Method for preparing (001) preferred orientation low-melting-point bismuth film by molecular beam epitaxy technology

A technology of molecular beam epitaxy and preferred orientation, which is applied in the field of molecular beam epitaxy to prepare low-melting bismuth metal thin films, achieving the effects of good flatness, low surface roughness and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

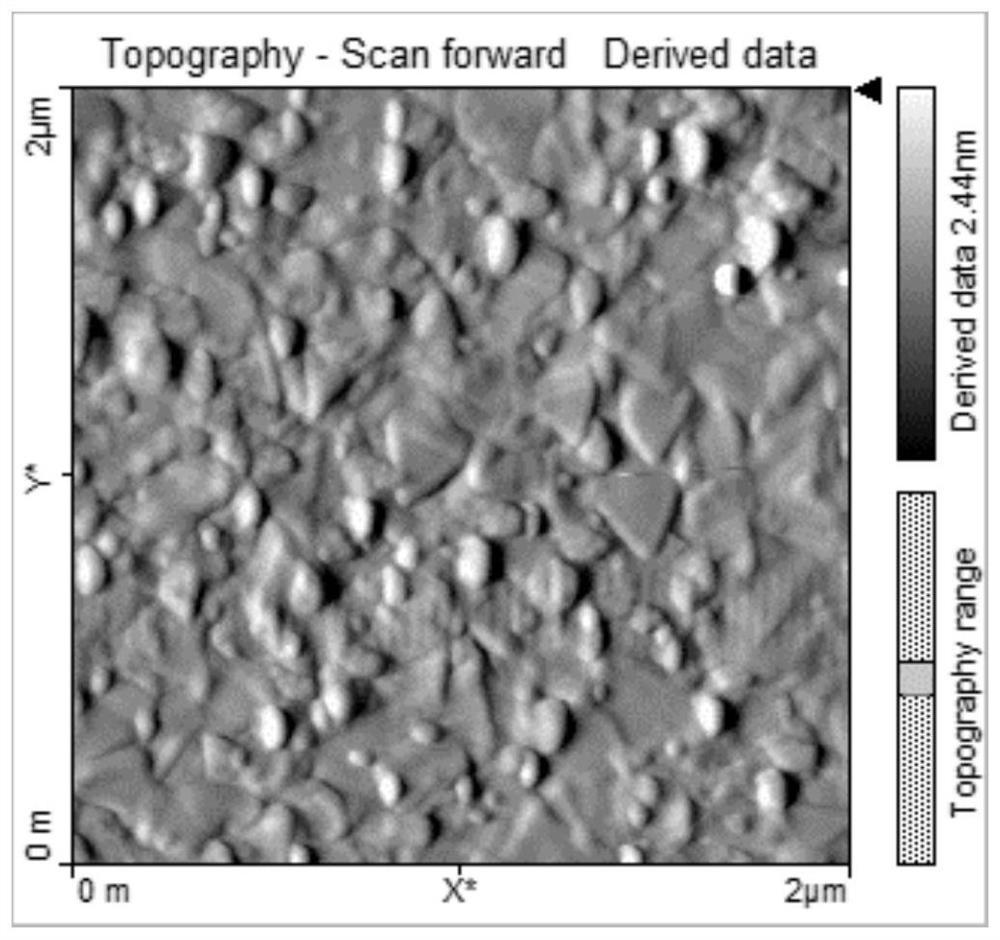

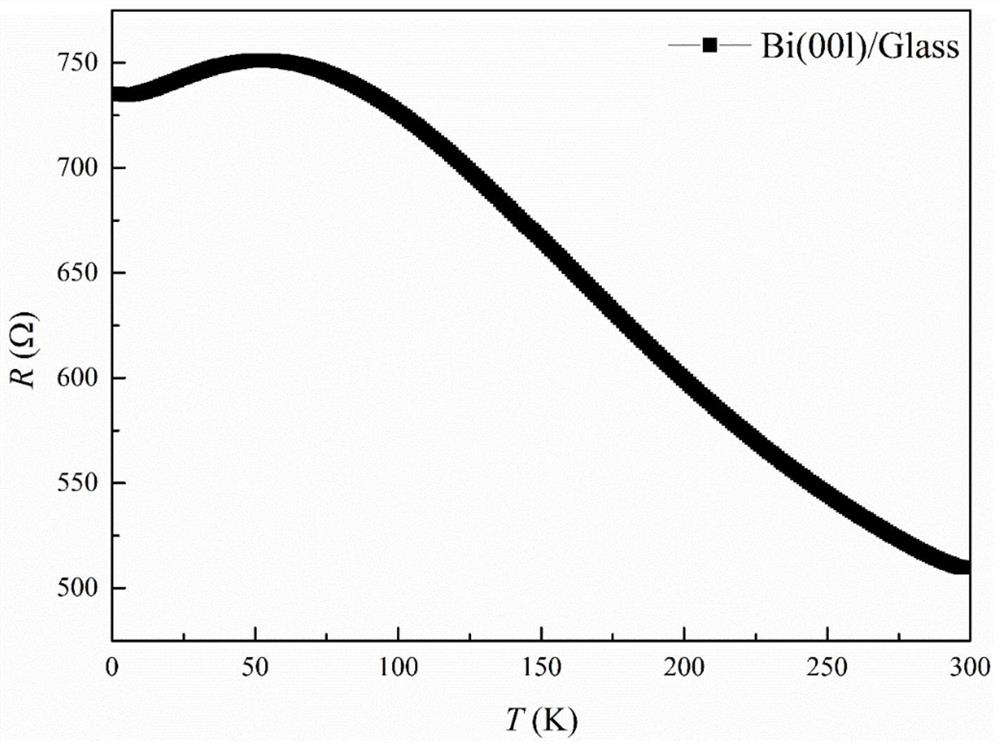

[0027] 1) Use a glass substrate as the substrate for preparing the bismuth film, put it in the processing chamber and transfer it to the growth chamber of the molecular beam epitaxy system;

