-enriched triticale mash in step b is cooled to 60°C for the first time, the pH meter is opened, and sodium hydroxide is added to the enzymolysis tank with a peristaltic pump to adjust the pH value to 7.0, and then 1wt% amylase ( Accounting for 1% of the weight of selenium-enriched triticale malt powder), saccharification and hydrolysis for 2 hours to obtain saccharification and hydrolysis of selenium-enriched triticale mash.

[0032] d The temperature of the saccharified and ...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] a. Germinate, dry and pulverize selenium-enriched triticale to prepare selenium-enriched triticale malt powder.

[0038] b Mix the selenium-enriched black wheat malt powder and water in step a according to 1:10 (percentage by weight) and add it to the enzymolysis tank, turn on the agitator, set the speed at 60 rpm, heat to 90° C. with water steam, and Cook for 30 minutes to obtain selenium-enriched triticale mash.

[0039] c The selenium-enriched triticale mash in step b is cooled to 70°C for the first time, the pH meter is opened, and sodium hydroxide is added to the enzymolysis tank with a peristaltic pump to adjust the pH value to 8.0, and then 3wt% amylase ( Accounting for 3% of the weight of selenium-enriched triticale malt powder), saccharification and hydrolysis for 3 hours to obtain saccharification and hydrolysis selenium-enrichment triticale mash.

[0040] d The temperature of the saccharified and hydrolyz...

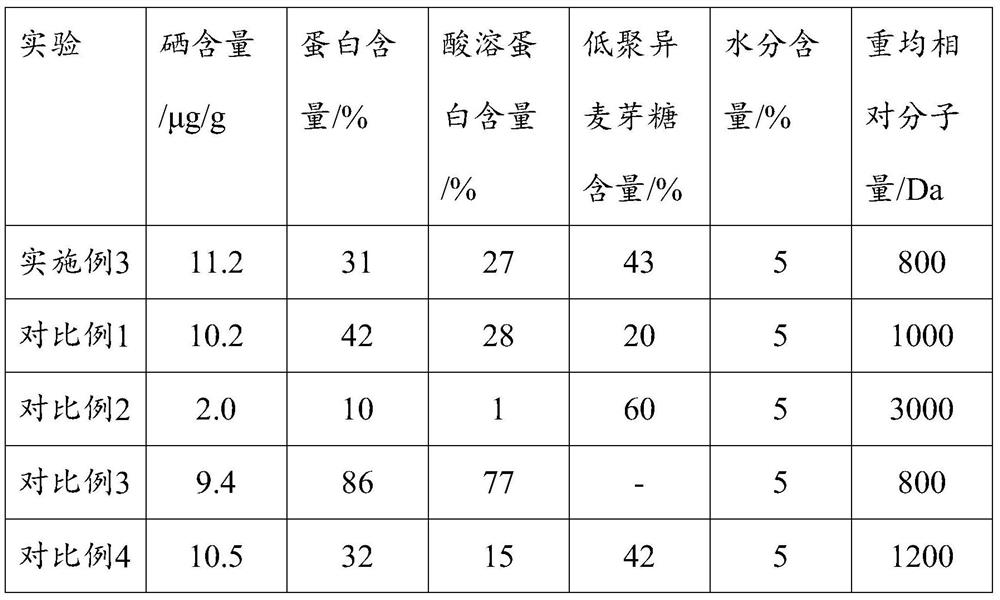

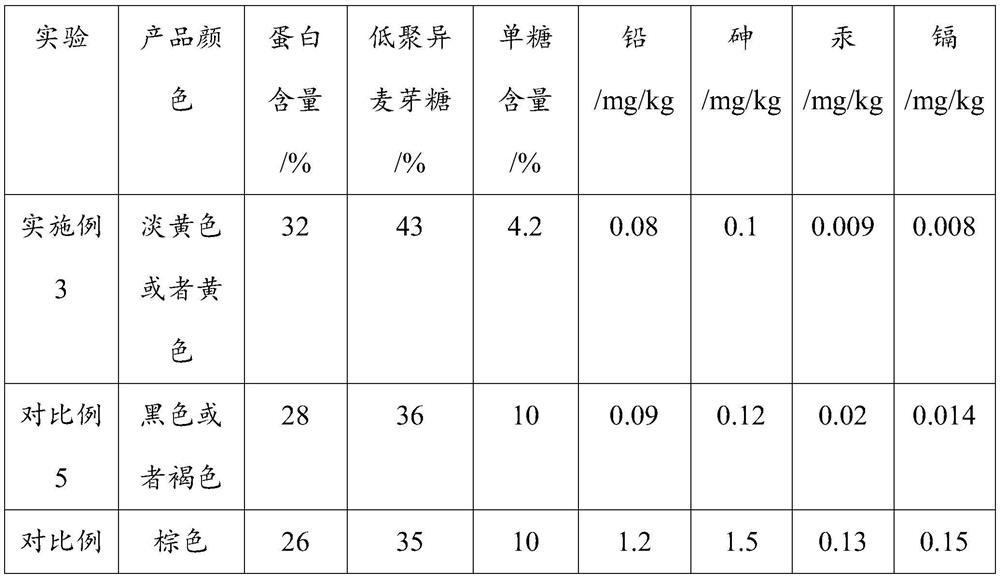

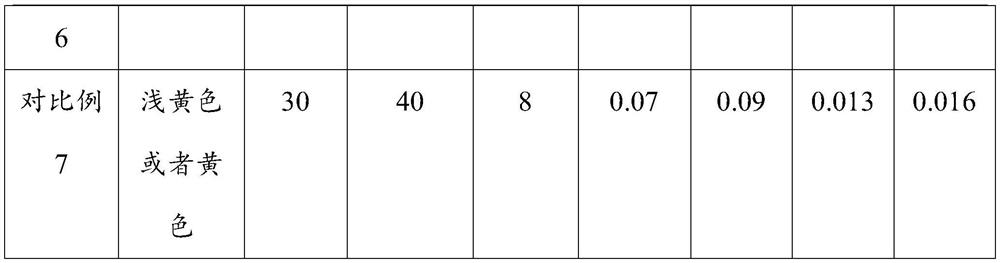

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] a. Germinate, dry and pulverize selenium-enriched triticale to prepare selenium-enriched triticale malt powder.

[0046] b Mix the selenium-enriched black wheat malt powder and water in step a according to 1:10 (percentage by weight) and then add it to the enzymolysis tank, turn on the agitator, set the speed at 60 rpm, heat to 90° C. with water steam, and Cook for 30 minutes to obtain selenium-enriched triticale mash.

[0047] c The selenium-enriched triticale mash in step b is cooled to 70°C for the first time, the pH meter is opened, and sodium hydroxide is added to the enzymolysis tank with a peristaltic pump to adjust the pH value to 8.0, and then 2wt% amylase ( Calculated according to the weight of selenium-enriched triticale malt powder), saccharified and hydrolyzed for 3 hours to obtain saccharified and hydrolyzed selenium-enriched triticale mash.

[0048] d The temperature of the saccharified and hydrolyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com