A kind of silk fibroin/octacalcium phosphate composite bone scaffold material and its preparation method

A technology of silk fibroin and octacalcium phosphate, applied in the field of materials, to achieve good degradation performance and mechanical properties, increase strength, and enhance osteogenic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Dissolve silk fibroin in 50 mL of 40 mM calcium nitrate solution to prepare a solution with a silk fibroin concentration of 0.1% by weight.

[0029] 2. Prepare 50 mL of a sodium dihydrogen phosphate solution with a concentration of 40 mM.

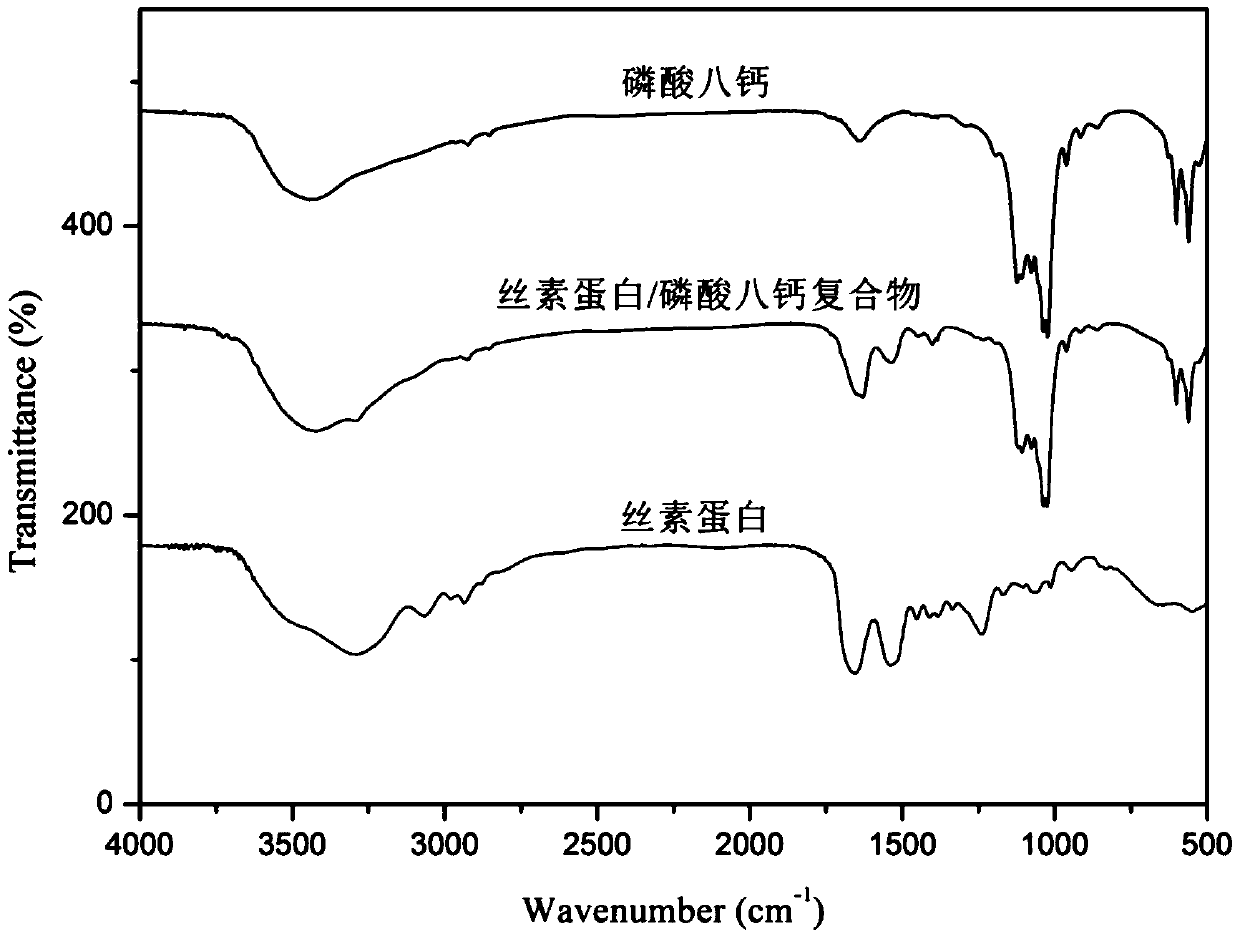

[0030] 3. Under 68°C and stirring conditions, slowly add the silk fibroin-containing calcium nitrate solution prepared in step 1) to the sodium dihydrogen phosphate solution prepared in step 2), and continue to stir for 1 hour to finally obtain a white precipitate Things. The white precipitate was washed three times by centrifugation, placed at -80°C for 1 day, and freeze-dried for 2 days to obtain a silk fibroin / octacalcium phosphate complex. The infrared spectrum is as follows figure 1 Shown

[0031] 4. Grind the silk fibroin / octacalcium phosphate composite obtained in step 3) into a powder with a mortar, weigh out 20 mg of the powder, then mix it with 1 mL of silk fibroin solution with a concentration of 6 wt%, and pour it into a cyl...

Embodiment 2

[0034] 1. Dissolve silk fibroin in 50 mL of 80 mM calcium nitrate solution to prepare a solution with a silk fibroin concentration of 0.5 wt%.

[0035] 2. Prepare 50 mL of a sodium dihydrogen phosphate solution with a concentration of 80 mM.

[0036] 3. Under stirring conditions at 70°C, slowly add the silk fibroin-containing calcium nitrate solution prepared in step 1) to the sodium dihydrogen phosphate solution prepared in step 2), and continue to stir for 1.5 hours to obtain a white precipitate. Things. After centrifugal washing the white precipitate for three times, place it at -80°C for 1 day and freeze-dry for 2 days to obtain a silk fibroin / octacalcium phosphate complex;

[0037] 4. Grind the silk fibroin / octacalcium phosphate composite obtained in step 3) into a powder with a mortar, weigh out 50 mg of the powder, then mix it with 1 mL of silk fibroin solution with a concentration of 10 wt%, and pour it into a cylindrical mold. Placed at -80°C for 1 day and freeze-dried for...

Embodiment 3

[0040] 1. Dissolve silk fibroin in 120 mL of 40 mM calcium nitrate solution to prepare a solution with a silk fibroin concentration of 2 wt%.

[0041] 2. Prepare 120 mL of sodium dihydrogen phosphate solution with a concentration of 40 mM.

[0042] 3. Under the condition of heating and stirring at 68°C, slowly add the silk fibroin-containing calcium nitrate solution prepared in step 1) to the sodium dihydrogen phosphate solution prepared in step 2), and continue to stir for 1.5 hours to obtain a white precipitate. Things. After centrifugal washing the white precipitate for three times, place it at -80°C for 1 day and freeze-dry for 2 days to obtain a silk fibroin / octacalcium phosphate complex;

[0043] 4. Grind the silk fibroin / octacalcium phosphate composite obtained in step 3) into a powder with a mortar, weigh 100 mg of the powder, and then mix it with 1 mL of silk fibroin solution with a concentration of 10 wt%, and pour it into a cylindrical mold. Placed at -80°C for 1 day and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com