[0028] 2) The growth chamber pressure is less than 5.0×10 -6 Pa starts to preheat the substrate;

[0029] 3) Adjust the temperature of the bismuth beam source furnace to 560°C and the substrate temperature to 70°C;

[0030] 4) Open the bismuth beam source furnace and the substrate shutter baffle, spray the bismuth beam onto the heated substrate, and deposit for 3 hours;

[0031] 5) Turn on the reflective high-energy electron diffractometer to observe the diffraction fringes of the film. The fringes are clear and sharp, indicating that the grown bismuth film is of good quality and the surface is smooth;

[0032] 6) Close the bismuth beam source furnace and the substrate shutter shutter, reduce the temperature of the bismuth beam source furnace and the substrate to room temperature, and o...

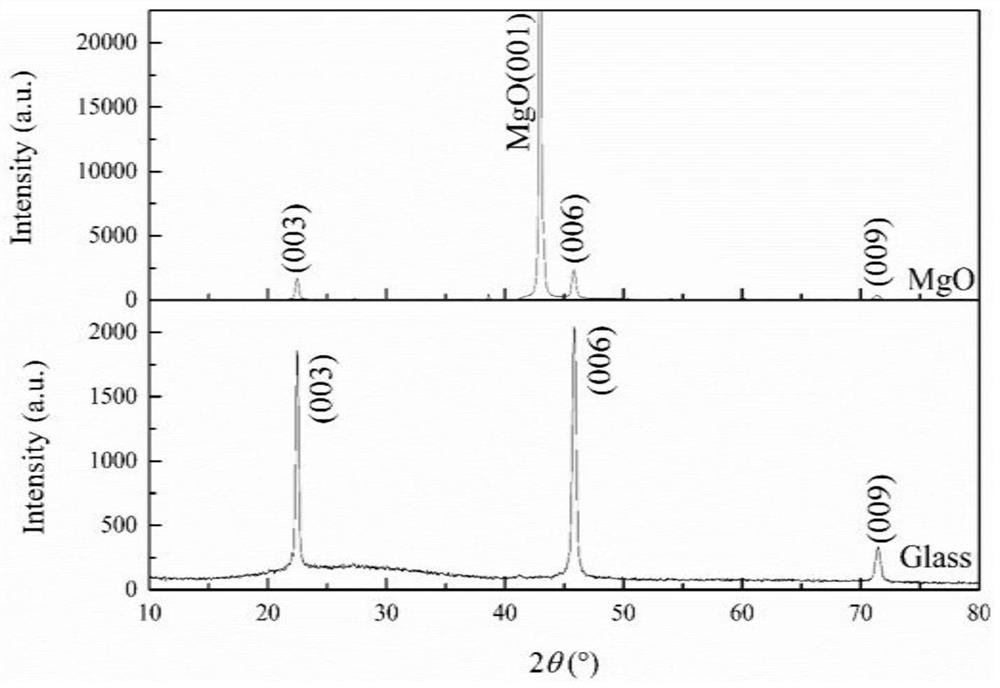

Embodiment 2

[0035] 1) Use the magnesium oxide substrate as the substrate for preparing the bismuth film, put it in the processing chamber and transfer it to the growth chamber of the molecular beam epitaxy system;

[0036] 2) The growth chamber pressure is less than 5.0×10 -6 Pa began to preheat the substrate, and turned on the reflection high-energy electron diffractometer to observe the substrate diffraction fringes;

[0037] 3) Adjust the temperature of the bismuth beam source furnace to 560°C and the substrate temperature to 70°C;

[0038] 4) Open the bismuth beam source furnace and the substrate shutter baffle, spray the bismuth beam onto the heated substrate, and deposit for 3 hours;

[0039] 5) Turn on the reflective high-energy electron diffractometer to observe the diffraction fringes of the film. The fringes are clear and sharp, indicating that the grown bismuth film is of good quality and the surface is smooth;

[0040] 6) Close the bismuth beam source furnace and the substra...

Embodiment 3

[0043] 1) Use the strontium titania substrate as the substrate for preparing the bismuth film, put it in the processing chamber and transfer it to the growth chamber of the molecular beam epitaxy system;

[0044] 2) The growth chamber pressure is less than 5.0×10 -6 Pa began to preheat the substrate, and turned on the reflection high-energy electron diffractometer to observe the substrate diffraction fringes;

[0045] 3) Adjust the temperature of the bismuth beam source furnace to 490°C and the substrate temperature to 30°C;

[0046] 4) Open the bismuth beam source furnace and the substrate shutter baffle, spray the bismuth beam onto the heated substrate, and deposit for 3 hours;

[0047] 5) Turn on the reflective high-energy electron diffractometer to observe the diffraction fringes of the film. The fringes are clear and sharp, indicating that the grown bismuth film is of good quality and the surface is smooth;

[0048] 6) Close the bismuth beam source furnace and the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com