Light-emitting diode chip manufacturing method capable of improving brightness

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve the problems of low quality of LED epitaxial InGaN/GaN multi-quantum wells, low quality of multi-quantum well growth, and affecting LED energy-saving effects, etc. , to achieve the effect of improving carrier recombination efficiency, improving chip brightness, and improving LED light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

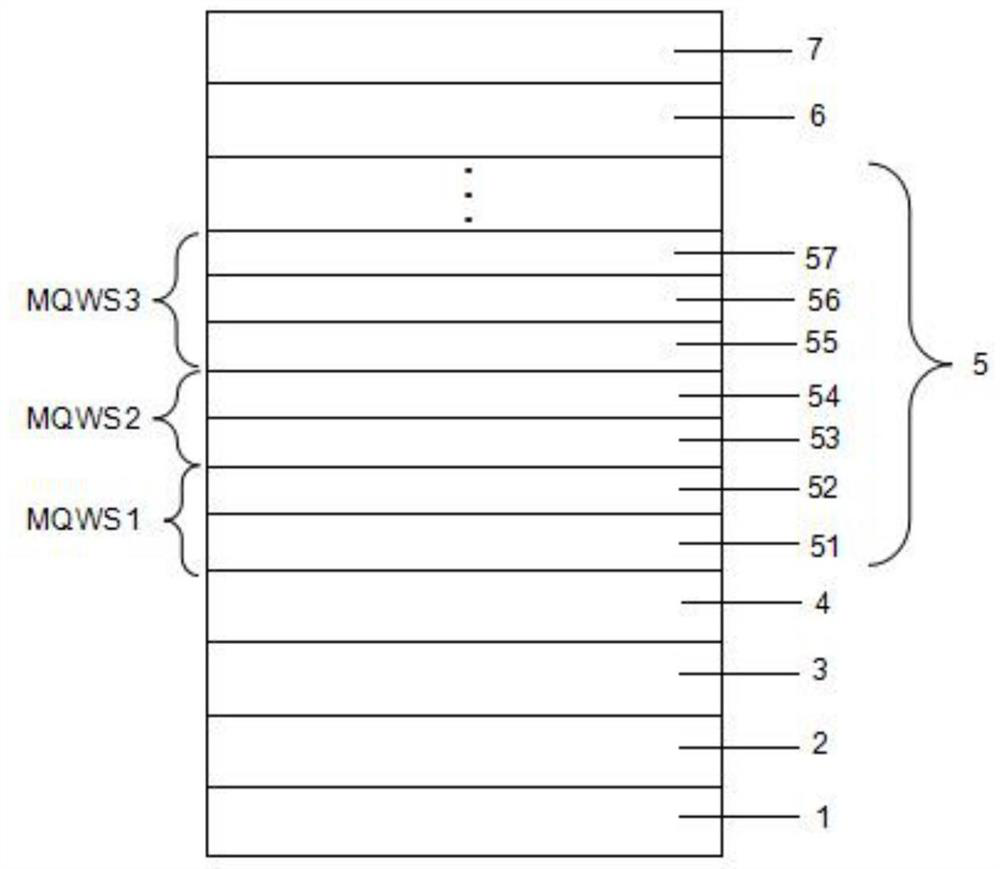

[0048] This embodiment adopts the light-emitting diode chip manufacturing method for improving brightness provided by the present invention, adopts MOCVD to grow GaN-based LED epitaxial wafers, and uses high-purity H 2 or high purity N 2 or high purity H 2 and high purity N 2 The mixed gas as the carrier gas, high-purity NH 3 As the N source, the metal-organic source trimethylgallium (TMGa) is used as the gallium source, trimethylindium (TMIn) is used as the indium source, and the N-type dopant is silane (SiH 4 ), trimethylaluminum (TMAl) as the aluminum source, and the P-type dopant as magnesium dicene (CP 2 Mg), the reaction pressure is between 70mbar and 600mbar. The specific growth method is as follows (for the epitaxial structure, please refer to figure 1 ):

[0049] A method for manufacturing a light-emitting diode chip for improving brightness, which sequentially includes: processing a sapphire substrate 1, growing a low-temperature GaN buffer layer 2, growing a n...

