Curable silicone composition, cured product thereof, and method for producing same

A silicone and curable technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, heat-activated film/sheet, etc., can solve damage, can not solve the stress relaxation characteristics of functional filler cured products, easy to produce warping, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

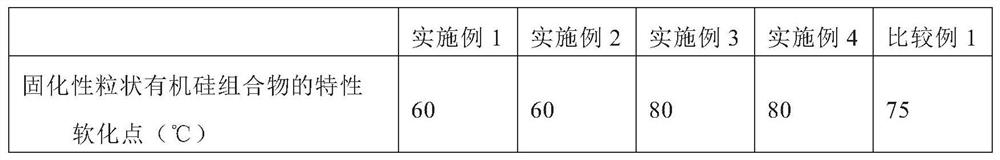

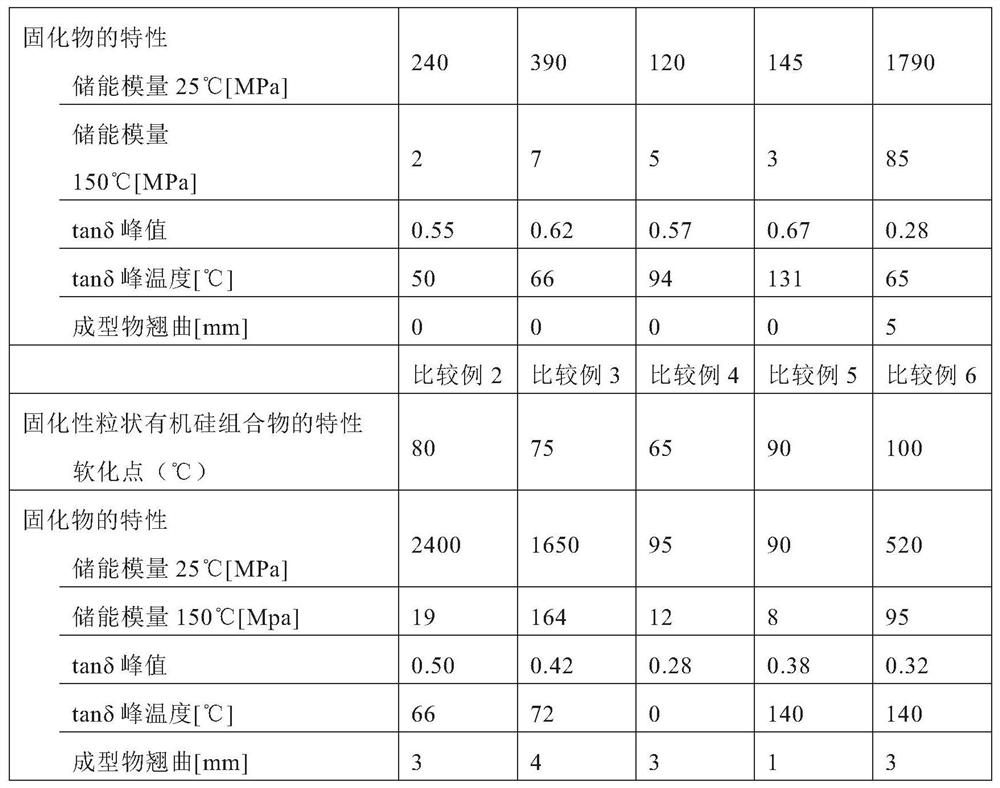

[0312] The hot-melt curable silicone composition of the present invention and its production method will be described in detail using examples and comparative examples. In addition, in the formula, Me, Ph, and Vi represent a methyl group, a phenyl group, and a vinyl group, respectively. In addition, about the curable silicone composition of each Example and a comparative example, the softening point was measured by the following method. In addition, the curable silicone composition was heated at 150° C. for 2 hours to prepare a cured product, and the storage elastic modulus, loss tangent (tan δ), and warpage of the molded product were measured by the following methods. The results are shown in Table 1.

[0313] [Softening point of curable granular silicone composition]

[0314] The curable granular silicone composition is molded into cylindrical particles. The pellets were placed on a heating plate set at 25° C. to 100° C., and a load of 100 grams was continuously pressed...

reference example 1

[0321] Into a 1L flask, put into a white solid at 25°C, the average unit formula (PhSiO 3 / 2 ) 0.80 (Me 2 ViSiO 1 / 2 ) 0.20 270.5 g of a 55% by mass-toluene solution of the resinous polyorganosiloxane represented by the formula HMe 2 SiO(Ph 2 SiO)SiMe 2 21.3 g of diphenylsiloxane (content of hydrogen atoms bonded to silicon atoms = 0.6% by mass) with dimethylhydrogensiloxane groups at both ends of the molecular chain represented by H and having a viscosity of 5 mPa·s (relative to the above-mentioned 1 mole of vinyl groups in resinous polyorganosiloxane, 0.5 moles of silicon atoms bonded to hydrogen atoms in this component), and 1,3-divinyltetramethyldisiloxane complex of platinum 0.43 g of 1,3-divinyltetramethyldisiloxane solution (platinum metal content=approximately 4000 ppm) of the product (relative to this liquid mixture, the amount of platinum metal is 10 ppm by mass unit), at room temperature Stir evenly. Then, raise the temperature in the flask to 100°C in a...

reference example 2

[0323] Put into a 1L flask, which is a white solid at 25°C, which is represented by the average unit formula (Me 2 ViSiO 1 / 2 ) 0.05 (Me 3 SiO 1 / 2 ) 0.39 (SiO 4 / 2 ) 0.56 (HO 1 / 2 ) 0.02 270.5 g of 55% by mass-xylene solution of polyorganosiloxane resin and 1,3-divinyltetramethyldisiloxane complex of platinum Disiloxane solution (content of platinum metal=approximately 4000ppm) 0.375g was uniformly stirred at room temperature (25°C) to prepare a polyorganosiloxane resin (2) containing 10ppm of platinum metal by mass unit. xylene solution. In addition, this polyorganosiloxane resin (2) does not soften or melt even when heated to 200° C., and does not have thermal fusibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com