Embodiment 2

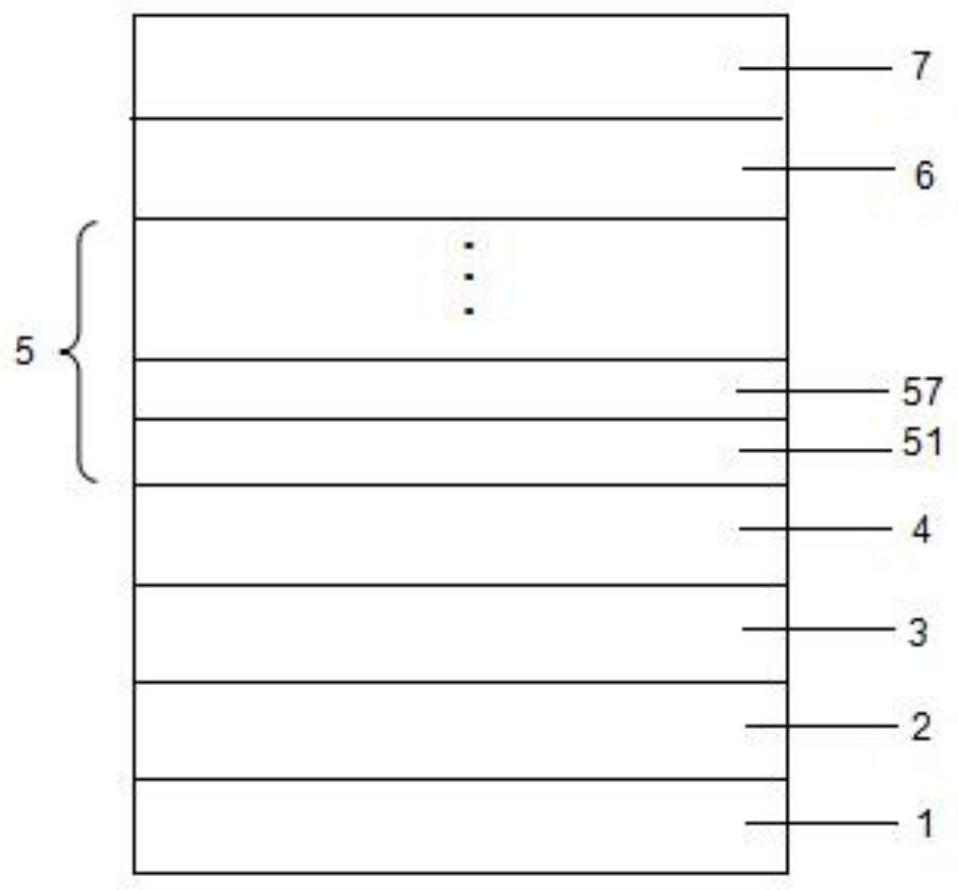

[0085] Comparative examples are provided below, that is, the growth method of the traditional LED epitaxial structure (for the epitaxial structure, please refer to figure 2 ).

[0086] Step 1: At a temperature of 1000-1100°C and a reaction chamber pressure of 100-300mbar, feed 100-130L / min of H 2 Under the conditions, process the sapphire substrate for 5-10 minutes.

[0087] Step 2: growing a low-temperature GaN buffer layer 2 and forming irregular small islands in the low-temperature GaN buffer layer 2 .

[0088] Specifically, the step 2 is further as follows:

[0089] At a temperature of 500-600°C and a reaction chamber pressure of 300-600mbar, 10000-20000sccm of NH is introduced 3 , 50-100sccm TMGa, 100-130L / min H 2 Under the condition of , growing the low-temperature GaN buffer layer 2 on the sapphire substrate 1, the thickness of the low-temperature GaN buffer layer 2 is 20-40nm;

[0090] At a temperature of 1000-1100°C and a reaction chamber pressure of 300-600mbar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com